Cracking auxiliary agent for improving catalytic cracking low-carbon olefin concentration

A technology of additives and concentration, applied in catalytic cracking, hydrocarbon cracking to hydrocarbon production, molecular sieve catalyst, etc., can solve the problems of low propylene concentration, high dry gas and coke yield, low propylene selectivity, etc., and improve octane number. , the effect of improving selectivity and improving the conversion rate of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

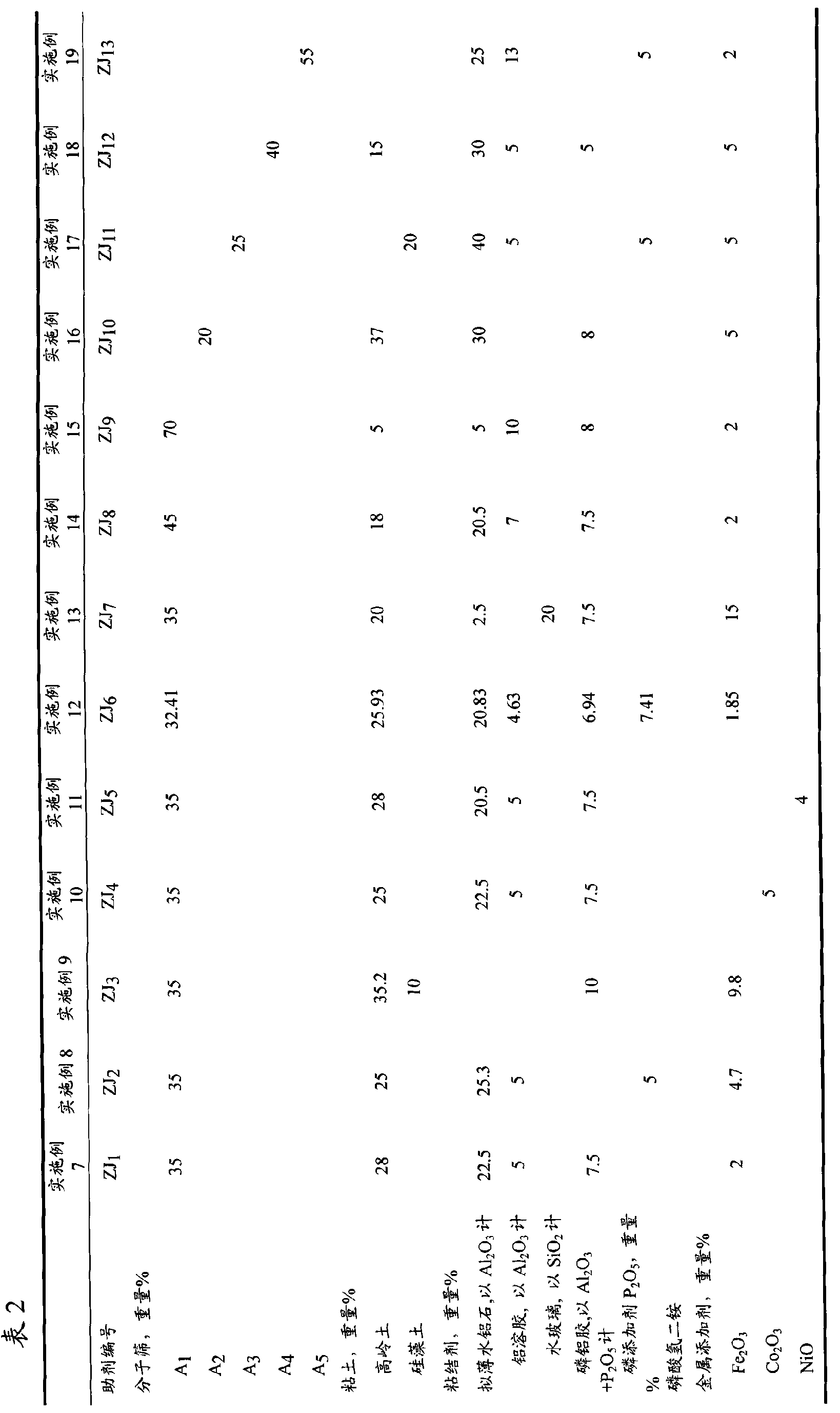

[0030] The preparation method of the modified MFI molecular sieve of the present invention is to modify the MFI molecular sieve containing phosphorus and transition metals with a silicon-containing compound, including mixing the roasted molecular sieve with MFI structure containing phosphorus and transition metals with a silicon source , and then keep the resulting mixture at 145-190° C. for 2-80 hours to carry out reaction crystallization (also called crystallization). SiO 2 The weight ratio of silicon source in terms of silicon source to the MFI molecular sieve containing phosphorus and transition metals in dry basis is 0.03~0.3:1, preferably 0.05~0.15:1; the reaction crystallization temperature is preferably 150-190°C, more preferably 170-190°C; reaction crystallization time is preferably 5-50 hours, more preferably 12-24 hours.

[0031] Mix the calcined molecular sieve with MFI structure containing phosphorus and transition metals with the silicon source, preferably add a...

specific Embodiment approach

[0036] A specific embodiment of the preparation method provided by the invention includes:

[0037] (1) According to molecular sieve: ammonium salt: H 2 O=1: (0.1 ~ 1): (5 ~ 10) weight ratio Sodium type molecular sieve with MFI structure is exchanged at room temperature to 100 ° C for 0.3 ~ 1 hour and then filtered and dried;

[0038] (2) Impregnating and modifying the ammonium-exchanged molecular sieve with a phosphorus-containing compound solution and a solution containing a transition metal compound, then drying and roasting; the roasting temperature is 400-800° C.; The metal compound solution impregnates the ammonium-exchanged molecular sieve, which may be impregnated with a solution containing both a phosphorus compound and a transition metal compound, or may be impregnated separately with a solution containing a phosphorus compound and a solution containing a transition metal compound; the impregnation Can be carried out one or more times, preferably, impregnation with ...

Embodiment 1

[0045] 5kg NH 4 Cl was dissolved in 100kg of water, and 10kg (dry basis) of crystallization product ZSM-5 molecular sieve (produced by Sinopec Catalyst Qilu Branch Company, produced by amine method, SiO 2 / Al 2 o 3 =50), after exchanging at 90°C for 0.5h, filtered to obtain a filter cake; 0.9kg H 3 PO 4 (concentration 85% by weight) and 0.81kgFe(NO 3 ) 3 9H 2 O was dissolved in 9kg of water, and the impregnating solution and filter cake were mixed and impregnated, dried, and roasted at 550°C for 2 hours; take 1kg of the above-mentioned roasted molecular sieve, and mix it with 0.536kg of tetraethyl orthosilicate (Beijing Chemical Reagent Company, Analytical grade, SiO 2 content 28% by weight), 0.333kg tetrapropylammonium bromide (Guangzhou Dayou fine chemical factory production, analytical purity, 99%) and the mixture of 1.2L water are mixed, are placed in the crystallization kettle that contains polytetrafluoroethylene liner, After static crystallization at 150°C for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com