Preparation method for aramid fiber 1414 based composite material

A fiber composite material, aramid fiber technology, applied in fiber processing, spinning solution preparation, wet spinning, etc., can solve the problems of restricting market development, high performance and stability requirements, and achieve sufficient solubility, guaranteed strength, The effect of increasing fiber modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

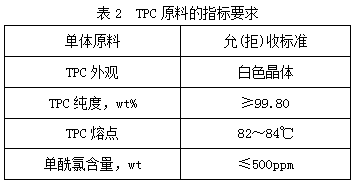

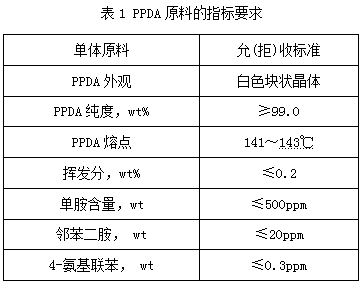

[0037] A preparation method based on aramid fiber 1414 fiber composite material, comprising the steps of:

[0038] A. polymerization

[0039] First, weigh the raw material poly-p-phenylene terephthalamide (PPDA) and raw material terephthaloyl chloride (TPC); dissolve poly-p-phenylene terephthalamide in NMP / CaCl 2 In the process, the premix is obtained, and then placed in the prepolymer mixer; secondly, 50% terephthaloyl chloride is also placed in the prepolymer mixer, and the two are reacted to obtain the prepolymer, and then the The prepolymer and the remaining 50% of terephthaloyl chloride were mixed in a polymerization mixer to obtain a mixture; finally, the mixture was placed in a polymerization reactor for 6 minutes to obtain a polymer;

[0040] Grinding, beating, washing, purifying and drying the polymer, storing it for later use;

[0041] B. spinning

[0042] Put the polymer obtained in step A in a dissolving mixer, and at the same time, pass sulfuric acid into t...

Embodiment 2

[0046] On the basis of Embodiment 1, the difference of this embodiment is:

[0047] In step A, the reaction 7min of the mixture in the polymerization reactor;

[0048] In step B, after passing sulfuric acid into the dissolution mixer, it was mixed and dissolved at 85°C for 60 minutes;

[0049] In step B, heat treatment at 170°C for 0.8s;

[0050] In step C, in the oiling treatment, the oil content is controlled to 0.75%.

Embodiment 3

[0052] On the basis of embodiment 1-2, the difference of this embodiment is:

[0053] In step A, the reaction 7min of the mixture in the polymerization reactor;

[0054] In step B, after passing sulfuric acid into the dissolution mixer, it was mixed and dissolved at 80°C for 40 minutes;

[0055] In step B, heat treatment at 150°C for 0.5s;

[0056] In step C, in the oiling treatment, the oil content is controlled to 0.68%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com