PWM heating control system and method

A heating control and heating control circuit technology, applied in control/regulation systems, ohmic resistance heating, electric heating devices, etc., can solve problems such as power consumption, waste, errors, etc., and achieve strong anti-interference ability, simple structure, and accurate temperature control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

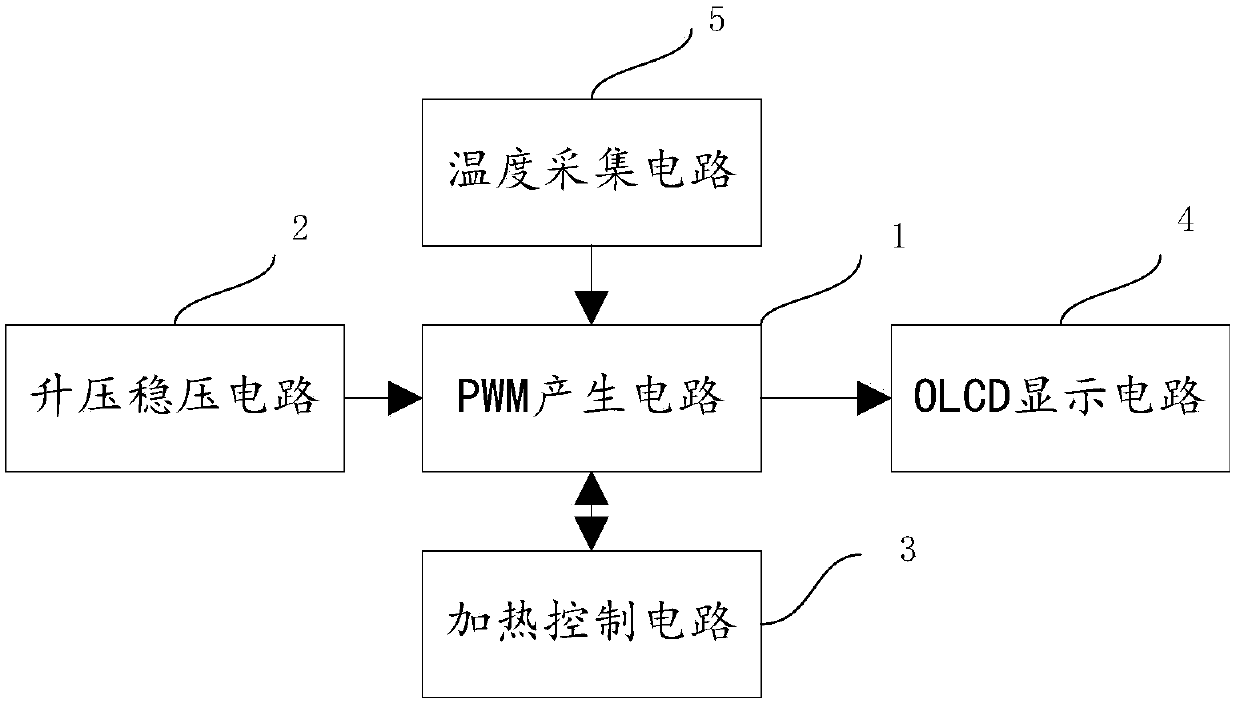

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings. The present invention provides a PWM heating control system, such as figure 1 As shown, the system is composed of a PWM generating circuit 1, a boost voltage stabilizing circuit 2, a heating control circuit 3, an OLED display circuit 4 and a temperature acquisition circuit 5;

[0030] The power output end of the boosting and stabilizing circuit 2 is connected to the power input end of the PWM generating circuit 1, and the first digital input and output end of the PWM generating circuit 1 is connected to the digital input and output end of the temperature acquisition circuit 5, The PWM wave generating end of the PWM generating circuit 1 is connected to the signal receiving end of the heating control circuit 3 , and the second digital input and output end of the PWM generating circuit 1 is connected to the input and output end of the OLED display circuit 4 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com