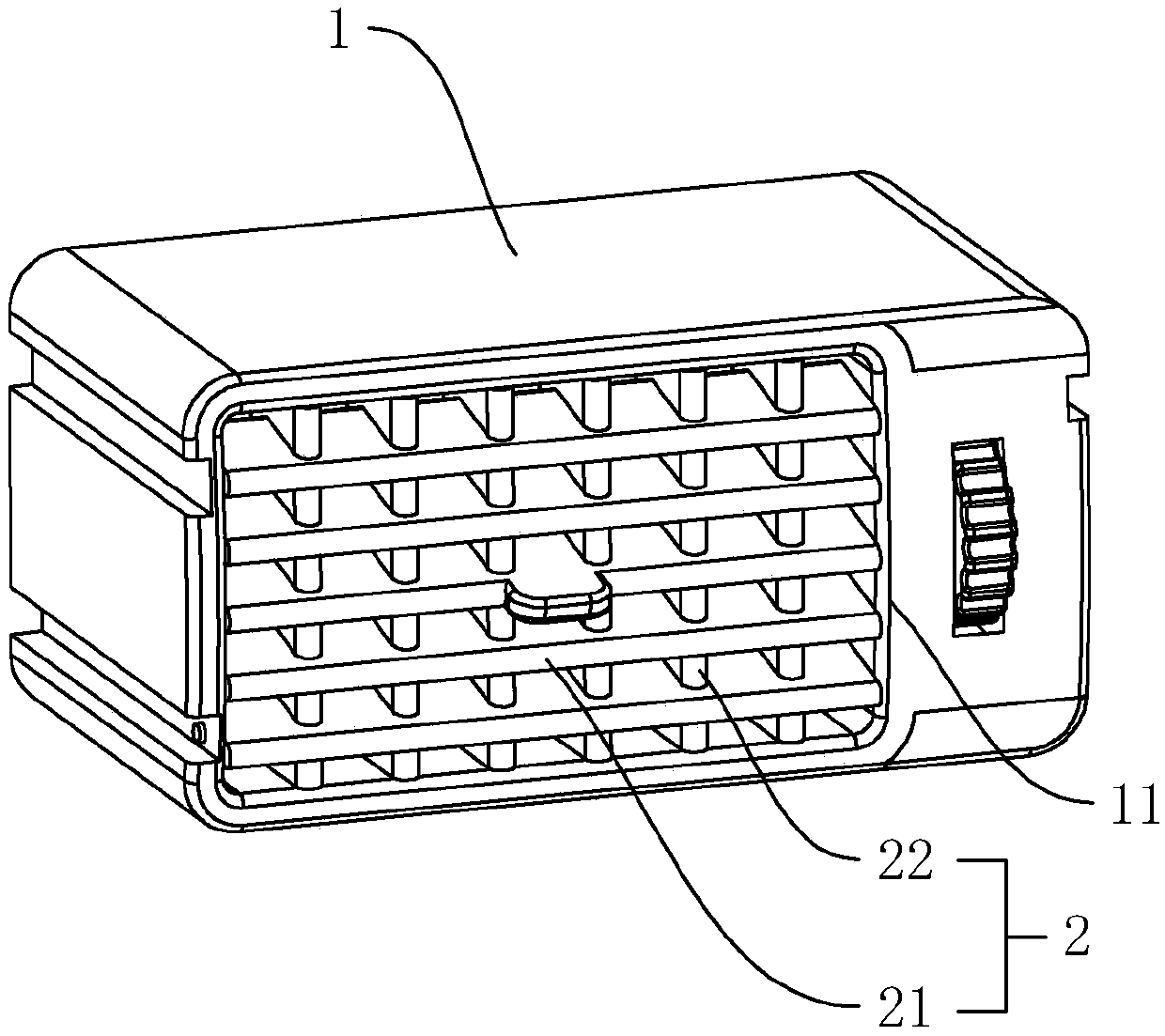

High-strength air conditioning air outlet assembly

A high-strength air outlet technology, applied in air handling equipment, heating/cooling equipment, transportation and packaging, etc., can solve the problems of reduced strength of plastic materials, increased brittleness of plastic materials, and easy damage of air-conditioning outlet assemblies. Achieve the effects of improving strength, reducing water absorption, and reducing VOC volatilization and dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

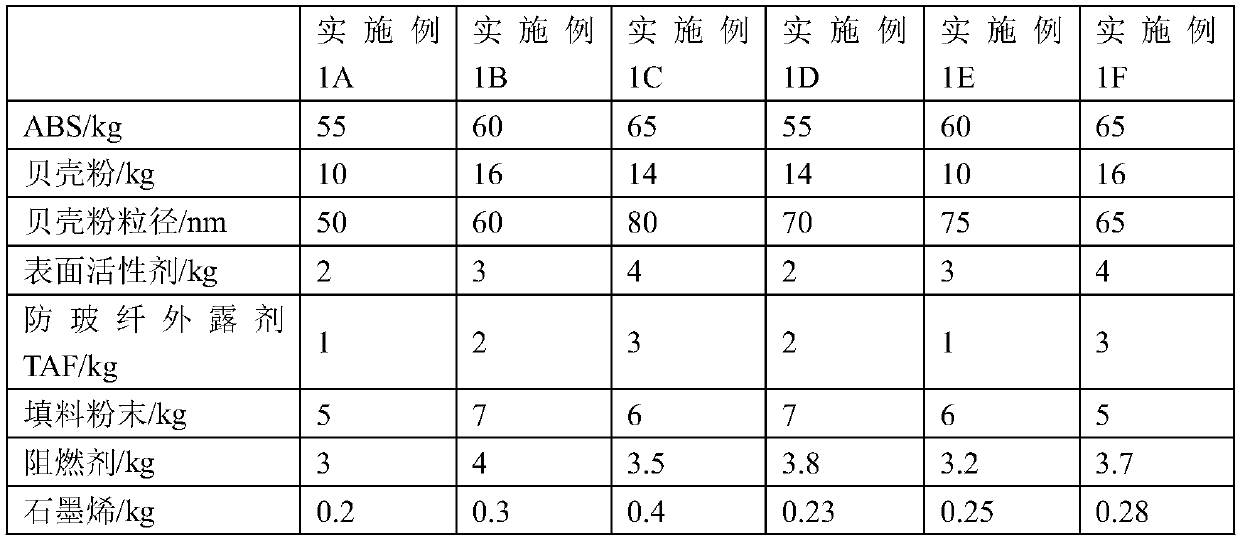

Embodiment 1

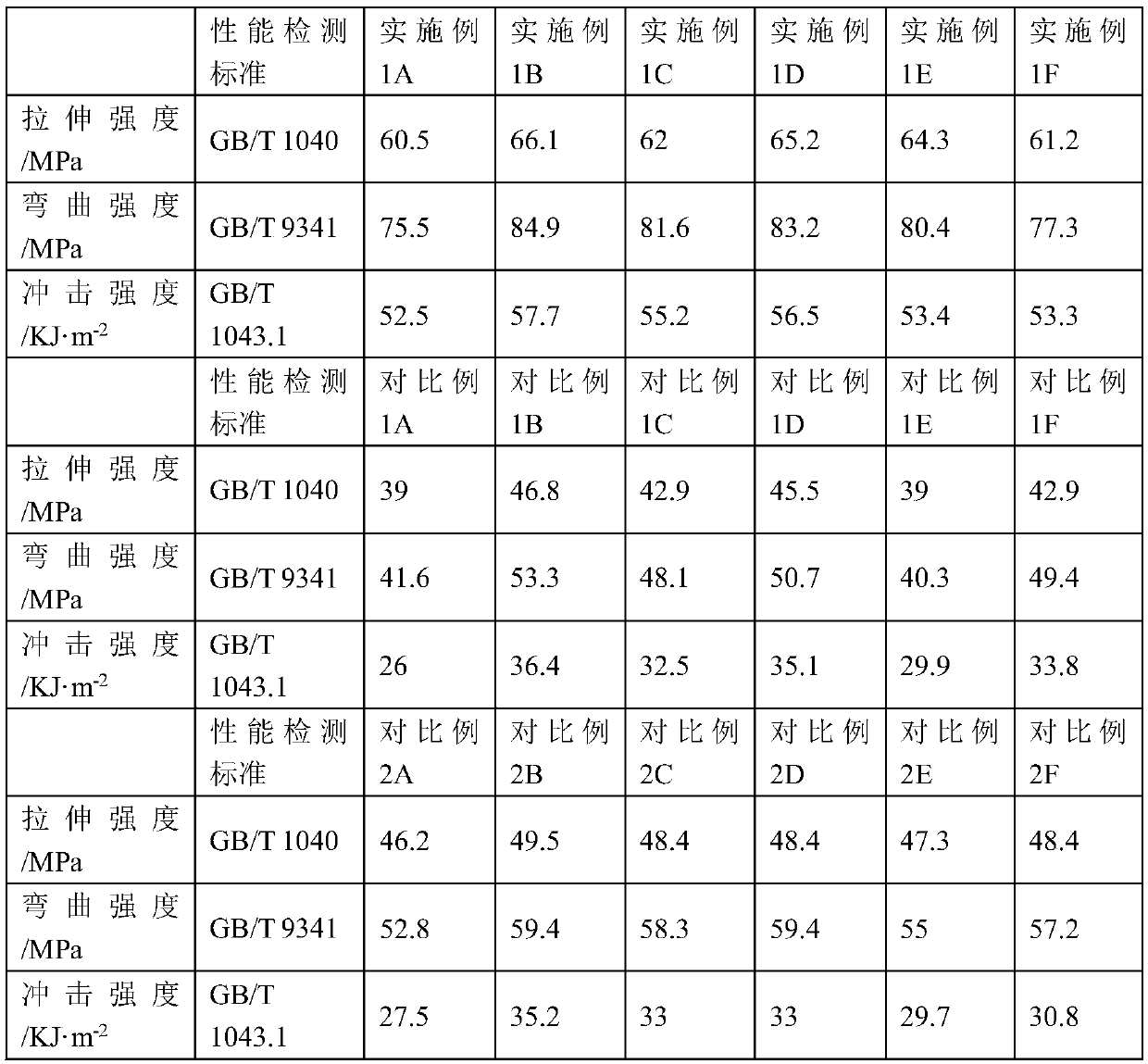

[0047] The raw materials of the modified ABS material include the following components in parts by mass: 55-65 parts of ABS, 10-16 parts of shell powder, 2-4 parts of surfactant, 1-3 parts of anti-glass fiber exposure agent TAF, 5- 7 powder, 3-4 parts of flame retardant and 0.2-0.4 parts of graphene. Among them, ABS is a commercially available product, and LG Chem HF-380, HF-381 brand products and Yongxing HI-140, HI-130, HI-121H brand products are selected. Shell powder is a commercially available product with a particle size of 80nm. Sodium dodecylbenzene sulfonate or sodium lignin sulfonate is used as the surfactant, and grinding wheel ash is used as the filler powder, which is a commercially available product at Qinghe Renewable Resources Recycling Station, Pingshan New District, Shenzhen. The flame retardant is DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide), which is a commercially available product. Graphene is a commercially available product from Beijing D...

Embodiment 2

[0073] An air-conditioning air outlet assembly, based on the basis of Example 1, the difference is that the raw material flame retardant of the modified ABS material is ODOPB, that is, 10-(2,5-dihydroxyphenyl)-10-hydrogen- 9-oxa-10-phosphaphenanthrene-10-oxide, the amount of flame retardant is the same as the amount of a flame retardant in the embodiment, and the other ingredients in the specific raw material amount are the same as in the first embodiment, based on the modification of the first embodiment The preparation method of the ABS material is to prepare the modified ABS material to obtain the examples 2A-2F corresponding to the examples 1A-1F.

[0074] For the modified ABS materials obtained in Examples 1A-1F and Examples 2A-2F, samples were prepared according to the detection method recorded in the flammability UL94 grade standard and the flame retardancy level of the modified ABS materials was tested. The test results are as follows.

[0075]

[0076] According to...

Embodiment 3

[0082] An air-conditioning air outlet assembly, based on the first embodiment, the difference is that the raw material of the modified ABS material also includes a graphene dosage of 0, and the other components in the specific raw material dosage are the same as the first embodiment. Based on the preparation method of the modified ABS material in Example 1, Examples 3A-3F corresponding to Examples 1A-1F are obtained.

[0083] The modified ABS material obtained in Examples 3A-3F was subjected to a water absorption test, a mechanical property test and a mechanical property test after the water absorption test, and the test results were as follows.

[0084] (1) Water absorption test.

[0085]

[0086] (2) Mechanical property test.

[0087] Test environment temperature: 25°C, tensile speed: 50mm / min; bending test speed: 2mm / min.

[0088]

[0089] (2) Mechanical property test after water absorption.

[0090] Test environment temperature: 25°C, tensile speed: 50mm / min; bend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com