Oxygen evolution catalyst, preparation method thereof and anode for water electrolysis

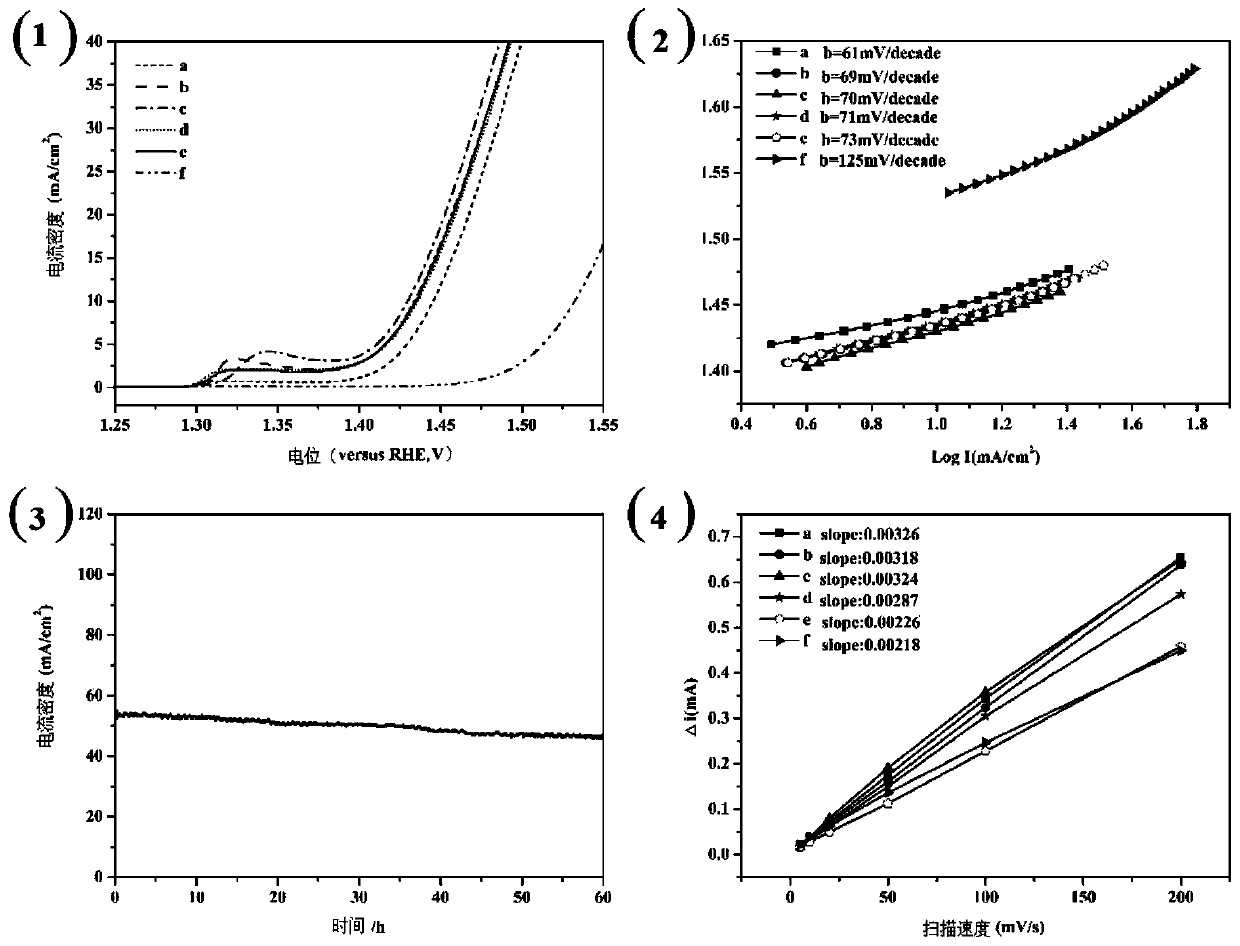

A catalyst and oxygen evolution technology, which is applied in the field of electrochemistry, can solve the problems of high cost and complicated preparation process, and achieve the effects of reducing preparation cost, simplifying the preparation process, and low oxygen evolution overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] On the one hand, an embodiment of the present invention provides a method for preparing an oxygen evolution catalyst, comprising the following steps:

[0020] S01: Provide nickel foam;

[0021] S02: placing the foamed nickel in a ferrous salt solution for mixing treatment, then adding a bicarbonate solution, and performing an in-situ co-precipitation reaction on the surface of the foamed nickel to obtain an oxygen evolution catalyst.

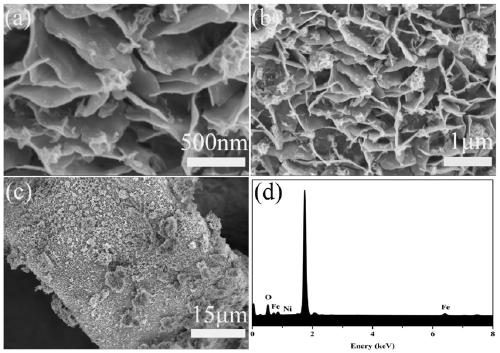

[0022] In the preparation method of the oxygen evolution catalyst provided by the embodiment of the present invention, the nickel foam is first placed in the ferrous salt solution so that the oxide layer on the surface of the nickel foam dissolves Ni in situ. 2+ , and then add bicarbonate solution to the preparation system, ionic HCO 3 - self ionizes CO 3 2- , so the self-ionized CO 3 2- than OH - The ion concentration is much larger, and in the liquid phase it first interacts with Fe 2+ Generate ferrous carbonate precipitates, th...

Embodiment 1

[0037] A kind of oxygen evolution catalyst, its preparation method comprises the steps:

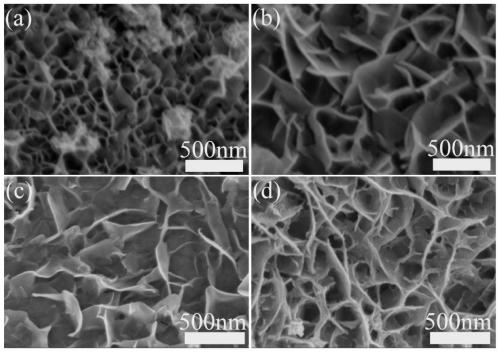

[0038] 3mmol FeSO 4 ·7H 2 O. A magnetic stirrer and untreated nickel foam are added together into a two-neck flask, and an inert gas is filled by vacuum displacement. Inject 20 ml of deionized water that has been bubbled with inert gas with a syringe, and stir at room temperature for 30 minutes. Then use a syringe to inject 2 mmol NH that has been bubbled with an inert gas 4 HCO 3 aqueous solution. Stir at room temperature for 24 hours after injection. Take out the nickel foam, rinse the surface with deionized water, and dry it in a blast oven at 60°C for 6 hours.

Embodiment 2

[0040] A kind of oxygen evolution catalyst, its preparation method comprises the steps:

[0041] 3mmol FeSO 4 ·7H 2 O. A magnetic stirrer and untreated nickel foam are added together into a two-neck flask, and an inert gas is filled by vacuum displacement. Inject 20 ml of deionized water that has been bubbled with an inert gas with a syringe, and stir at room temperature for 5 minutes. Then use a syringe to inject 2 mmol NH that has been bubbled with an inert gas 4 HCO 3 aqueous solution. Stir at room temperature for 24 hours after injection. Take out the nickel foam, rinse the surface with deionized water, and dry it in a blast oven at 60°C for 6 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com