Water-based asymmetric super capacitor based on NiCo-LDH/rGO and rGO and preparation method thereof

A supercapacitor, asymmetric technology, used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve problems such as capacitance attenuation, and achieve the effect of improving conductivity, increasing specific capacity, and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

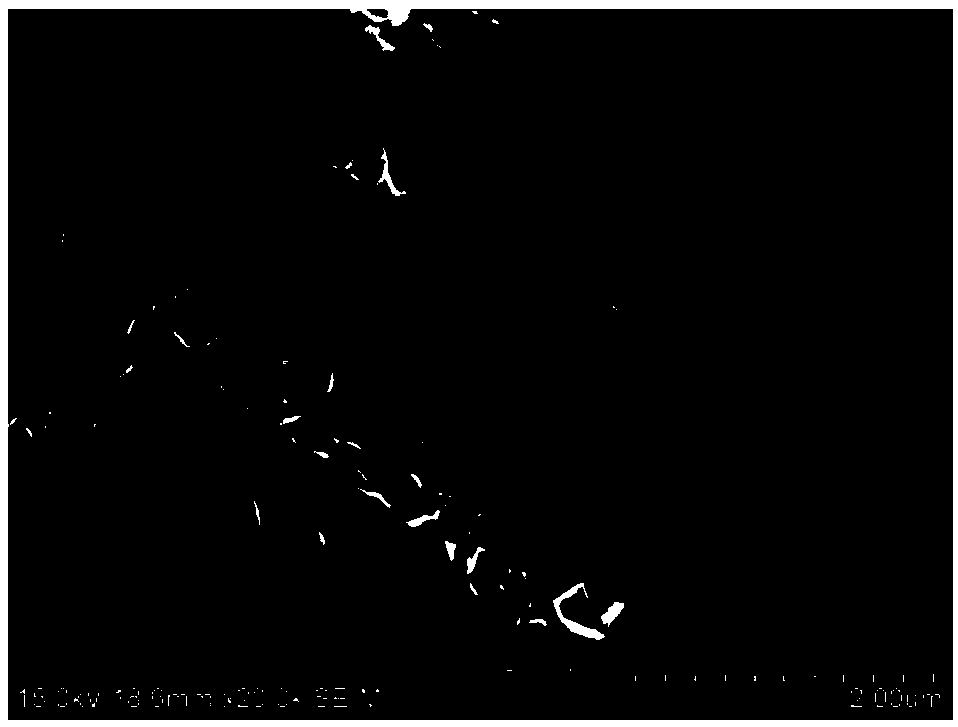

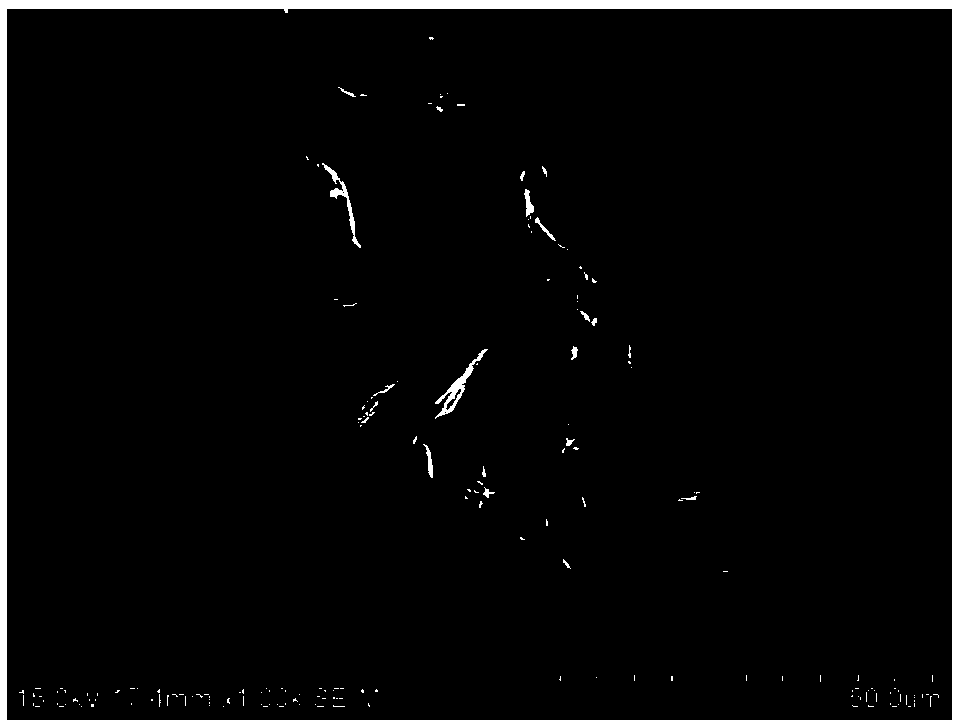

[0060] (1) Preparation and characterization of NiCo-LDH / rGO composite material: ultrasonically disperse 20 mg graphene oxide in 40 mL methanol solution, dissolve 0.5 mmol cobalt nitrate and 1.0 mmol nickel nitrate in the above solution, stir for 30 minutes, and dissolve The solution was transferred to a 100mL polytetrafluoroethylene reactor and reacted at 180°C for 12h. After the reaction, cool to room temperature, collect the product by centrifugation, and vacuum-dry at 60°C to obtain a NiCo-LDH / rGO composite material. Its structure is as figure 1 , 2 shown. in figure 1 is a high-magnification scanning electron microscope image, figure 2 It is a transmission electron microscope image, as shown in the figure, the sheet-like NiCo-LDH grows vertically on the graphene surface to form a layered structure.

[0061] (2) Preparation and characterization of rGO: Using graphene oxide and urea as raw materials and methanol as a solvent, 20 mg of graphene oxide was ultrasonically d...

Embodiment 2

[0068] (1) Preparation of NiCo-LDH / rGO composites:

[0069] Ultrasonic disperse 20 mg of graphene oxide in 40 mL of methanol solution, dissolve 1.0 mmol of cobalt nitrate and 0.5 mmol of nickel nitrate in the above solution, stir for 30 minutes, transfer the solution to a 100 mL polytetrafluoroethylene reactor, and heat at 180 ° C Reaction 12h. After the reaction, cool to room temperature, collect the product by centrifugation, and vacuum-dry at 60°C to obtain a NiCo-LDH / rGO composite material.

[0070] (2) Preparation of rGO:

[0071] Using graphene oxide and urea as raw materials and methanol as solvent, ultrasonically disperse 20mg of graphene oxide in 40mL of methanol solution, transfer the solution to a 100mL polytetrafluoroethylene reactor, and react at 180°C for 12h. After the reaction, the product was cooled to room temperature, centrifuged to collect the product, and dried under vacuum at 60°C to obtain rGO.

[0072] (3) Preparation and performance characterization...

Embodiment 3

[0081] (1) Preparation of NiCo-LDH / rGO composites:

[0082] Ultrasonic disperse 20mg of graphene oxide in 40mL of methanol solution, dissolve 0.75mmol of cobalt nitrate and nickel nitrate in the above solution, stir for 30 minutes, transfer the solution to a 100mL polytetrafluoroethylene reactor, and react at 180°C for 12h . After the reaction, cool to room temperature, collect the product by centrifugation, and vacuum-dry at 60°C to obtain a NiCo-LDH / rGO composite material.

[0083] (2) Preparation of rGO:

[0084] Using graphene oxide and urea as raw materials and methanol as solvent, ultrasonically disperse 20mg of graphene oxide in 40mL of methanol solution, transfer the solution to a 100mL polytetrafluoroethylene reactor, and react at 180°C for 12h. After the reaction, the product was cooled to room temperature, centrifuged to collect the product, and dried under vacuum at 60°C to obtain rGO.

[0085] (3) Preparation and performance characterization of NiCo-LDH / rGO com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com