Ultraviolet detector with high wavelength selectivity and manufacturing method thereof

A technology of wavelength selectivity and manufacturing method, which is applied in the field of photoelectric detection, can solve the problems of inconvenient portability, high cost, and large equipment volume, and achieve the effect of simple structure, easy preparation, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

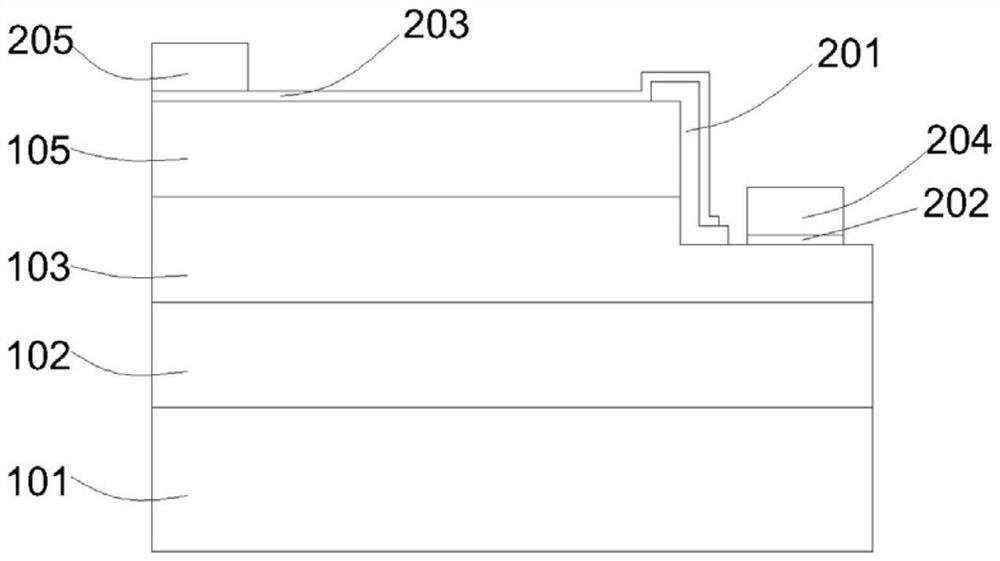

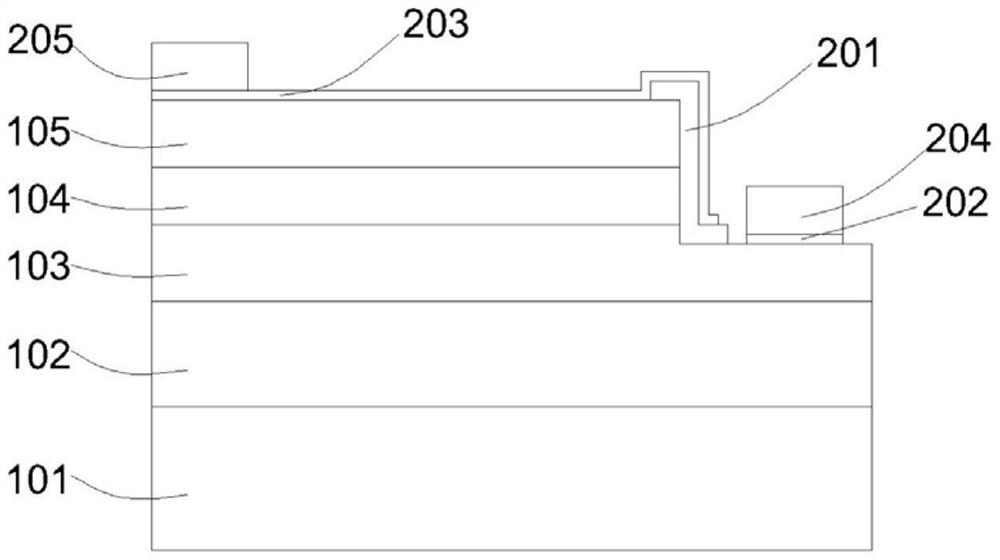

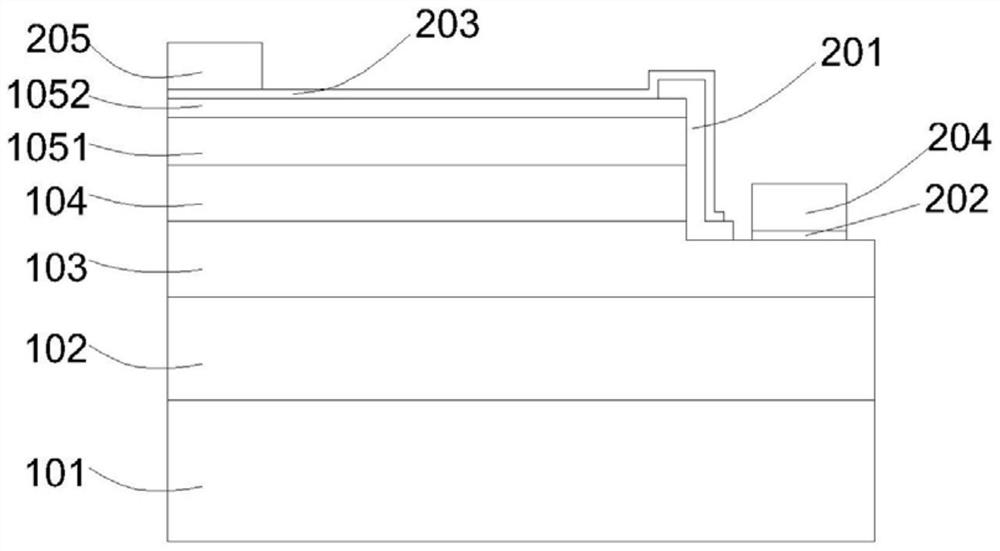

[0090] A method for fabricating a highly wavelength-selective ultraviolet detection device may comprise the steps of:

[0091] 1) GaN layer, n-GaN layer and p-GaN layer are sequentially stacked and grown on the substrate by metal organic compound chemical vapor deposition (MOCVD);

[0092] 2) Ultrasonic cleaning of the epitaxial structure obtained in step 1) with acetone, isopropanol, deionized water, etc., to remove organic impurities on the surface of the epitaxial structure, and using HCl immersion, deionized water ultrasonic treatment, etc., Remove the oxide layer on the surface of the epitaxial structure;

[0093] 3) Covering at least a partial area of the surface of the p-GaN layer with a patterned mask, and removing the p-GaN layer and part of the n-GaN layer not covered by the mask in the protection area by etching, so that the part The n-GaN layer is thinned, and the surface of the thinned n-GaN layer is exposed, thereby forming a step structure between the p-GaN l...

Embodiment 2

[0100] The fabrication method of the ultraviolet detection device with high wavelength selectivity in the present embodiment is basically the same as in the embodiment 1, the difference is that the Ag-Au alloy thin film in the present embodiment is Ag 0.7 Au 0.3 Thin film, after testing, the spectral responsivity peak of the ultraviolet detection device with high wavelength selectivity obtained in Example 2 is located at 380nm, and the full width at half maximum is 80nm.

Embodiment 3

[0102] The fabrication method of the ultraviolet detection device with high wavelength selectivity in the present embodiment is basically the same as in the embodiment 1, the difference is that the Ag-Au alloy thin film in the present embodiment is Ag 0.8 Au 0.2 Thin film, after testing, the spectral responsivity peak of the ultraviolet detection device with high wavelength selectivity obtained in Example 3 is located at 360nm, and the half maximum width is 55nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com