Method of one-pot preparation of UIO-66-NH2/functional monomer composite material, and application of the composite material for adsorption of antibiotics

A technology of UIO-66-NH2 and functional monomers, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as poor treatment effect of macrolide antibiotics, and achieve The effect of environmental friendliness and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

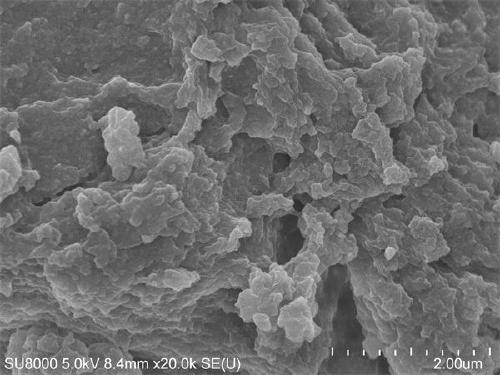

[0014] Accurately weigh 0.2332g of zirconium tetrachloride and 0.1661g of 2-aminoterephthalic acid in 50mL of N,N-dimethylformamide, then add 0.2073g of 2-acrylamide-2-methylpropanesulfonic acid, 0.88mL of cross-linking agent ethylene glycol dimethacrylate and 10mg of initiator azobisisobutyronitrile were transferred to a stainless steel hydrothermal reactor with a tetrafluoroethylene liner, and reacted at 120°C for 24h. After cooling to room temperature, centrifuge and wash three times with methanol at 6000 rpm, and dry to obtain UIO-66-NH 2 / Functional monomer composites.

Embodiment 2

[0016] Accurately weigh 0.4664g of zirconium tetrachloride and 0.1661g of 2-aminoterephthalic acid in 50mL of N,N-dimethylformamide, then add 0.2073g of 2-acrylamide-2-methylpropanesulfonic acid, 0.88mL of cross-linking agent ethylene glycol dimethacrylate and 10mg of initiator azobisisobutyronitrile were transferred to a stainless steel hydrothermal reactor with a tetrafluoroethylene liner, and reacted at 120°C for 24h. After cooling to room temperature, centrifuge and wash three times with methanol at 6000 rpm, and dry to obtain UIO-66-NH 2 / Functional monomer composites.

Embodiment 3

[0018] Accurately weigh 0.1166g of zirconium tetrachloride and 0.042g of 2-aminoterephthalic acid in 50mL of N,N-dimethylformamide, then add 0.2073g of 2-acrylamide-2-methylpropanesulfonic acid, 0.88mL of cross-linking agent ethylene glycol dimethacrylate and 10mg of initiator azobisisobutyronitrile were transferred to a stainless steel hydrothermal reactor with a tetrafluoroethylene liner, and reacted at 120°C for 24h. After cooling to room temperature, centrifuge and wash three times with methanol at 6000 rpm, and dry to obtain UIO-66-NH 2 / Functional monomer composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com