Catalytic cracking process and catalytic cracking system

A catalytic cracking and process technology, which is applied in the field of catalytic cracking process and system, can solve the problem of no further conversion of light hydrocarbons, and achieve the effects of promoting cracking again, increasing the conversion rate of heavy oil, and improving catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

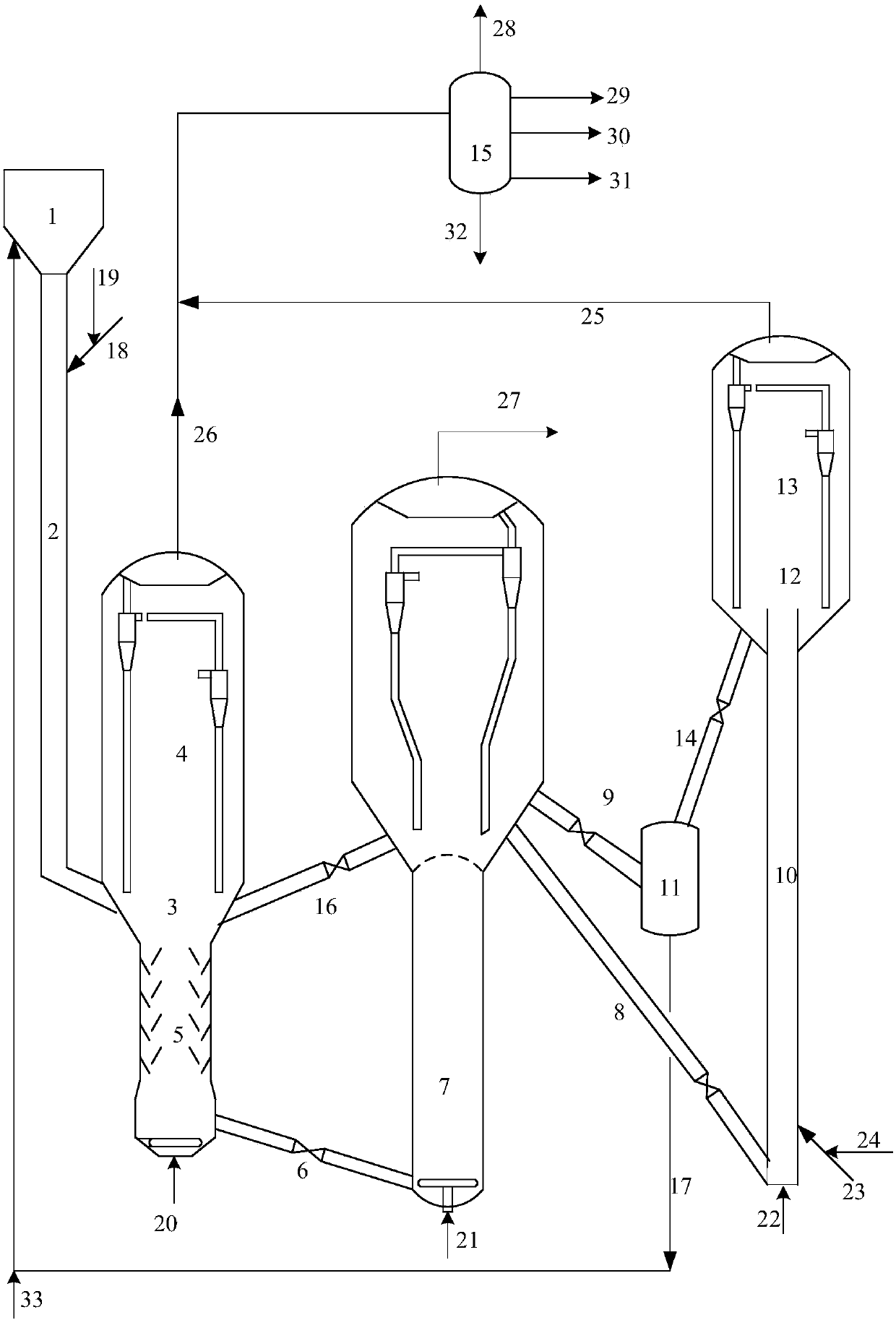

[0064] According to the present invention, the second product and the second spent catalyst leaving the first fluidized bed reactor enter the settling section, and after settling to separate the second spent catalyst carried therein, the second product is introduced into a subsequent product separation device. In the product separation device, the second product is separated to obtain dry gas, liquefied gas, gasoline, diesel oil and oil slurry. The second fluidized bed reactor and the first fluidized bed reactor may share a set of product separation device. At this time, the two streams of products are mixed and then introduced into the product separation device. For example figure 1 As shown, the system can also include a product separation device 15, the inlet of the product separation device 15 can be communicated with the product outlet of the first fluidized bed reactor 3 and the product outlet of the second fluidized bed reactor 12 , the product separation device 15 may...

Embodiment 1

[0070] The test was carried out in a medium-sized catalytic cracking unit. The device includes a set of independent reaction regeneration system: the reactor is a downcomer reactor plus a fluidized bed combination reactor, the inner diameter of the riser is 16 mm, and the length is 3200 mm, and the fluidized bed reaction at the bottom outlet of the downcomer reactor The diameter (inner diameter) of the fluidized bed reactor is 64 mm and the height is 600 mm. The catalyst used is MMC-2 catalyst, which cracks the raw materials shown in Table 1; the oil and gas after the reaction are separated from the catalyst, and the catalyst enters the stripper for stripping and then enters the regenerator for regeneration, and the regenerated catalyst leaves the regenerator in two ways , all the way into the fluidized bed reactor, increase the reaction temperature and the ratio of agent to oil in the fluidized bed reactor. The other way enters the catalyst mixing tank, and then enters the c...

Embodiment 2

[0074] Referring to Example 1, the difference is that the regenerated catalyst leaves the regenerator in three ways, one way enters the fluidized bed reactor, the other way enters the catalyst mixing tank, and then enters the catalyst tank at the top of the downcomer reactor, and the third way enters the lifting tube reactor. Riser reactor internal diameter is 12 millimeters, and length is 2200 millimeters, and the catalyzer that adopts is MMC-2 catalyzer, to the light gasoline (distillation range is 30-85 ℃ that is 30-85 ℃, olefin content is 52 weight percents) rich in olefins from product separation unit , the weight of light gasoline accounts for 15% by weight of the weight of heavy raw materials) for cracking, and the resulting oil gas and catalyst mixture is subjected to gas-solid separation in a gas-solid separation device. The separated catalyst enters the catalyst mixing tank to be mixed with the high-temperature regenerant, and then sent to the catalyst tank at the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com