Three-dimensional anode material and preparation method for hydrogen production by electrolysis of water

An anode material, a technology for electrolyzing water, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as being unsuitable for the controllable preparation of multi-component nanostructured oxygen evolution electrodes, achieve controllable structural components and improve utilization. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

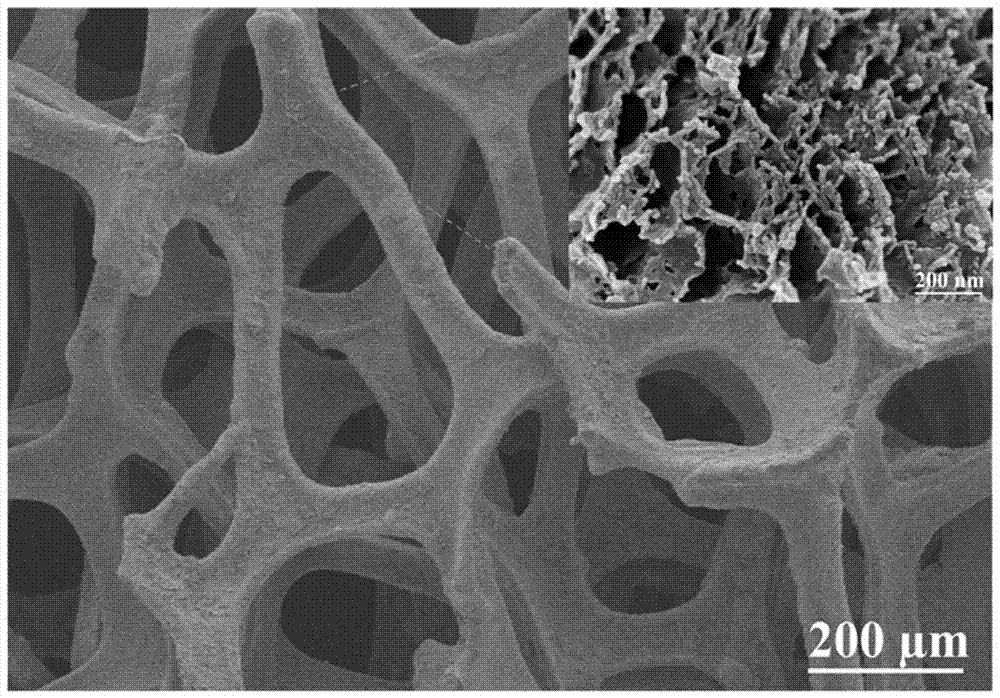

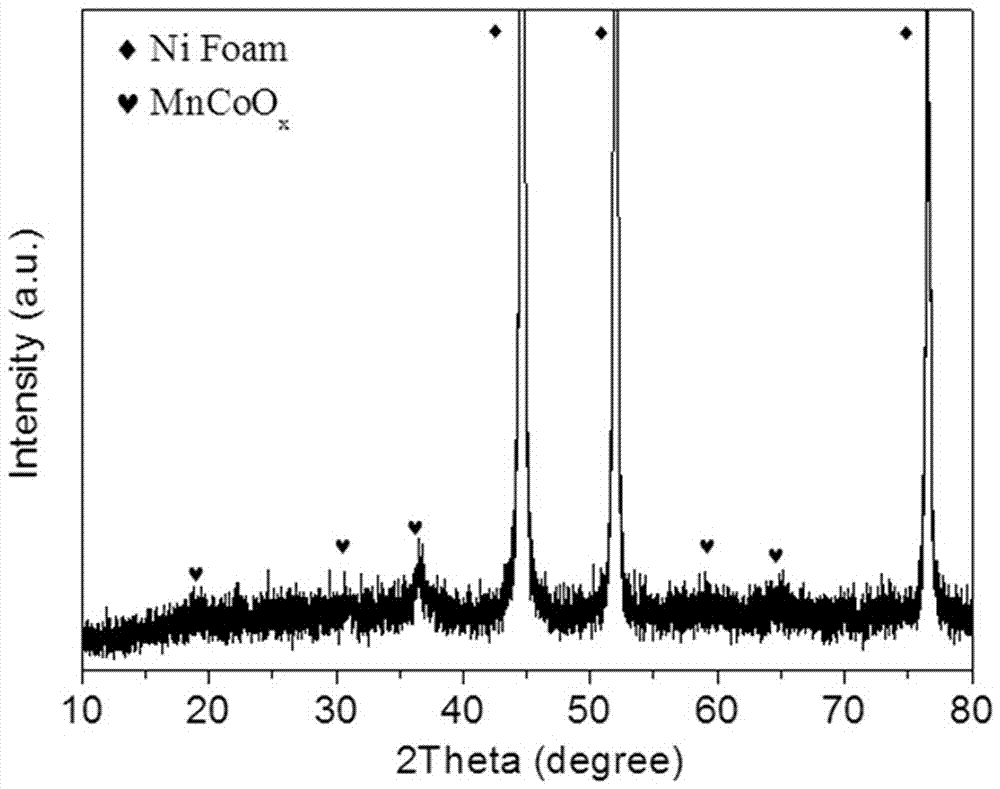

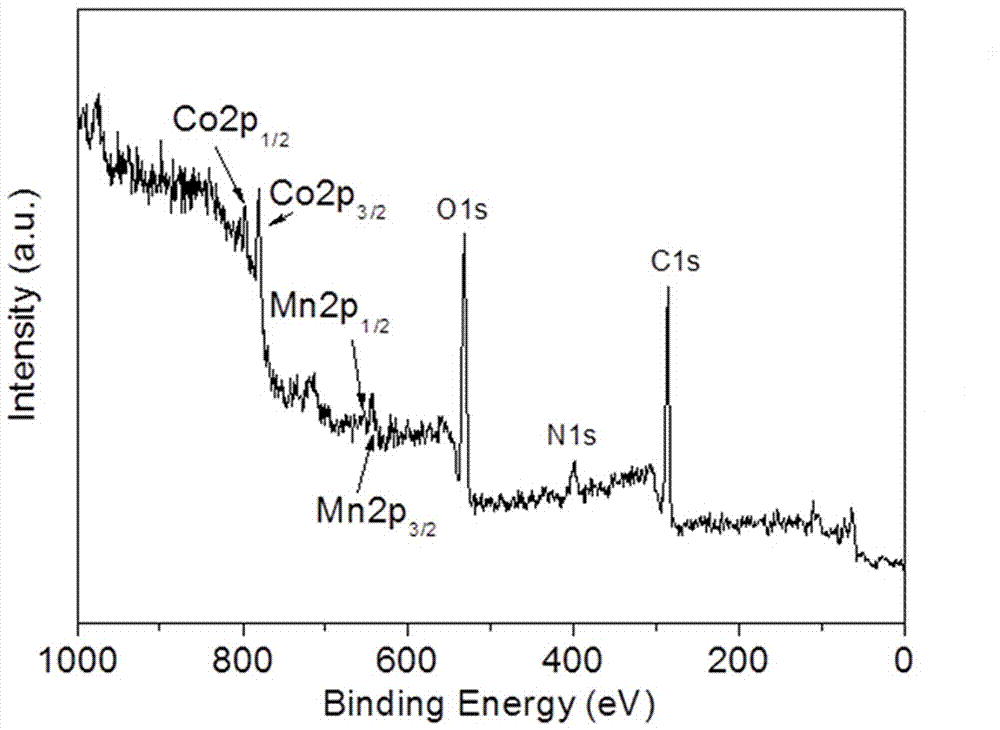

[0031] A new three-dimensional anode material for hydrogen production by electrolysis of water, including nitrogen-doped carbon / transition metal manganese-cobalt oxide supported on nickel foam and its three-dimensional anode sheet for hydrogen production by electrolysis of water, using a liquid-solid synthesis method In situ preparation, the specific steps are:

[0032] (1) Immerse the clean nickel foam sheet into 10mL of water and ethanol mixed solution containing manganese dichloride, cobalt chloride, citric acid, thiourea (molar ratio 1:2:2:1) (V 水 / V 醇 =1:3), take it out to dry at 75°C, and repeat three times;

[0033] (2) Calcinate the nickel foam sheet obtained in step 1 at 800°C for 6h under the protection of Ar gas at 50mL / min, and then at 200°C, O 2 Heating under the atmosphere for 1 h, cooling to room temperature to obtain a three-dimensional electrode of nitrogen-doped carbon / manganese-cobalt oxide supported on nickel foam.

[0034] The macroscopic comparison of ...

Embodiment 2

[0041] A new three-dimensional anode material for hydrogen production by electrolysis of water, including nitrogen-doped carbon / transition metal nickel-iron oxide supported by nickel foam and its three-dimensional anode sheet for hydrogen production by electrolysis of water, using a liquid-solid synthesis method In situ preparation, the specific steps are:

[0042] (1) Dip the clean foamed nickel sheet into 10mL of water and ethanol mixed solution (V 水 / V 醇 =1:1), take it out to dry at 75°C, and repeat three times;

[0043] (2) Calcinate the foamed nickel sheet obtained in step 1 at 700°C for 1 hour under the protection of Ar gas at 10mL / min, and then at 250°C, O 2 Heating under the atmosphere for 1.2h, cooling to room temperature to obtain a three-dimensional electrode of nitrogen-doped carbon / nickel-iron oxide supported on nickel foam.

Embodiment 3

[0045] A new three-dimensional anode material for hydrogen production by electrolysis of water, including nitrogen-doped carbon / transition metal cobalt-copper oxide supported on nickel foam and its three-dimensional anode sheet for hydrogen production by electrolysis of water, using a liquid-solid synthesis method In situ preparation, the specific steps are:

[0046] (1) Immerse the clean nickel foam sheet into 10mL of water and ethanol mixed solution (V 水 / V 醇 =1:9), take it out to dry at 75°C, and repeat three times;

[0047] (2) Calcinate the foamed nickel sheet obtained in step 1 at 600°C for 5h under the protection of 20mL / min Ar gas, and then at 220°C, O 2 Heating under the atmosphere for 1.5h, cooling to room temperature and then obtaining a three-dimensional electrode of nitrogen-doped carbon / cobalt-copper oxide supported on nickel foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com