Method for preparing olefins from synthesis gas

A synthesis gas and olefin technology, applied in the direction of hydrocarbon production from carbon oxides, purification/separation of hydrocarbons, chemical instruments and methods, etc., can solve the problems of short regeneration period, fast coking of catalysts, low yield of olefins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

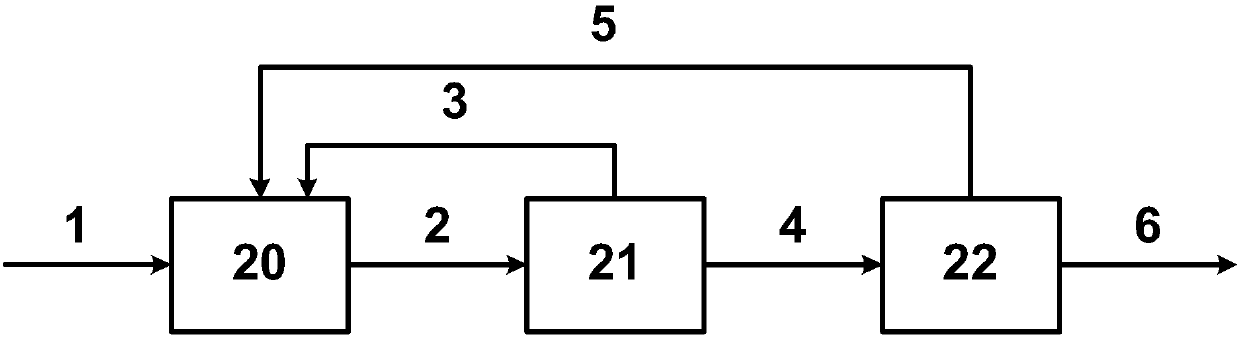

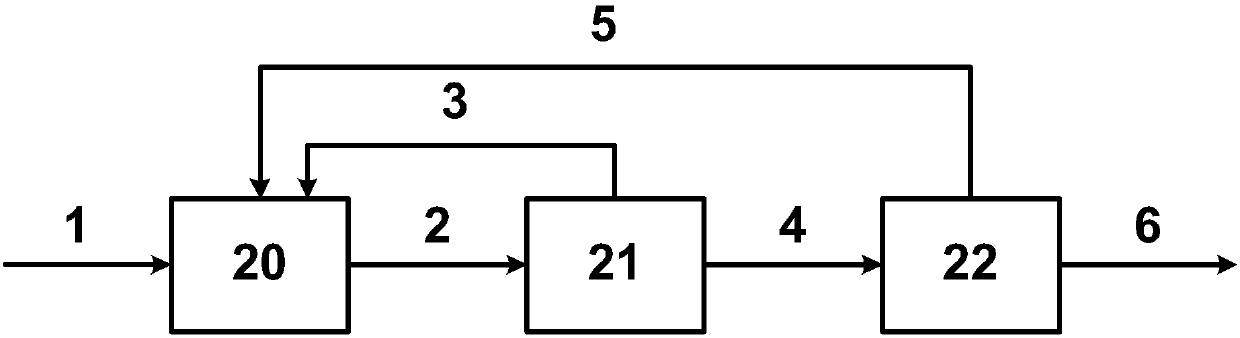

[0037] The synthesis gas stream is calculated in moles, the ratio of hydrogen to carbon monoxide is 5, 10% of the stream I is recycled to the reaction zone, and 60% of the stream II is recycled back to the reaction zone. The decarburization zone uses methyldiethanolamine as the absorbent, and the dehydrogenation zone adopts the PSA separation method , catalyst life increased by 5.6%, and olefin yield increased by 1.20%.

Embodiment 2

[0039]The synthesis gas stream is calculated in moles, the ratio of hydrogen to carbon monoxide is 4, 10% of stream I is recycled back to the reaction zone, and 60% of stream II is recycled back to the reaction zone, the decarburization zone uses methyldiethanolamine as the absorbent, and the dehydrogenation zone adopts the PSA separation method , catalyst life increased by 5.4%, and olefin yield increased by 1.21%.

Embodiment 3

[0041] The synthesis gas stream is calculated in moles, the ratio of hydrogen to carbon monoxide is 3, 10% of stream I is recycled to the reaction zone, and 60% of stream II is recycled back to the reaction zone, the decarburization zone uses methyldiethanolamine as the absorbent, and the dehydrogenation zone adopts the PSA separation method , catalyst life increased by 5.2%, and olefin yield increased by 1.23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com