Green environmental-friendly building panel, and preparation method thereof

A green environmental protection, building board technology, applied in the field of building materials, can solve problems such as pollution, consumption of large resources, environmental pollution, etc., and achieve the effect of reducing costs, being beneficial to environmental protection, and having good environmental performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

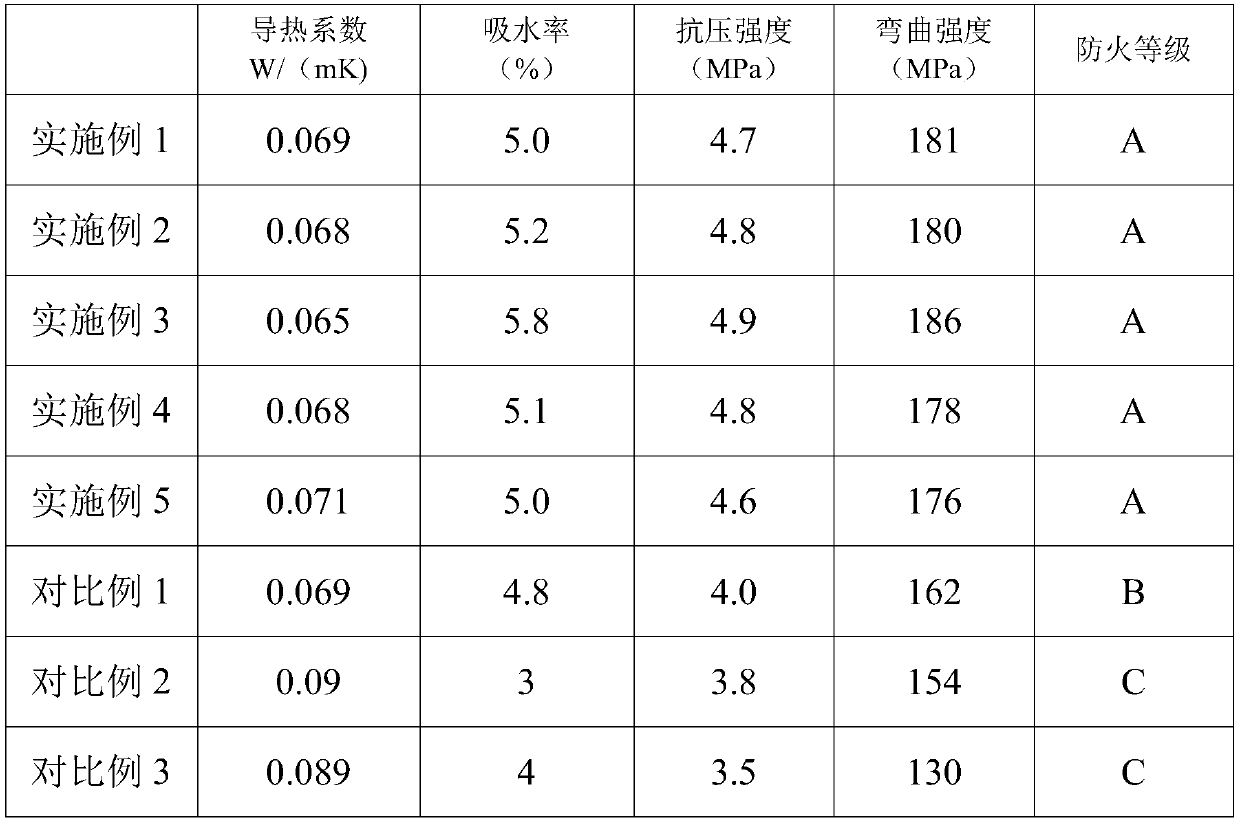

Examples

Embodiment 1

[0021] A green environmental protection building board, comprising the following raw materials in parts by weight: 30 parts of waste glass, 28 parts of waste rubber particles, 81 parts of fly ash, 50 parts of diatomaceous earth, 28 parts of quartz sand, 27 parts of foaming agent, foam stabilizer 10 parts, polypropylene fiber 17 parts, straw fiber 11 parts, wetting agent 12 parts.

Embodiment 2

[0023] A green environmental protection building board, comprising the following raw materials in parts by weight: 48 parts of waste glass, 42 parts of waste rubber particles, 98 parts of fly ash, 64 parts of diatomite, 38 parts of quartz sand, 43 parts of foaming agent, foam stabilizer 20 parts, polypropylene fiber 25 parts, straw fiber 23 parts, wetting agent 22 parts.

Embodiment 3

[0025] A green environmental protection building board, comprising the following raw materials in parts by weight: 41 parts of waste glass, 37 parts of waste rubber particles, 92 parts of fly ash, 58 parts of diatomite, 32 parts of quartz sand, 32 parts of foaming agent, foam stabilizer 15 parts, polypropylene fiber 21 parts, straw fiber 18 parts, wetting agent 17 parts.

[0026] The preparation process of the green environmental protection building board of the above-mentioned embodiments 1-3 comprises the following steps:

[0027] S1. Foam concrete: Take raw materials according to the above weight ratio, mix the pulverized fly ash, diatomaceous earth, foaming agent, and foam stabilizer, add water 3 times the weight of the mixture, import it into the foaming cylinder, and foam for 2.3 h, the speed of the foam cylinder is 0.2m / s, and then the foaming liquid, polypropylene fiber, and straw fiber are introduced into an air compressor with a pressure of 0.5MPa to obtain foam conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com