Preparation method of ordered nano-array nitrogen-sulfur double-doped compound carbon rod material and lithium-sulfur battery

A nano-array and nano-carbon rod technology is used in the preparation of ordered nano-array nitrogen-sulfur double-doped carbon-sulfur composite carbon rod materials, and in the field of lithium-sulfur batteries, which can solve the problem that it is difficult to meet the requirements of secondary batteries and the practical application of fuel cells. , limit the large-scale application and other problems, to achieve the effect of improving electrochemical performance, low cost and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

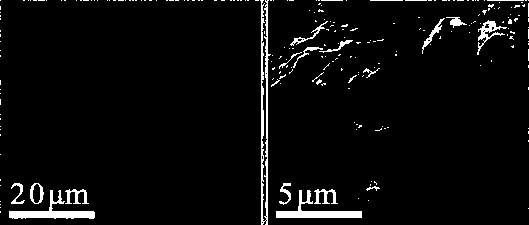

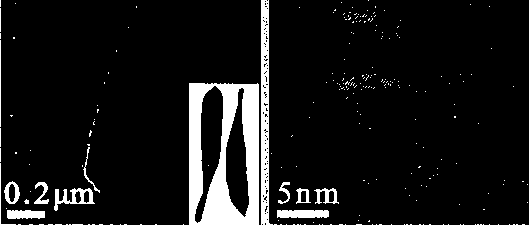

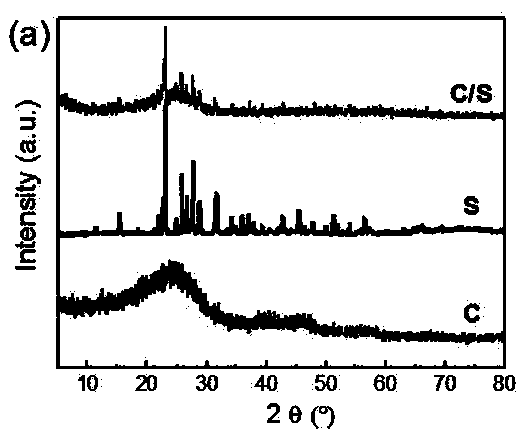

[0037] This embodiment provides a method for preparing an ordered nano-array nitrogen-sulfur double-doped carbon-sulfur composite carbon rod material, including the following steps:

[0038] S1. Mix and grind the tea seed cake and KOH at a weight ratio of 1:4, put it into a stainless steel autoclave, add 60mL of distilled water and stir evenly, add 20mL of formaldehyde solution with a concentration of 36.5%, seal the autoclave and place it at 80°C 3 hours in a blast drying oven, then react at 180°C for 12 hours, after cooling to room temperature, take out the sample, filter, wash and dry with distilled water to obtain ordered nanoarray precursor carbon rods;

[0039] S2. Place the dried ordered nanoarray precursor carbon rod obtained in step S1 in a quartz boat and place it in a tube furnace, and calcinate it at 800° C. for 2 hours under the protection of argon flow, and use dilute nitric acid and Wash the sample thoroughly with distilled water to obtain an ordered array of ca...

Embodiment 2

[0043] This embodiment provides a method for preparing an ordered nano-array nitrogen-sulfur double-doped carbon-sulfur composite carbon rod material, including the following steps:

[0044] S1. Mix and grind nut shells and KOH at a weight ratio of 1:3, put them into a stainless steel autoclave, add 60mL of distilled water and stir evenly, add 20mL of formaldehyde solution with a concentration of 36.5%, seal the autoclave and place it in a drum at 80°C Air drying oven for 3 hours, then react at 180°C for 12 hours, after cooling to room temperature, take out the sample, filter, wash and dry with distilled water to obtain ordered nanoarray precursor carbon rods;

[0045] S2. Place the dried ordered nanoarray precursor carbon rod obtained in step S1 in a quartz boat and place it in a tube furnace, and calcinate it at 800° C. for 1 hour under the protection of argon flow, and use dilute nitric acid and Wash the sample thoroughly with distilled water to obtain an ordered array of car...

Embodiment 3

[0049] This embodiment provides a method for preparing an ordered nano-array nitrogen-sulfur double-doped carbon-sulfur composite carbon rod material, including the following steps:

[0050] S1. Mix and grind the peanut cake and KOH at a weight ratio of 1:4, put it into a stainless steel autoclave, add 60mL of distilled water and stir evenly, add 20mL of formaldehyde solution with a concentration of 36.5%, seal the autoclave and place it in a drum at 80°C Air drying oven for 3 hours, then react at 180°C for 12 hours, after cooling to room temperature, take out the sample, filter, wash and dry with distilled water to obtain ordered nanoarray precursor carbon rods;

[0051] S2. Place the dried ordered nanoarray precursor carbon rod obtained in step S1 in a quartz boat and place it in a tube furnace, and calcinate it at 800° C. for 1 hour under the protection of argon flow, and use dilute nitric acid and Wash the sample thoroughly with distilled water to obtain an ordered array o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com