Dust control system and method of underground coal-unloading ditch

A dust control and ground technology, applied in loading/unloading, conveyor, transportation and packaging, etc., can solve problems such as nozzle replacement, high water quality requirements, and canopy coal, and achieve the effect of reducing rust, engineering quantity and investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

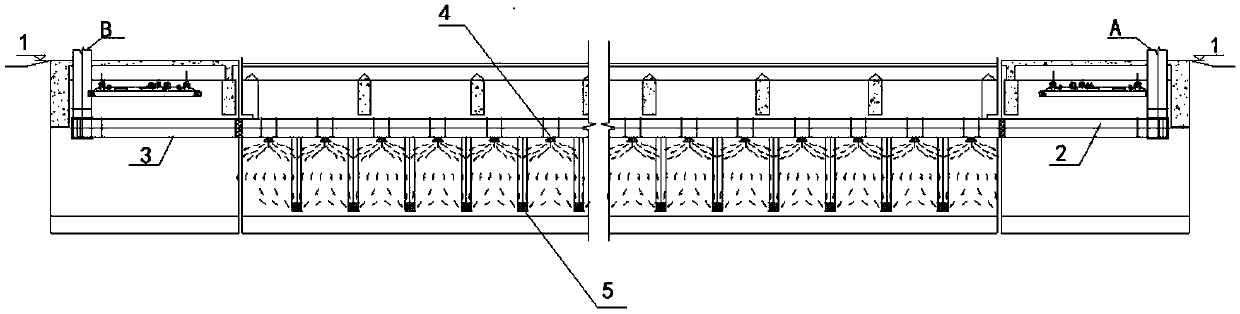

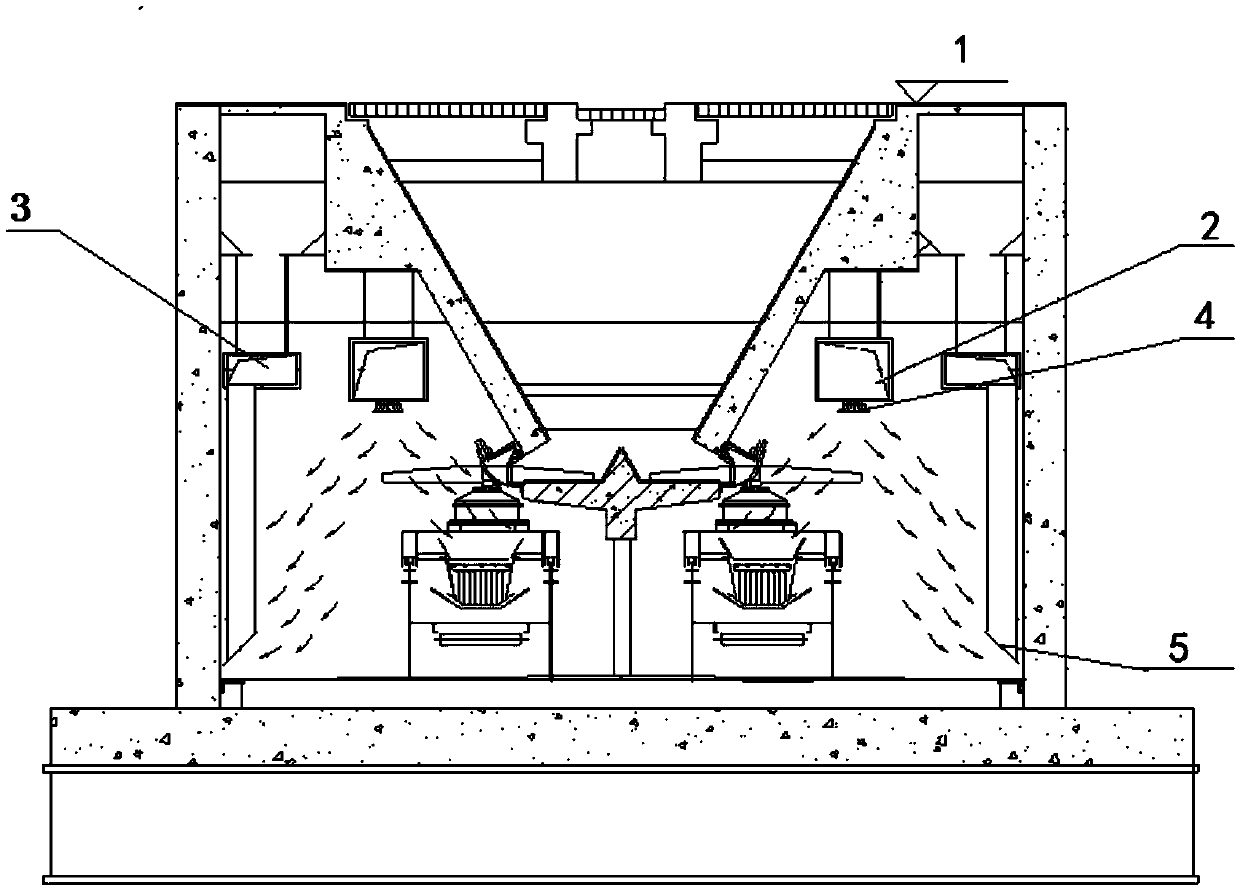

[0042] Such as figure 1 As shown, the fresh air is processed by the air supply box, and sent to the coal unloading ditch through the air supply vertical pipe and the air pipe arranged along the upper part of the coal unloading ditch. The air outlet 5 is evenly distributed on the lower side, forming an airflow that flows uniformly downward from the upper part in the whole process of the unloading ditch. No matter where the impeller coal feeder runs, the dust generated is pressed to the lower part for discharge, and the airflow is good. The organization ensures that the operating personnel in all areas of the coal unloading ditch are in clean air. The blower box and dust collector are conventional equipment, not shown separately.

[0043] The air intake (that is, air supply) and exhaust air enter from both ends of the coal unloading ditch, and the air flowing out of each air outlet has the same process from the air inlet equipment to the exhaust equipment. Therefore, relying on...

Embodiment 2

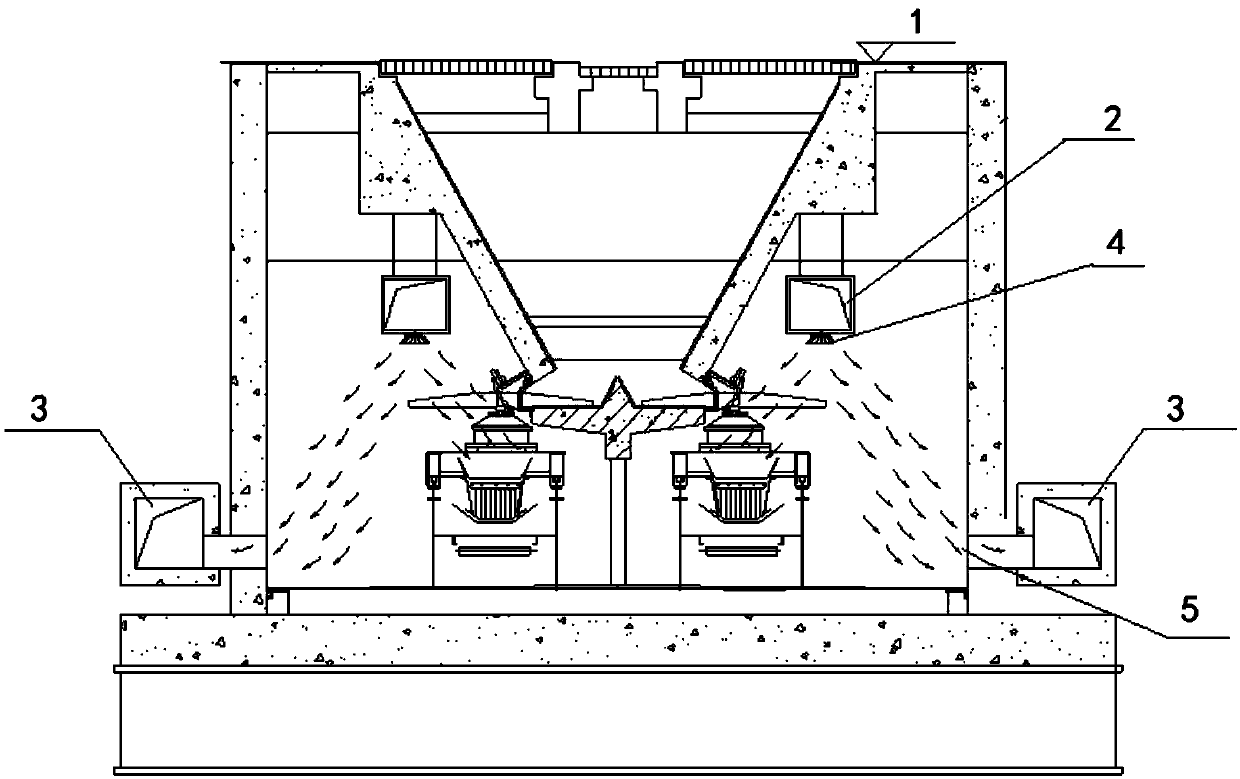

[0046] Such as image 3 As shown, in this embodiment, the air supply pipe and the air supply outlet are arranged above the coal unloading ditch, and the air exhaust outlet is arranged below the coal unloading ditch. The exhaust pipe is arranged below, on the outside of the wall of the coal unloading ditch. This arrangement of the return air system saves the vertical branch pipe of the return air, and also saves the space of the channel in the coal unloading ditch. The airflow organization and dust control effect are the same as in Example 1.

[0047] The supply and exhaust duct material can be metal, plastic, fiberglass, composite material or concrete, etc.

[0048] The air supply box and the dust removal equipment for the return air are all arranged on the ground, and the air supply box can use ordinary non-explosion-proof equipment to meet the requirements, which reduces the engineering volume and investment of underground construction, and at the same time reduces the cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com