Method for reducing content of purine substances in soybean milk through salting-out, conversion and macroporous resin absorption

A technology of macroporous resin and substance content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Determination method of purine substances:

[0021] Pretreatment: Take 10mL sample in a 50mL flask, add 10mL perchloric acid, hydrolyze in a water bath at 100°C for 1 hour, then cool in an ice bath, adjust the pH to 7 with 6mol / L NaOH solution, H 3 PO 4 Adjust the pH to 4, set the volume to 100mL, mix thoroughly and pass through a 0.22μm filter membrane for testing.

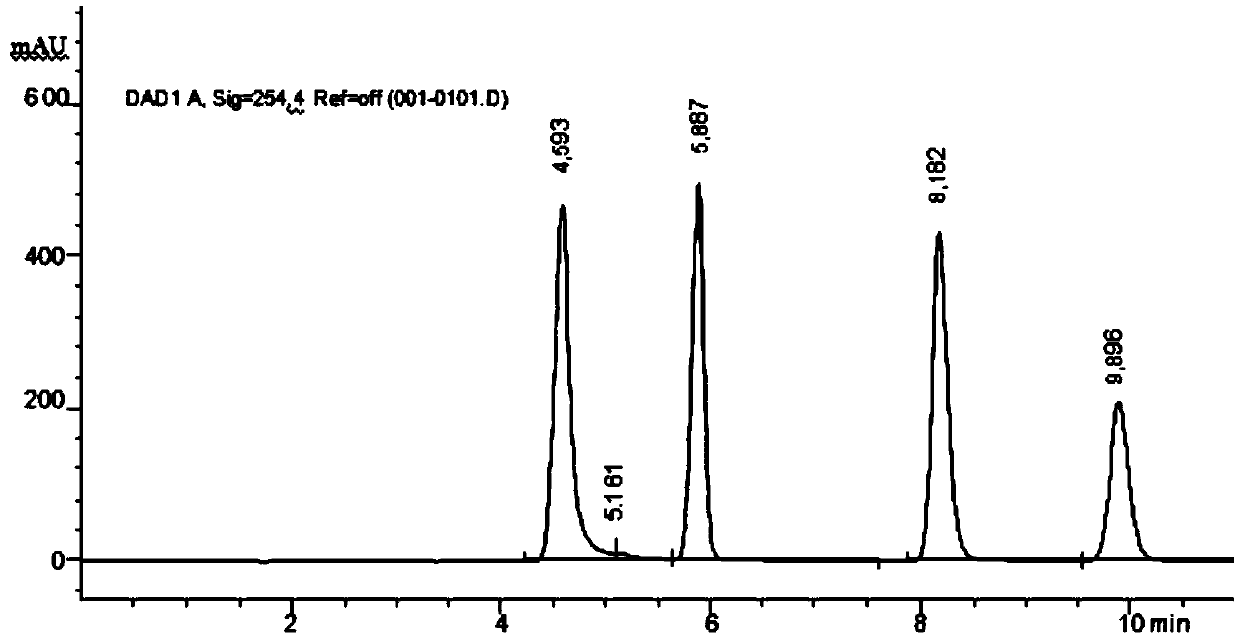

[0022] Instrument and method: high performance liquid chromatography, wavelength 254nm, flow rate 1.0mL / min, 0.02mol / L potassium dihydrogen phosphate, mobile phase pH 3.4, respectively determine adenine, guanine, yellow in soybean milk samples Purine and hypoxanthine content. See the attached standard spectrum figure 1 .

Embodiment 2

[0024] A kind of salting-out-conversion-macroporous resin adsorption method of the present invention reduces the content of purines in soybean milk, comprising the following steps:

[0025] (1) Preparation of soybean milk: Soak soybeans and water at a mass volume ratio of 1:10 (1 kg of soybeans and 10 L of water), soak for 12 hours, and refine.

[0026] (2) Salting-out treatment: add 4.0 g of food-grade calcium chloride to every 1000 mL of soybean milk, shake it by hand, and let it stand for 1 hour for salting-out.

[0027] (3) Chemical conversion treatment: Add 0.15ml of food additive dimethyl dicarbonate dropwise to every 1000mL of the sample after salting out. During the dropping process, shake it by hand continuously, then heat to 55°C and stir for 2h.

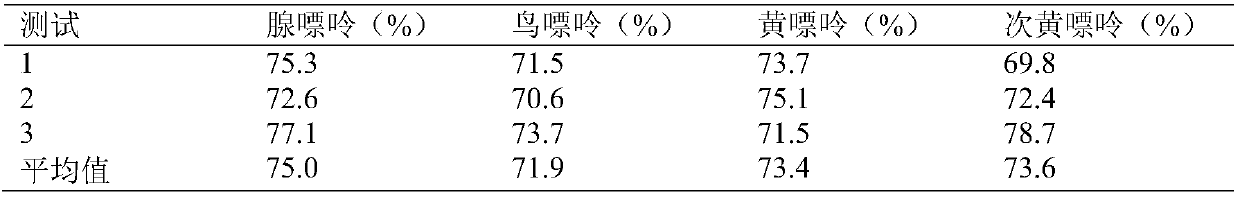

[0028] (4) Adsorption and centrifugation treatment: add macroporous resin (XAD-2) 6.0g / 1000mL to the reacted sample, stir and adsorb for 1 hour, and centrifuge at low speed to precipitate. This method can remove 71.9%-75....

Embodiment 3

[0033] A kind of salting-out-conversion-macroporous resin adsorption method of the present invention reduces the content of purines in soybean milk, comprising the following steps:

[0034] (1) Preparation of soymilk: soak for 12 hours according to the mass volume ratio of soybeans and water (1kg of soybeans, 15L of water), and refine.

[0035] (2) Salting-out treatment: add 4.0 g of food-grade calcium chloride to every 1000 mL of soybean milk, shake it by hand, and let it stand for 1 hour for salting-out.

[0036] (3) Chemical conversion treatment: Add 0.15ml of food additive dimethyl dicarbonate dropwise to every 1000mL of the sample after salting out. During the dropping process, shake it by hand continuously, then heat to 55°C and stir for 2h.

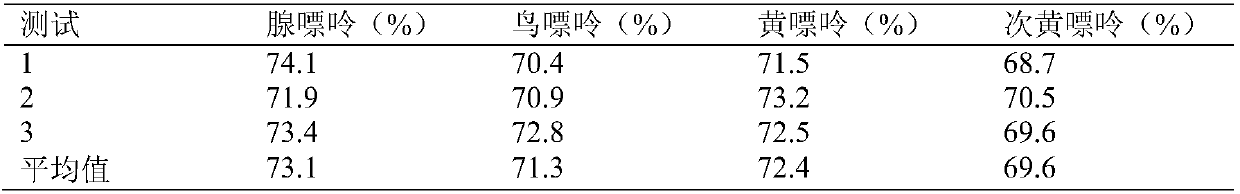

[0037] (4) Adsorption and centrifugation treatment: add macroporous resin (XAD-2) 6.0g / 1000mL to the reacted sample, stir and adsorb for 1 hour, and centrifuge at low speed to precipitate. This method can remove 69.6%-73.1% of pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com