Method for selectively removing outer surface acid site of molecular sieve based catalyst

A molecular sieve and catalyst technology, applied in the field of industrial catalysis, can solve the problems of low selectivity and fast deactivation rate, and achieve the effect of improving selectivity, low cost and improving shape-selective catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

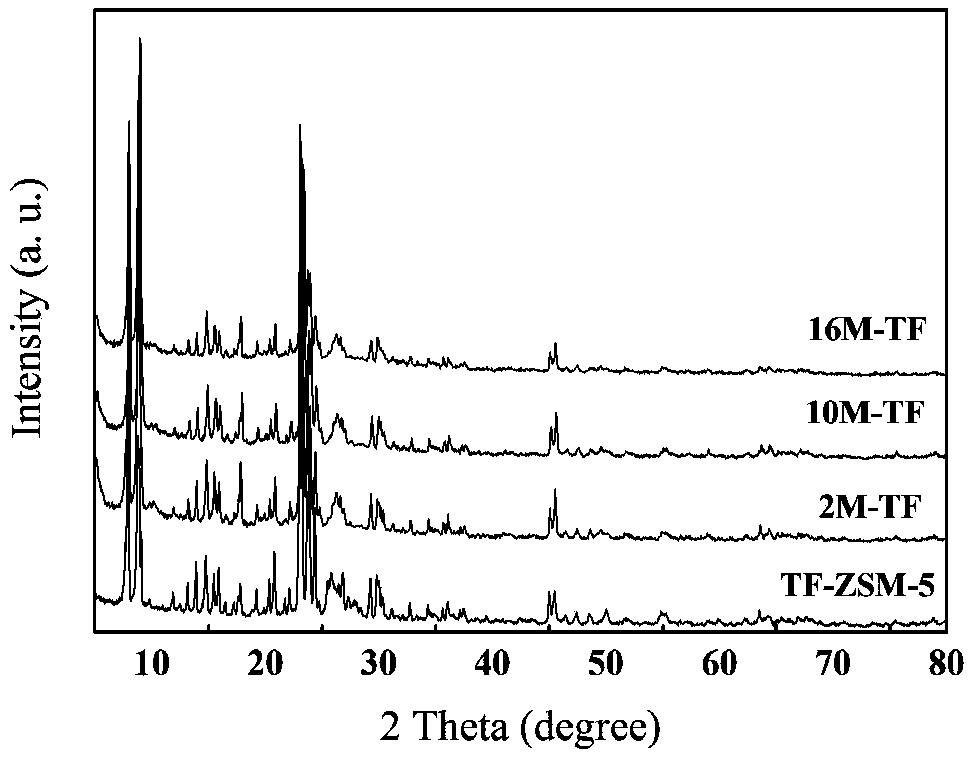

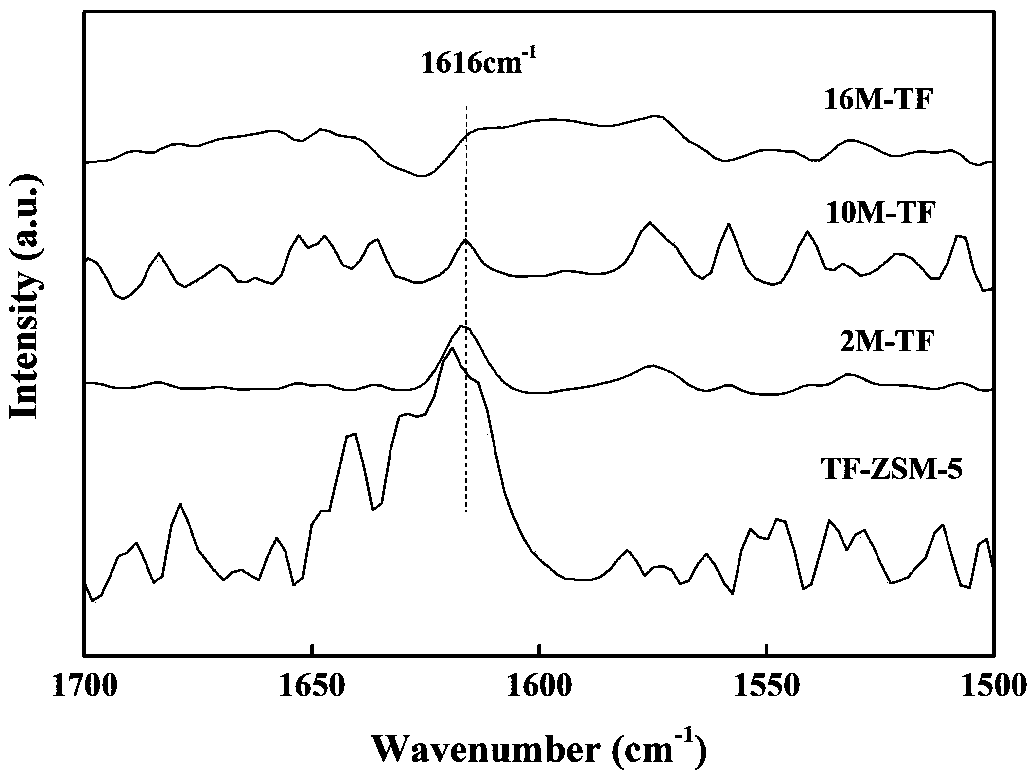

[0019] No template method ZSM-5 is prepared by hydrothermal method, the method is as follows: mix sodium metaaluminate, sodium hydroxide and distilled water in a beaker, slowly add silicon source (fumed silica) under high-speed stirring, and mix to form The molar composition is 100SiO 2 -1.6Al 2 o 3 -23NaOH-3000H 2 The sol of O was aged for 12 hours and transferred to a stainless steel crystallization kettle lined with polytetrafluoroethylene. After crystallization at 170°C for 96 hours, take it out, wash it, and bake it at 550°C for 7 hours to obtain ZSM-5 by the template-free method. See the attached X-ray diffraction pattern. figure 2 , its 2,6-di-tert-butylpyridine adsorption infrared spectrum is as follows image 3 shown.

[0020] The obtained ZSM-5 molecular sieves were ion-exchanged into H-type ZSM-5, treated with nM nitric acid solution at 180°C for 24 hours, the samples were taken out, filtered and dried, then put into a muffle furnace at 550°C Roasting in the ...

Embodiment 2

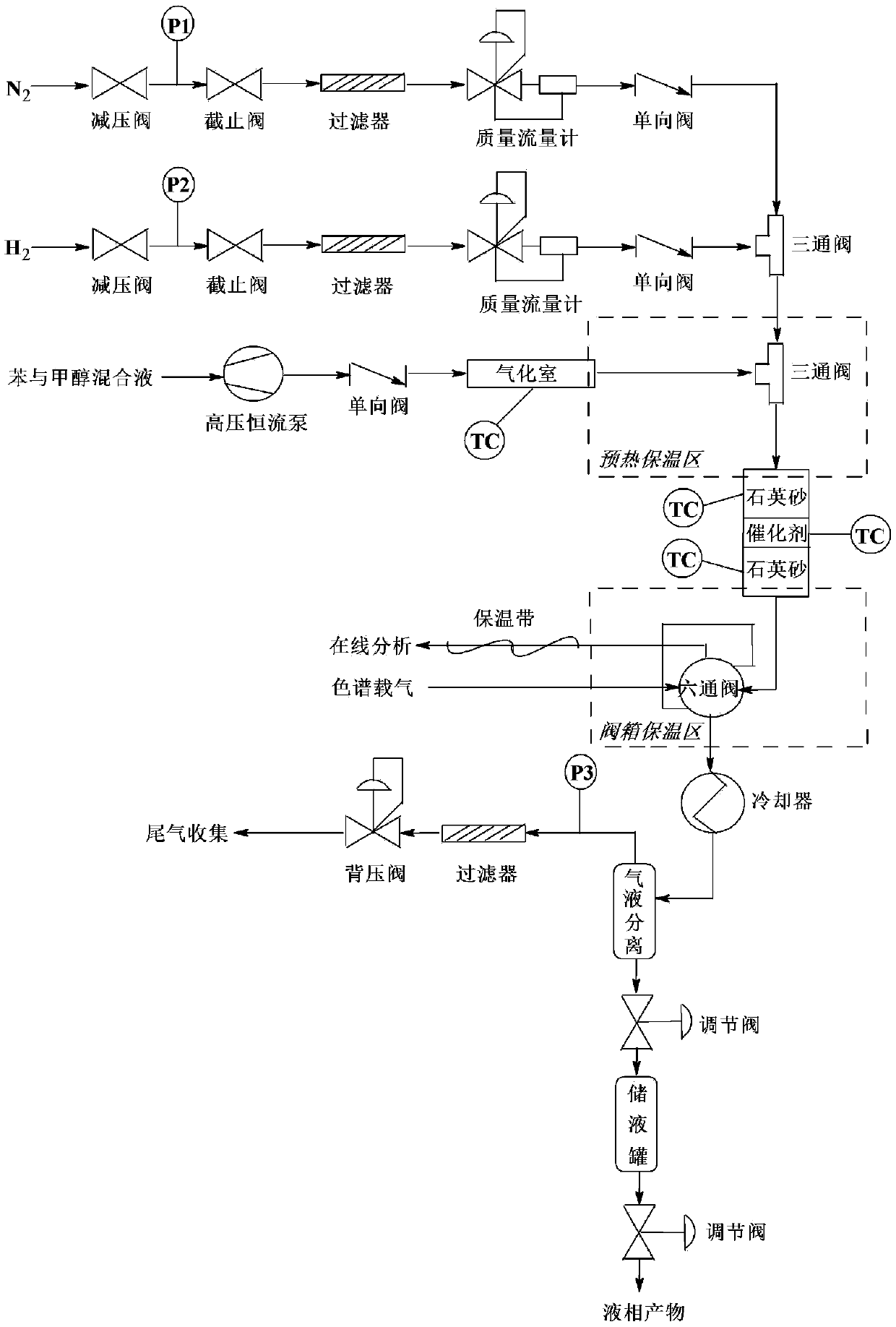

[0023] Catalyst evaluation reactions all use a fixed-bed reaction device, the inner diameter of the reaction tube is 8mm, and the reaction tube adopts a three-stage temperature control mode of upper, middle and lower. Evaluation devices (such as figure 1 shown) consists of two gas circuits and a liquid circuit, the gas circuits are respectively used to feed N 2 , where N 2 The function is to purge the reaction system to remove air, check the overall air tightness, and use it as a carrier gas to bring the gasified reaction raw materials into the reaction tube. The reaction solution first enters the gasification chamber through the high-pressure constant-flow pump for gasification, and then enters the reaction tube for reaction after mixing with the carrier gas in the preheating and heat preservation zone. The gas phase product after the reaction is directly analyzed by online gas chromatography through the six-way valve. In order to maintain the gas phase state of the product...

Embodiment 3

[0031] Change reactant, catalyst evaluation method is with reference to embodiment 2, and the results are shown in Table 2:

[0032] Table 2: Alkylation performance of toluene and methanol

[0033] catalyst

[0034] Note: toluene:methanol=2:1, reaction temperature 400°C, pressure 0.1MPa, WHSV=2h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com