Stainless steel super-hydrophobic and super-hydrophilic surface and preparation method and application thereof

A super-hydrophobic surface and super-hydrophilic technology, applied in welding equipment, manufacturing tools, laser welding equipment, etc., can solve problems such as limited condensation efficiency of condensation equipment, unstable quality of laser cladding, and condensate droplets detached from the surface, etc., to achieve Speed up condensation heat transfer efficiency, easy control of process parameters, and improve condensation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Embodiments of the present invention also provide a method for preparing a stainless steel superhydrophobic-superhydrophilic surface, comprising the following steps:

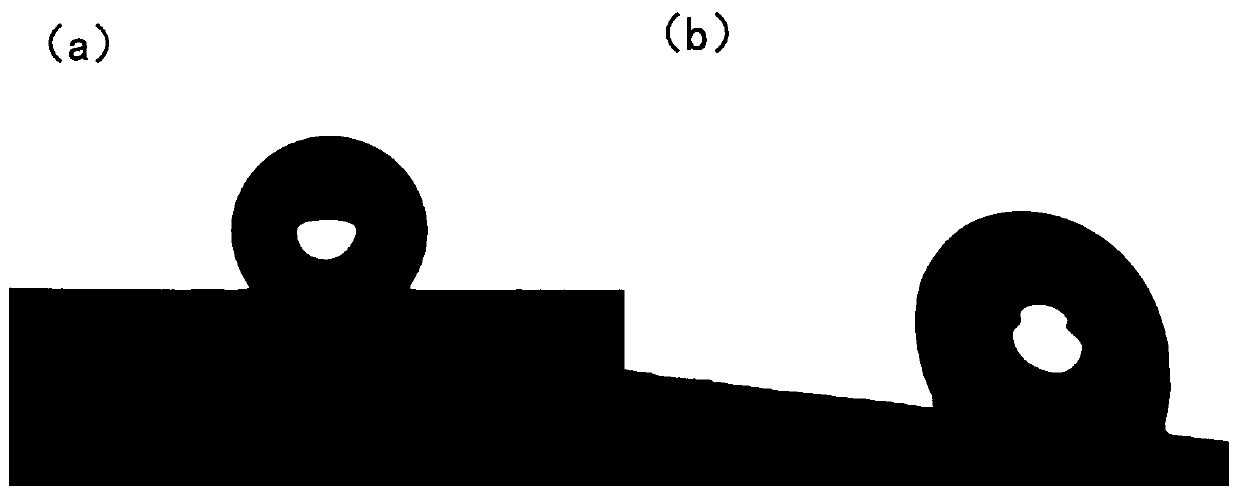

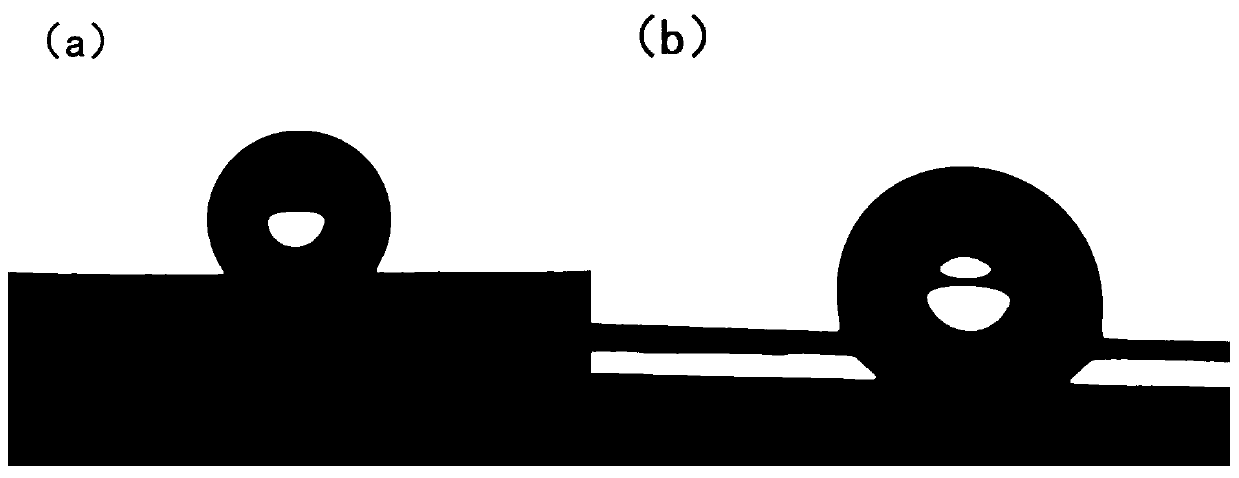

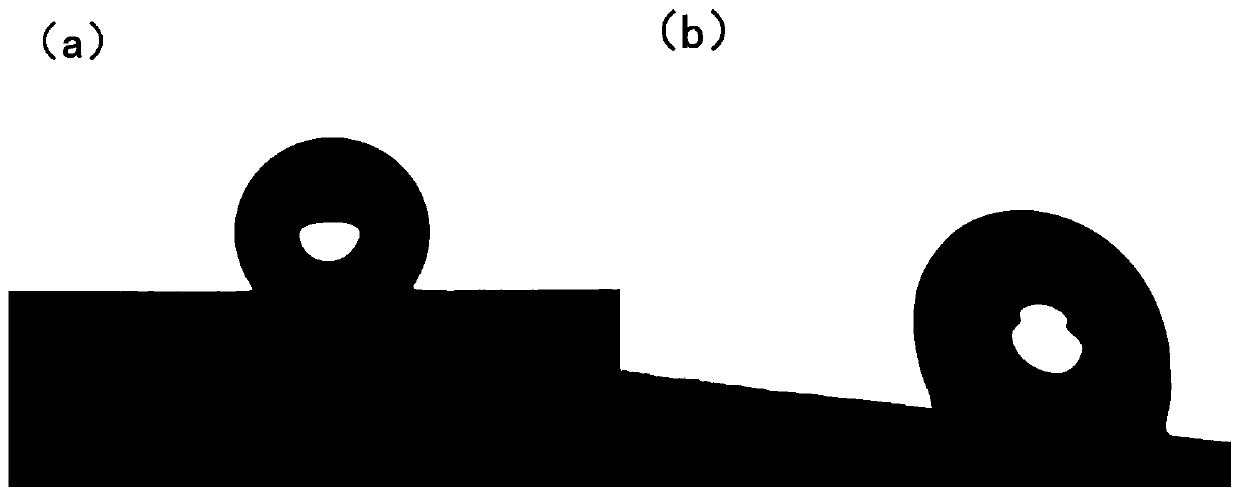

[0029] (1) Using pulsed laser scanning to process the pretreated stainless steel surface into a super-hydrophilic surface;

[0030] (2) baking the super-hydrophilic surface treated in step (1) to obtain a super-hydrophobic surface;

[0031] (3) Use pulsed laser to scan the superhydrophobic surface in step (2) to process multiple superhydrophobic regions and multiple superhydrophilic regions alternately arranged in wedge-shaped or triangular sub-arrays, and each sub-array is distributed with superhydrophobic Hydrophilic pooling area, that is, a super-hydrophobic-super-hydrophilic surface.

[0032] In the present invention, the required structural pattern can be compiled on the surface of the superhydrophobic region in step (2), and then the structural pattern can be processed by pulsed laser scanning, so ...

Embodiment 1

[0054] This embodiment provides a method for preparing a stainless steel super-hydrophobic-super-hydrophilic surface, comprising the steps of:

[0055] (1) Use a metallographic sample pre-grinder with a power of 370W, a grinding disc speed of 450 rpm, and a grinding disc diameter of 230 mm to polish the surface of the 304 stainless steel to be treated. During the polishing process, the auxiliary diameter is 200 mm, 1000 Purpose SiC water sandpaper is used to polish the surface of stainless steel, and the polishing range is 100cm 2 , the polishing time was 10 minutes, and the stainless steel after surface polishing was obtained; then, the stainless steel after surface polishing was cleaned with an ultrasonic cleaner, and the ultrasonic frequency of the ultrasonic cleaner was 40kHz, and the surface of the stainless steel was flooded with deionized water with a resistivity of 18.25 megohms , wash continuously at room temperature for 30 minutes, and dry naturally or with cold air ...

Embodiment 2

[0061] This embodiment provides a method for preparing a stainless steel super-hydrophobic-super-hydrophilic surface, comprising the steps of:

[0062] (1) adopt the method identical with embodiment 1 to carry out pretreatment to 304 stainless steel surface, obtain clean stainless steel sample;

[0063] (2) Use a short-pulse laser to perform laser scanning processing on the clean stainless steel sample in step (1), and process a super-hydrophilic surface with numerous microstructures on the surface of the stainless steel sample. The laser wavelength is 1064nm, and the laser pulse width is 220ns. Single pulse The energy is 0.60mJ, and the repetition frequency is 150kHz; the moving platform device is used for laser scanning, the clean stainless steel sample obtained in step (1) is fixed on the moving working platform, and the laser beam is focused on the sample by using a lens to make the stainless steel sample Relative to the focused etching spot of the ultrafast laser beam, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com