Polyphenol fermentation liquid with high anti-oxidation activity and preparation process thereof

A technology of oxidation activity and preparation process, applied in the fields of tea, food science, application, etc., can solve the problems of damage of polyphenols at extraction temperature, complicated process and high cost, and achieve the effect of weakening the influence of microorganisms, excellent preparation process and reducing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

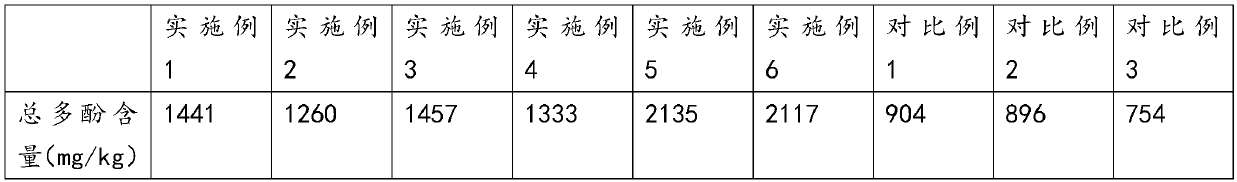

Examples

Embodiment 1

[0031] Step a. Soak 25 parts of tea leaves, 5 parts of onion, 10 parts of purple cabbage, 5 parts of spinach, and 1350 parts of water for 3.5 hours to obtain mixture M1.

[0032] Step b. Soak 15 parts of apples, 12 parts of lemons, and 5 parts of grapes in 65 parts of water for 1 hour to obtain mixture M2.

[0033] Step c, the mixture M1 is subjected to microwave leaching, the power is 400W, the time is 10min, the number of times is 4 times, and the interval is 1min.

[0034] Step d, the mixture M2 is subjected to microwave leaching, the power is 380W, the time is 2min, the number of times is 3 times, and the time interval is 30s.

[0035] The D1 and D2 that step e, step c and step d obtain are mixed, add white granulated sugar 5%, inoculate Bifidobacterium adolescent simultaneously (viable bacteria number 1×10 9 cfu / g, inoculum size 0.1‰) and Lactobacillus acidophilus (viable bacteria number 1X10 8 cfu / g, inoculum size 0.05‰), fermentation temperature 35°C, fermentation tim...

Embodiment 2

[0040] Step a. Soak 28 parts of tea leaves, 3 parts of onion, 8 parts of purple cabbage and 4 parts of spinach in 1300 parts of water for 3 hours to obtain mixture M1.

[0041] Step b. Soak 12 parts of apples, 10 parts of lemons, and 6 parts of grapes in 60 parts of water for 0.75 hours to obtain mixture M2.

[0042] Step c, the mixture M1 is subjected to microwave extraction, the power is 400W, the time is 15min, the number of times is 3 times, and the interval is 1min.

[0043] Step d, the mixture M2 is subjected to microwave extraction, the power is 380W, the time is 1min, the number of times is 3 times, and the time interval is 30s.

[0044] The D1 and D2 that step e, step c and step d obtain are mixed, add white granulated sugar 5%, inoculate Bifidobacterium adolescent simultaneously (viable bacteria number 1×10 9 cfu / g, inoculum size 0.08‰) and Lactobacillus acidophilus (viable bacteria number 1X10 8 cfu / g, inoculum size 0.04‰), fermentation temperature 35°C, fermentat...

Embodiment 3

[0049] Step a. Soak 28 parts of tea leaves, 5 parts of onion, 10 parts of purple cabbage and 5 parts of spinach in 1450 parts of water for 3.5 hours to obtain mixture M1.

[0050]Step b. Soak 15 parts of apples, 14 parts of lemons, and 7 parts of grapes in 70 parts of water for 1 hour to obtain mixture M2.

[0051] Step c, the mixture M1 is subjected to microwave leaching, the power is 400W, the time is 10min, the number of times is 4 times, and the interval is 1min.

[0052] Step d, the mixture M2 is subjected to microwave extraction, the power is 380W, the time is 1.5min, the number of times is 3 times, and the time interval is 30s.

[0053] The D1 and D2 that step e, step c and step d obtain are mixed, add white granulated sugar 4%, inoculate Bifidobacterium adolescent simultaneously (viable bacteria number 1×10 9 cfu / g, inoculum size 0.07‰) and Lactobacillus acidophilus (viable bacteria number 1X10 8 cfu / g, inoculum size 0.05‰), fermentation temperature 35°C, fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com