Functional masterbatch for increasing oil filtration performance and preparation method of functional masterbatch

A functional masterbatch, oil filtration technology, applied in the field of plastic products, can solve the problems of limited filtration accuracy, increased breathing resistance, user discomfort, etc., to achieve environmental toxicity and side effects, good blocking effect, excellent oil resistance and water repellency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

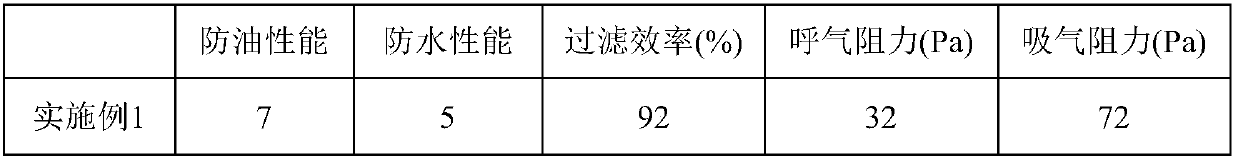

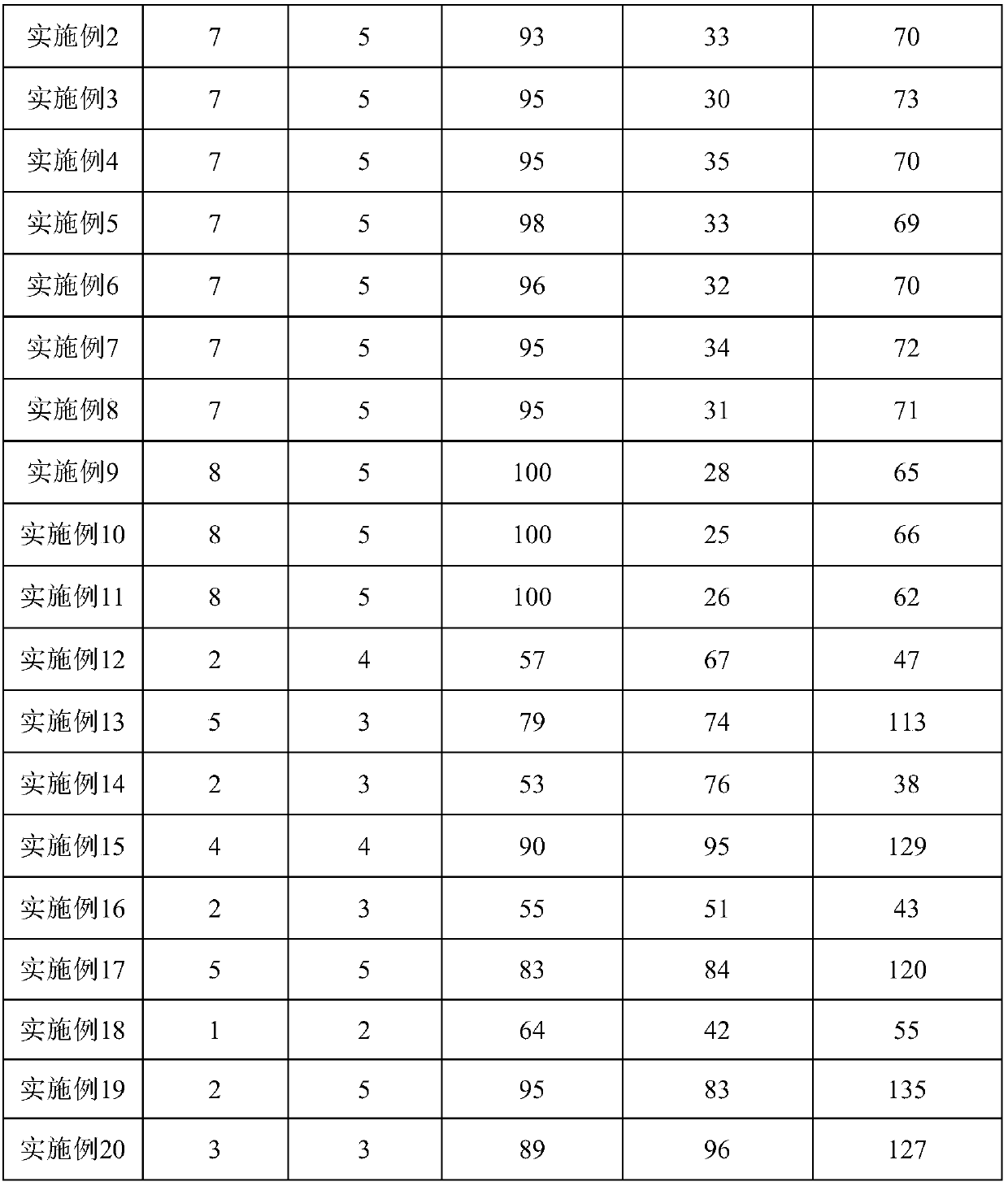

Examples

Embodiment 1

[0084]Embodiment 1 provides a functional masterbatch for increasing oil filtration performance, which includes the following components in parts by weight: 70 parts of polypropylene resin, 10 parts of lubricant, 0.2 part of release agent, 0.2 part of antioxidant, carbonic acid 1 part calcium, 5 parts polyacrylate, 1 part ionomer.

[0085] The polypropylene resin is a product purchased from ExxonMobil with the trade number 6936G2.

[0086] Described lubricant is magnesium stearate.

[0087] The antioxidant is obtained by compounding antioxidant 1010 and antioxidant 168 in a weight ratio of 1:1.

[0088] The calcium carbonate was purchased from Qingyuan Gaofeng Powder Co., Ltd., and the brand was GF2000.

[0089] The raw materials for the preparation of the polyacrylate include fluorine-containing acrylate and alkyl methacrylate.

[0090] The alkyl methacrylate is synthesized by direct esterification of alkyl alcohol and methacrylic acid, and the preparation steps include:

...

Embodiment 2

[0103] Embodiment 2 provides a functional masterbatch for increasing the oil filtration performance, comprising the following components in parts by weight: 90 parts of polypropylene resin, 20 parts of lubricant, 0.5 part of release agent, 1 part of antioxidant, carbonic acid Calcium 2 parts, polyacrylate 10 parts, ionomer 2 parts.

[0104] The polypropylene resin is a product purchased from Yanshan Petrochemical Co., Ltd. with the brand name of 1500P.

[0105] Described lubricant is magnesium stearate.

[0106] The antioxidant is obtained by compounding antioxidant 1010 and antioxidant 168 in a weight ratio of 1:1.

[0107] The calcium carbonate was purchased from Qingyuan Gaofeng Powder Co., Ltd., and the brand was GF2000.

[0108] The polyacrylate is the same as in Example 1, except that the monomer alkyl alcohol is myristyl alcohol.

[0109] Described ionic polymer is sodium ion polymer, purchased from U.S. DuPont, the trade mark is 1702 product.

[0110] The prepara...

Embodiment 3

[0112] Embodiment 3 provides a functional masterbatch for increasing oil filtration performance, comprising the following components in parts by weight: 75 parts of polypropylene resin, 12 parts of lubricant, 0.3 part of release agent, 0.3 part of antioxidant, carbonic acid Calcium 1.2 parts, polyacrylate 6 parts, ionomer 1.2 parts.

[0113] The polypropylene resin is purchased from LyondellBasell under the brand name HF568X.

[0114] Described lubricant is magnesium stearate.

[0115] The antioxidant is obtained by compounding antioxidant 1010 and antioxidant 168 in a weight ratio of 1:1.

[0116] The calcium carbonate was purchased from Qingyuan Gaofeng Powder Co., Ltd., and the brand was GF2000.

[0117] The polyacrylate is the same as in Example 1, except that the monomer alkyl alcohol is cetyl alcohol.

[0118] Described ionic polymer is sodium ion polymer, purchased from U.S. DuPont, the trade mark is 1702 product.

[0119] The preparation method of the functional ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com