Molybdenum precipitation wastewater treatment method and molybdenum precipitation residue treatment method

A technology for vanadium precipitation wastewater and its treatment method, which is applied in the field of vanadium precipitation wastewater treatment and vanadium precipitation waste slag treatment. It can solve the problems of poor wastewater treatment effect and complicated process flow, and achieve the benefits of operation and maintenance, offsetting costs, Eliminate the effect of clogging or corroding equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

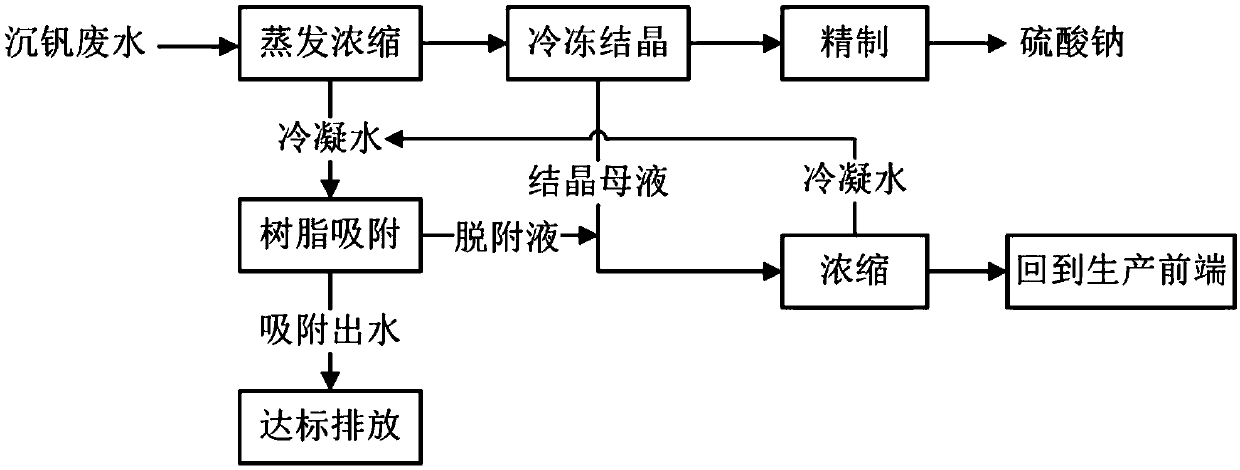

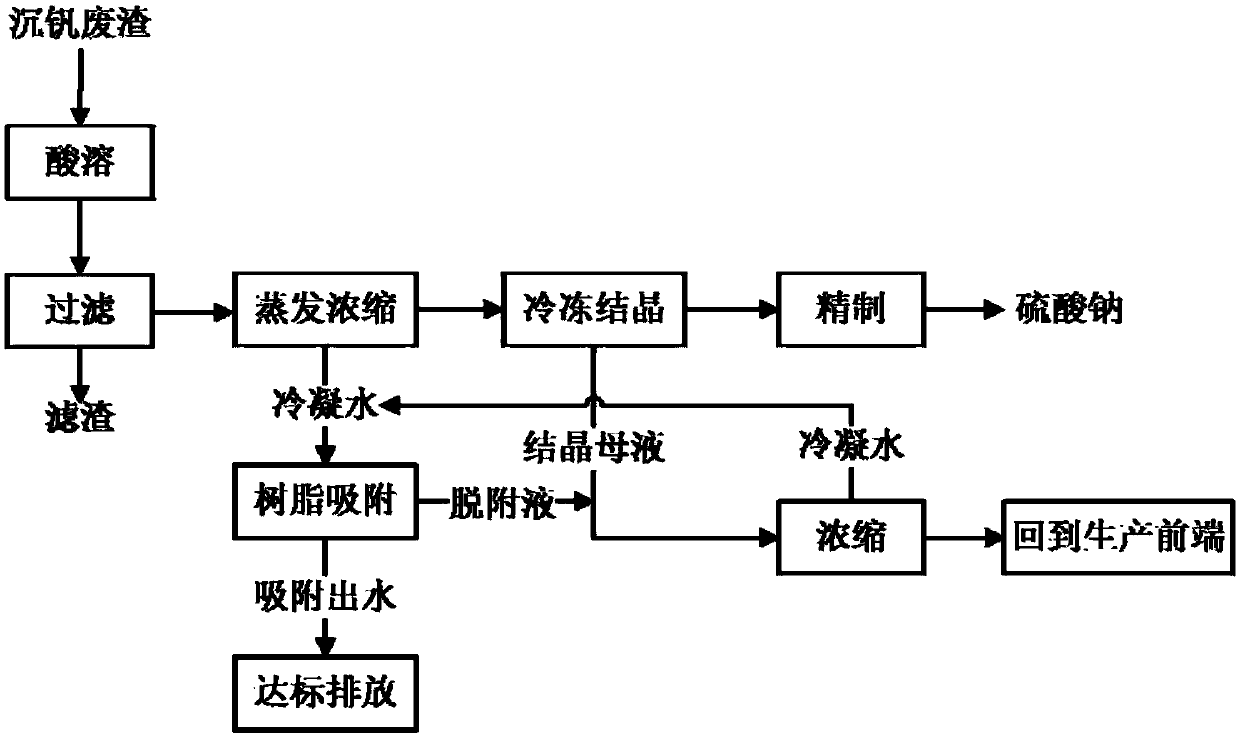

[0039] combine figure 1 , a kind of treatment method of vanadium precipitation wastewater of the present embodiment, comprises the following steps:

[0040] Step 1, take a certain amount of vanadium precipitation wastewater, containing 2460mg / L of chromium, 673mg / L of vanadium, Na + 46200mg / L, NH 4 + 7560mg / L, pH 1.73, the vanadium precipitation wastewater is evaporated and concentrated at 60°C through the evaporation equipment, and the condensed water is collected as long as no crystals are precipitated during the evaporation process;

[0041] Step 2, freeze and crystallize the concentrated mother liquor obtained in step 1 to obtain crystallization mother liquor and crystals, refine the crystals to obtain anhydrous sodium sulfate solids, and return the waste liquid generated during the refining process to the raw water and mix with the raw water; this embodiment The medium freeze crystallization adopts the method of two-stage cooling freeze crystallization. The temperature...

Embodiment 2

[0053] The treatment method of a kind of vanadium precipitation waste water of present embodiment, its step is basically the same as embodiment 1, and its difference is: in the present embodiment, vanadium precipitation waste water contains chromium 2430mg / L, vanadium 687mg / L, Na + 46269mg / L, NH 4 + 7560mg / L, pH 1.72, step 1, the vanadium precipitation wastewater is evaporated and concentrated at 100°C through the evaporation equipment, and the evaporation concentration multiple is based on the fact that no crystals are precipitated, and the condensed water is collected;

[0054] Step 2, freeze and crystallize the concentrated mother liquor obtained in step 1 to obtain crystallization mother liquor and crystals, refine the crystals to obtain anhydrous sodium sulfate solids, and return the waste liquid generated during the refining process to the raw water and mix with the raw water; this embodiment The medium freeze crystallization adopts the method of two-stage cooling freez...

Embodiment 3

[0061] Containing 2430mg / L of chromium, 687mg / L of vanadium, Na + 46269mg / L, NH 4 + 7560mg / L, pH 1.72, step 1, the vanadium precipitation wastewater is evaporated and concentrated at 80°C through the evaporation equipment, and the evaporation concentration multiple is based on the fact that no crystals are precipitated, and the condensed water is collected;

[0062] Step 2, freeze and crystallize the concentrated mother liquor obtained in step 1 to obtain crystallization mother liquor and crystals, refine the crystals to obtain anhydrous sodium sulfate solids, and return the waste liquid generated during the refining process to the raw water and mix with the raw water; this embodiment The medium freezing crystallization adopts the method of two-stage cooling and freezing crystallization. The first-stage freezing crystallization temperature is lowered from 80°C to 45°C and kept at 45°C for 1 hour. The second-stage freezing crystallization temperature is lowered from 45°C to 0°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com