Reflecting-type blue laser lighting assembly

A laser lighting and reflective technology, applied in the field of lighting, can solve problems such as inability to balance heat dissipation at the same time, thermal quenching of fluorescent substances, immature visual effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

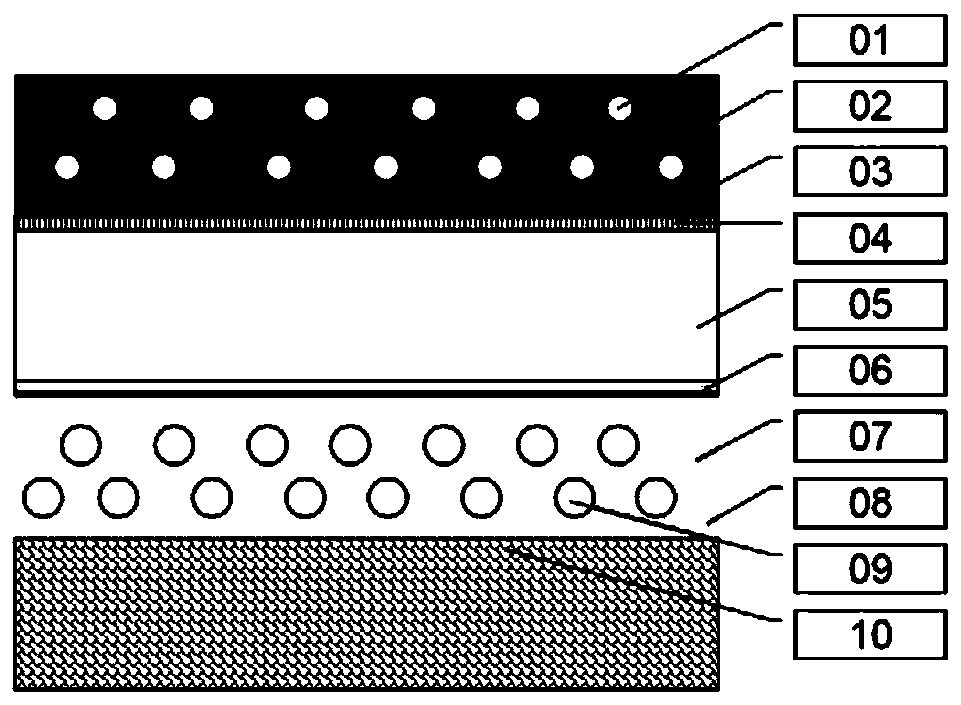

[0059] Will Y 3 Al 5 O 12 : Ce phosphor powder and low melting point glass powder are mixed uniformly according to the mass ratio of 1:1, and appropriate amount of terpineol is added during mixing to adjust the viscosity of the slurry. Then, the above-mentioned slurry was applied to a sapphire substrate plated with a reflective film that enhances yellow light reflection on one side, and the thickness of the paint was 100 μm and the thickness of the substrate was 1 mm. Hollow alumina (outer diameter is 2μm, hollow diameter is 0.4μm) and low melting point glass powder are mixed uniformly according to the mass ratio of 1:99, and appropriate amount of terpineol is added during mixing to adjust the viscosity of the slurry. Then, the above-mentioned slurry was applied to a sapphire substrate plated with an antireflection coating for enhancing blue light transmission, and the thickness of the application was 100 μm. Then put the slurry-bearing substrate (the surface coated with the an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com