High-flux material synthesis and synchronous radiation light source high-flux representing method of composite material chip

A technology of combining material chips and synthesis methods, which is applied in the fields of analyzing materials, material analysis using wave/particle radiation, and measuring devices, etc., can solve problems such as wasting time, and achieve the effect of saving sample production time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1.(Lu 1-x Sc x ) 0.99 Ce 0.01 BO 3 Sample combination material chip production

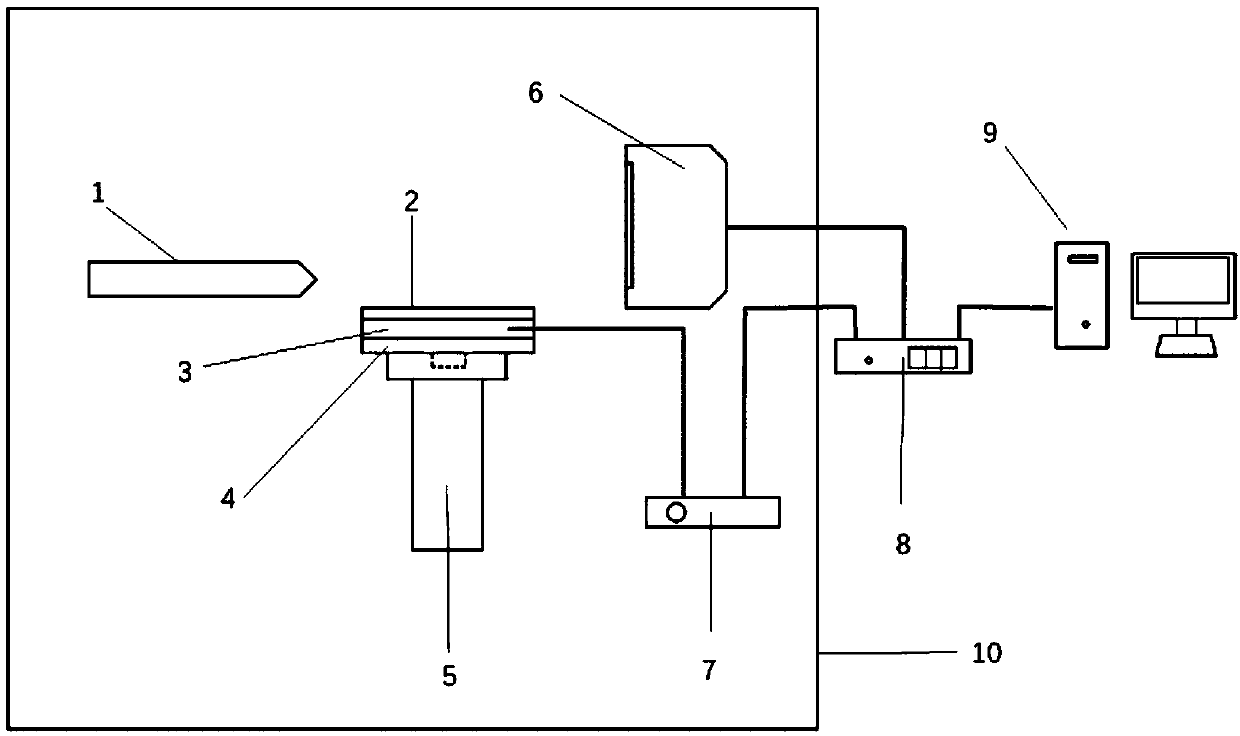

[0037] In this embodiment, referring to Figures 3 and 7, a high-throughput material synthesis method based on a combined material chip can prepare materials with a multi-component concentration gradient at one time, and the addition amount of each component material can be accurate Control ≤±1μL, prepare precursor by chemical method, and conduct high temperature heat treatment, the steps are as follows:

[0038] a. Raw material preparation: use Lu(NO) with a concentration of 1mol / L 3 ) 3 , Sc(NO 3 ) 3 , Ce(NO 3 ) 3 And the concentration of 0.9mol / L H 3 BO 3 As the sample raw material standard solution, citric acid with a concentration of 1mol / L is used as the complexing agent;

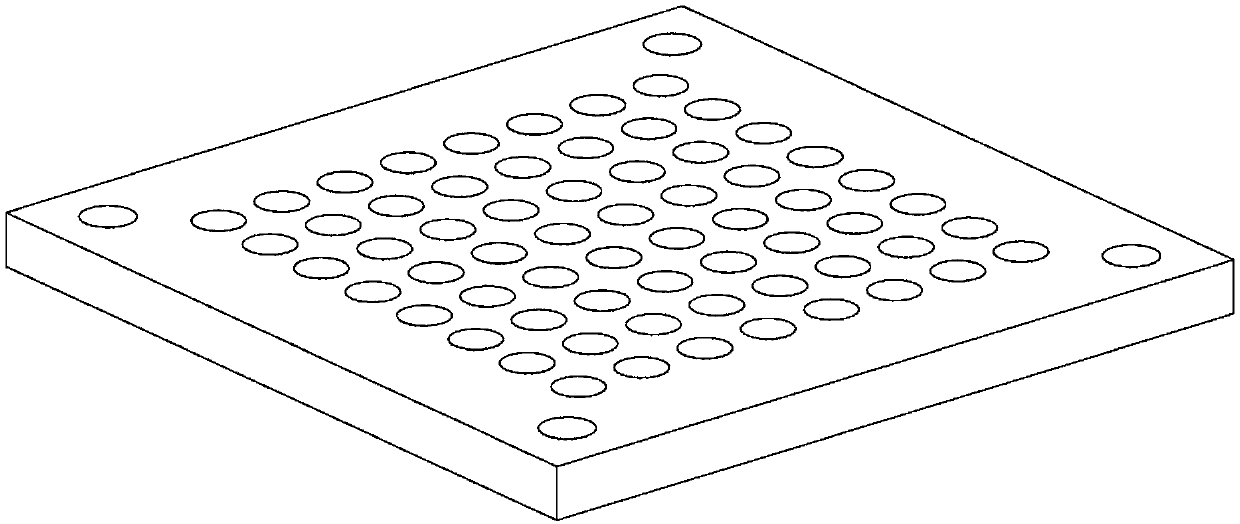

[0039] b. Add the above-mentioned standard solution to different storage tanks of the raw material bin of the combined material instrument. Use a porous quartz substrate with 50 reaction chambers as the reaction container....

Embodiment 2

[0056] This embodiment is basically the same as the first embodiment, and the special features are:

[0057] 1.(Lu 1-x Y x ) 0.99 Ce 0.01 BO 3 Sample combination material chip production

[0058] In this embodiment, see Figure 4, Image 6 As shown in Figure 7, a high-throughput material synthesis method based on a combined material chip can prepare multi-component concentration gradient materials at one time, and the addition amount of each component material can be accurately controlled ≤±1μL, prepared by chemical methods Precursor, and high temperature heat treatment, the steps are as follows:

[0059] a. Raw material preparation: use Lu(NO) with a concentration of 1mol / L 3 ) 3 , Y(NO 3 ) 3 , Ce(NO 3 ) 3 And the concentration of 0.9mol / L H 3 BO 3 As the sample raw material standard solution, citric acid with a concentration of 1mol / L is used as the complexing agent;

[0060] b. Add the above-mentioned standard solution to different storage tanks of the raw material bin of the combin...

Embodiment 3

[0074] This embodiment is basically the same as the previous embodiment, and the special features are:

[0075] 1.(Lu 0.8 Sc 0.2 ) 1-x Ce x BO 3 Sample combination material chip production

[0076] In this embodiment, see Figure 4, Image 6 As shown in Figure 7, a high-throughput material synthesis method based on a combined material chip can prepare multi-component concentration gradient materials at one time, and the addition amount of each component material can be accurately controlled ≤±1μL, prepared by chemical methods Precursor, and high temperature heat treatment, the steps are as follows:

[0077] a. Raw material preparation: use Lu(NO) with a concentration of 1mol / L 3 ) 3 , Sc(NO 3 ) 3 , Ce(NO 3 ) 3 And the concentration of 0.9mol / L H 3 BO 3 As the sample raw material standard solution, citric acid with a concentration of 1mol / L is used as the complexing agent;

[0078] b. Add the above standard solutions to the different storage tanks of the raw material bin of the combined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com