A kind of cdse/cds nanorod, polarizing film and preparation method thereof

A polarizing film and nanorod technology, applied in the field of quantum dots, can solve problems such as energy loss and complex stacking structure, achieve high quantum yield, high luminous efficiency, and realize the effect of light output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

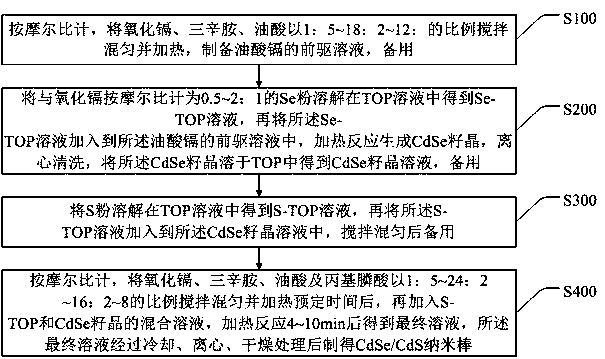

[0072] 1. Preparation of CdSe / CdS core-shell nanorods:

[0073] (1) Preparation of CdSe seed crystal: 60 mg of cadmium oxide (CdO), 2.8 g of trioctylamine (Trioctylamine, TOA), 1.2 g of oleic acid (Oleic acid, OA) were mixed and stirred evenly in a 50 mL three-necked flask , heated to 170 °C under vacuum and degassed for 1 h. Under Ar atmosphere, the solution was heated to 300°C to fully dissolve cadmium oxide to form a colorless and transparent solution. Subsequently, 1.5 g of trioctylphosphine (Trioctylphosphine, TOP) was quickly injected into the flask, and the temperature of the solution decreased slightly. When the temperature of the solution rose to 300 °C, a mixed solution of 40 mg Se and 2 mL TOP was injected into the flask, and the reaction was maintained at 300 °C for 5 min. After the reaction was completed, the solution was cooled to 100 °C and poured into a centrifuge tube, ethyl acetate and methanol were added to precipitate it, and the precipitate was taken out...

Embodiment 2

[0078] 1. Preparation of CdSe / CdS core-shell nanorods:

[0079] (1) Preparation of CdSe seed crystal: 128.4 mg of cadmium oxide (Cadmium oxide, CdO), 3.53 g of trioctylamine (Trioctylamine, TOA), 2.06 g of oleic acid (Oleic acid, OA) were mixed and stirred evenly in a 50 mL three-necked flask , heated to 170 °C under vacuum and degassed for 1 h. Under Ar atmosphere, the solution was heated to 300°C to fully dissolve cadmium oxide to form a colorless and transparent solution. Subsequently, 1.5 g of trioctylphosphine (Trioctylphosphine, TOP) was quickly injected into the flask, and the temperature of the solution decreased slightly. When the temperature of the solution rose to 320 °C, a mixed solution of 79 mg Se and 2 mL TOP was injected into the flask, and the reaction was maintained at 320 °C for 5 min. After the reaction was completed, the solution was cooled to 100 °C and poured into a centrifuge tube, ethyl acetate and methanol were added to precipitate it, and the preci...

Embodiment 3

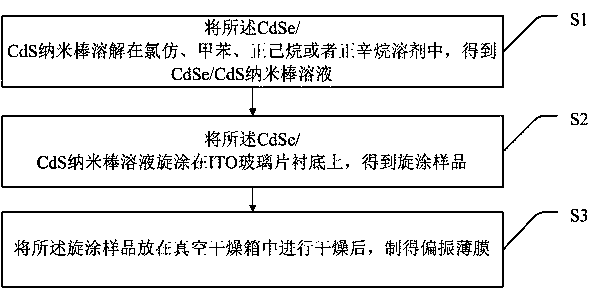

[0084] 1. A preparation method of CdSe / CdS nanorods:

[0085] Add cadmium oxide, trioctylamine and oleic acid into the flask at a ratio of 1:5:2 by molar ratio, stir evenly, vacuumize at 160°C for 50 minutes, and then heat to 300°C in an Ar gas environment to oxidize The cadmium is fully dissolved to obtain a colorless transparent solution; the mixed solution of selenium powder and TOP is added to the colorless transparent solution, and the reaction is carried out at 280° C. for 4 minutes to obtain an intermediate mixed solution; the intermediate mixed solution is cooled to Pour it into a centrifuge tube after 80°C, add ethyl acetate and methanol to precipitate it, take out the precipitate, add toluene and methanol and centrifuge once to obtain CdSe seed crystals, and dissolve the CdSe seed crystals in TOP solution to obtain CdSe seed crystal solution, set aside; dissolving S powder in TOP solution to obtain S-TOP solution, then adding the S-TOP solution into the CdSe seed sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com