Method for preparing carboxylated nanocellulose by utilizing citric acid hydrolysis in combination with ultrasonic assistance

A nanocellulose, ultrasonic-assisted technology is applied in the field of green preparation of nanocellulose to achieve the effects of reducing process and drug consumption, stable dispersion and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

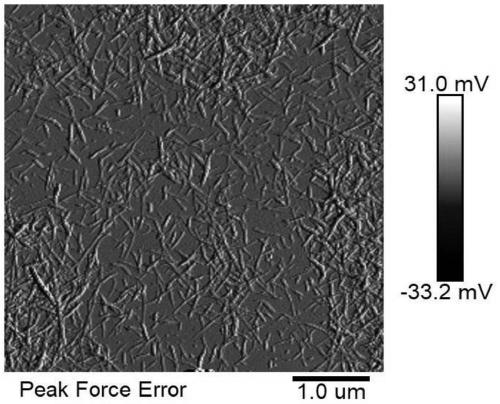

Image

Examples

Embodiment 1

[0039] Example 1: Preparation of carboxylated nanocellulose by citric acid hydrolysis combined with ultrasound-assisted one-step method

[0040] (1) At a temperature of 100°C, 5g of dry bleached bagasse pulp board was pulverized and added to an aqueous citric acid solution (80g citric acid, 20ml deionized water) with a concentration of 80wt% for 4 hours to obtain a hydrolysis suspension.

[0041] (2) Vacuum filtration of the hydrolyzed suspension through a G4 sand core funnel to obtain solid fibers and filtrate. The fibers were repeatedly added with deionized water and centrifuged at 4000 r / min to wash until neutral, and the filtrate was subjected to rotary evaporation at 70 °C and 60 r / min to obtain a white citric acid crystalline solid.

[0042] (3) The washed fibers were sonicated at 900W for 20min by an ultrasonic cell crusher (there was a 5s interval after each 5s of sonication). After the sonication, 200ml of deionized water was added and sonicated for 20min.

[0043](4...

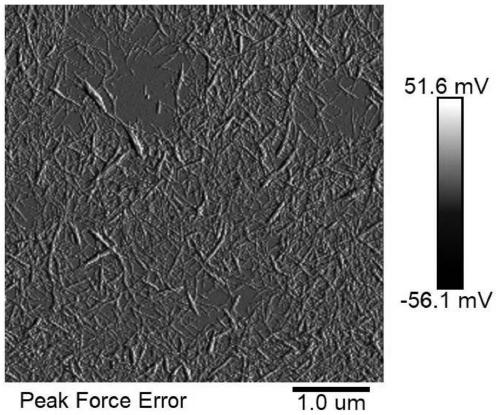

Embodiment 2

[0045] Example 2: Preparation of carboxylated nanocellulose by citric acid hydrolysis combined with ultrasound-assisted one-step method

[0046] (1) At a temperature of 100°C, add 5g of dry bleached bagasse pulp board to a citric acid aqueous solution (70g citric acid, 30ml water) with a concentration of 70wt% for 4h to obtain a hydrolysis suspension.

[0047] (2) Vacuum filtration of the hydrolyzed suspension through a G4 sand core funnel to obtain solid fibers and filtrate. The fibers were repeatedly added with deionized water and centrifuged at 4000 r / min to wash until neutral, and the filtrate was subjected to rotary evaporation at 70 °C and 60 r / min to obtain a white citric acid crystalline solid.

[0048] (3) The washed fibers were sonicated at 900W for 20min by an ultrasonic cell crusher (there was a 5s interval after each 5s of sonication). After the sonication, 200ml of deionized water was added and sonicated for 20min.

[0049] (4) After centrifuging the cellulose s...

Embodiment 3

[0051] Example 3: Hydrolysis of citric acid combined with ultrasonic-assisted one-step preparation of carboxylated nanocellulose

[0052] (1) At a temperature of 100°C, 5g of dry bleached wood pulp board was pulverized and added to an aqueous solution of citric acid (80g citric acid, 20ml water) with a concentration of 80wt% for 4h to obtain a hydrolysis suspension.

[0053] (2) Vacuum filtration of the hydrolyzed suspension through a G4 sand core funnel to obtain solid fibers and filtrate. The fibers were repeatedly added with deionized water and centrifuged at 4000 r / min to wash until neutral, and the filtrate was subjected to rotary evaporation at 70 °C and 60 r / min to obtain a white citric acid crystalline solid.

[0054] (3) The washed fibers were sonicated at 900W for 20min by an ultrasonic cell crusher (there was a 5s interval after each 5s of sonication). After the sonication, 200ml of deionized water was added and sonicated for 20min.

[0055] (4) After centrifuging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com