Self-driven solar blind ultraviolet detector with organic-inorganic composite structure and preparation method thereof

An ultraviolet detector and inorganic composite technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of self-driven photodetectors that are difficult to manufacture and realize, and achieve excellent detection performance and material cost. The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

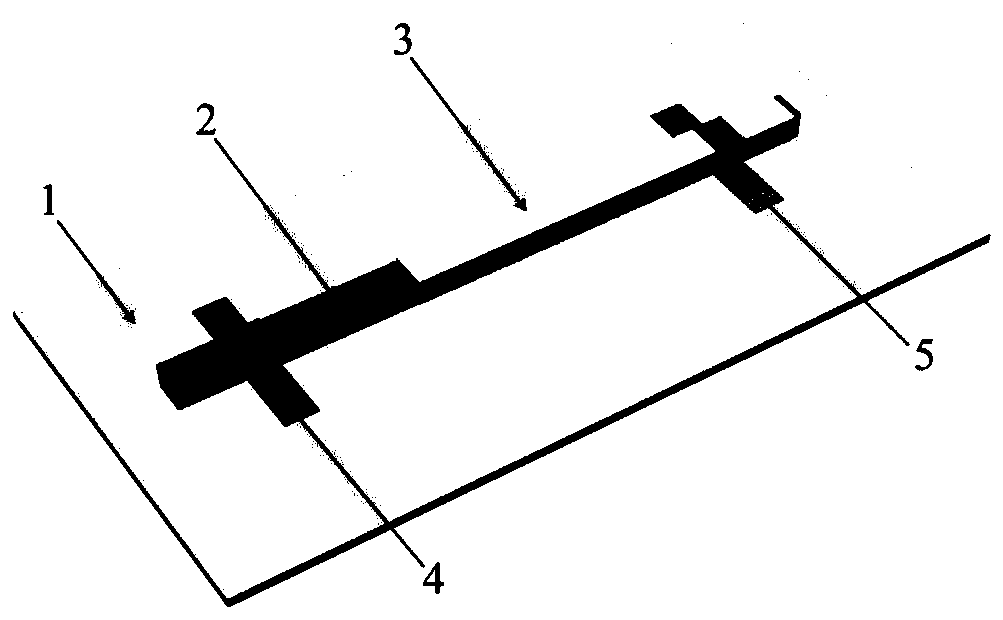

Image

Examples

Embodiment 1

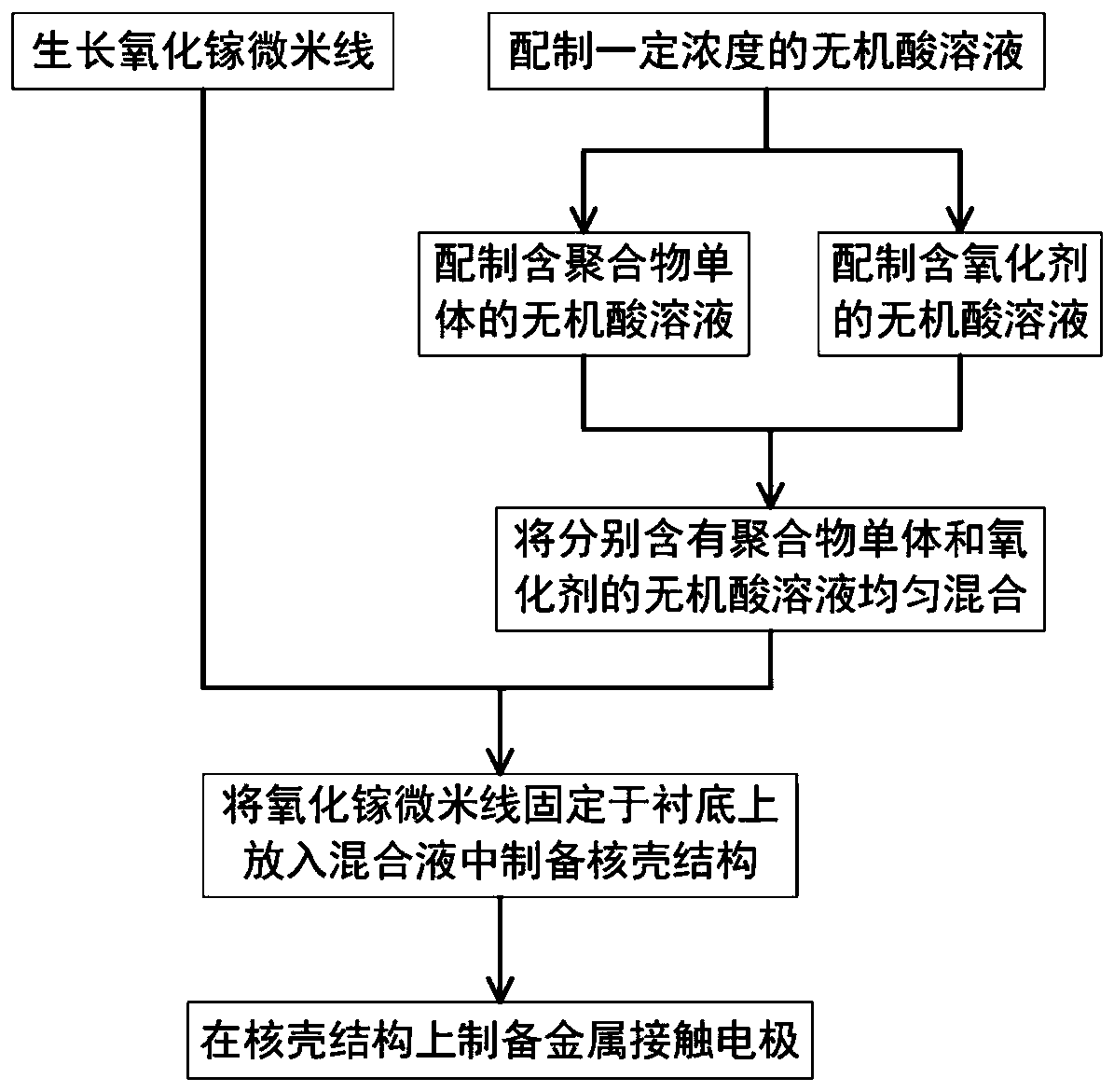

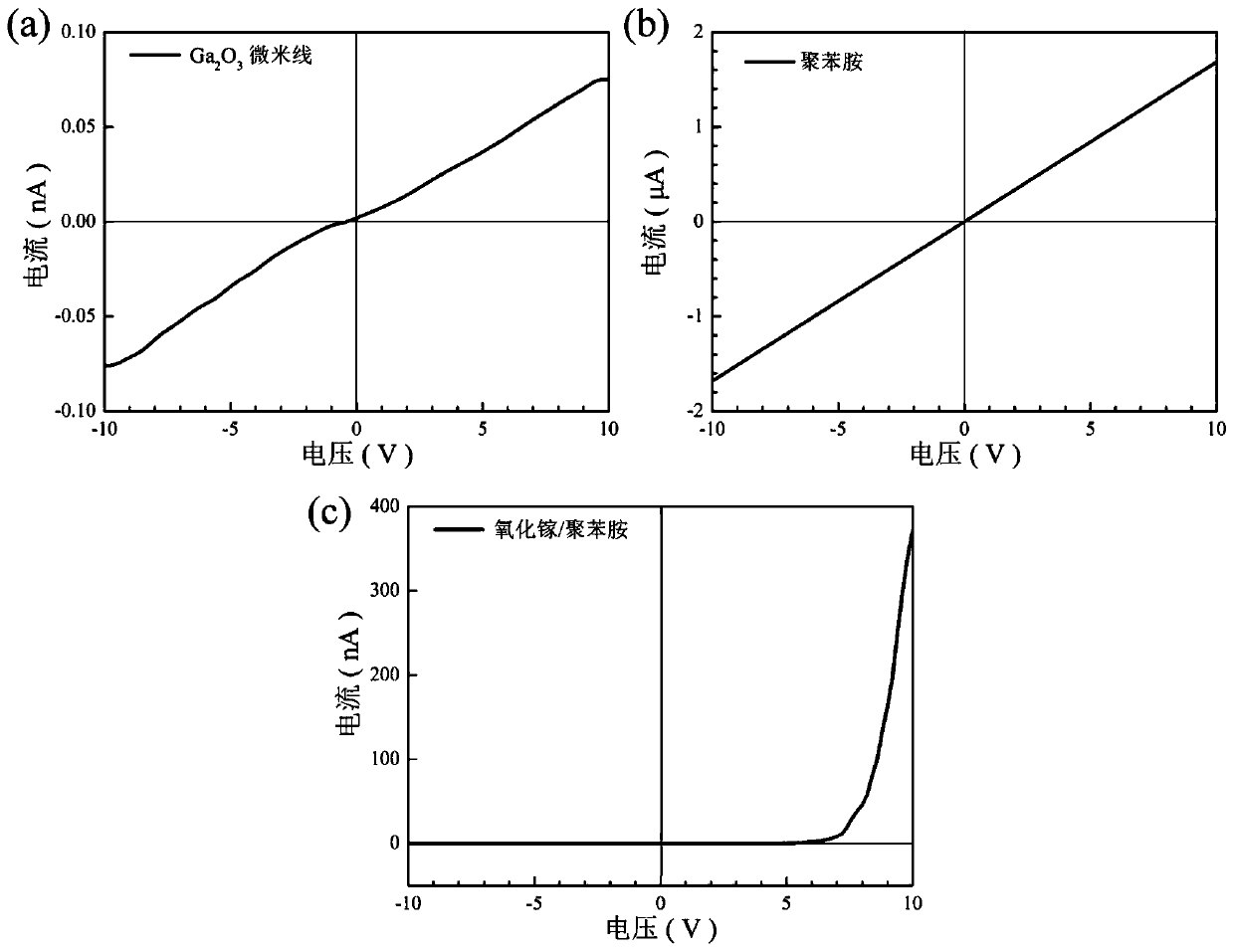

[0030] In this example, an organic-inorganic composite structure self-driven solar-blind ultraviolet detector is prepared according to the following steps:

[0031] Preparation of Microwires. Measure and mix high-purity gallium oxide powder and carbon powder with a mass ratio of 1:1, and grind for more than 2 hours. Put the above mixed powder into the middle of the corundum boat, place the substrate directly above the mixed powder, put the corundum boat into the quartz tube, and then put the quartz tube into the growth chamber of the horizontal high-temperature tube furnace for growth, and the growth environment is normal pressure , high-purity argon was introduced as a carrier gas during the growth process. After the growth is completed, the temperature is naturally lowered to obtain gallium oxide micron wires. The size of micron wires can be comprehensively regulated by growth temperature and growth time.

[0032] Preparation of reaction solution. First prepare a dilute ...

Embodiment 2

[0036] This example is the same as Example 1 except for the following features: Step 2) in this example measures 7.6 μL of pyrrole and dissolves it in dilute sulfuric acid solution.

Embodiment 3

[0038]This example is the same as Example 1 except for the following features: step 2) in this example measures 11.7 μL of 3,4-ethylenedioxythiophene and dissolves it in dilute sulfuric acid solution.

[0039] Under the condition that other conditions remain unchanged, the inorganic acid can also be HCl or HClO 4 , the oxidizing agent can also be K 2 Cr 2 o 7 、KIO 3 , FeCl 3 , FeCl 4 、H 2 o 2 , Ce(SO 4 ) 2 , MO 2 or BPOs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com