High-thermal conductivity fast-response phase change energy-storage composite material and preparation method thereof

A composite material and phase change energy storage technology, applied in the field of high thermal conductivity and fast response phase change energy storage composite materials and their preparation, can solve the problems of low thermal conductivity and slow response speed, and achieve high thermal conductivity and improved response speed. , the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

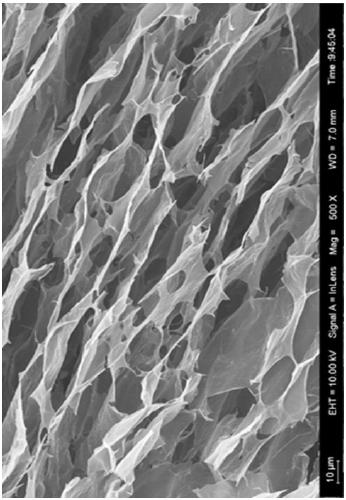

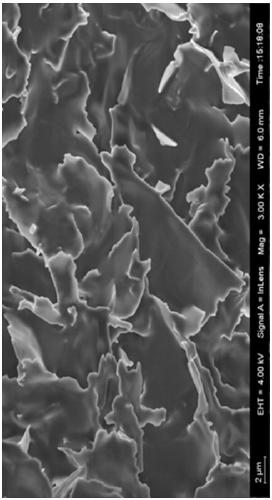

[0039] Specific Embodiment 1: This embodiment describes a high thermal conductivity and fast response phase change energy storage composite material. The composite material is composed of a high thermal conductivity and highly oriented graphene network structure as a skeleton, impregnated with an organic phase change material. Compared with traditional phase change materials, the phase change energy storage composite material of the present invention has an order of magnitude higher thermal conductivity, which can reach 180W / m·K. The thermal conductivity is high, and heat can be quickly transferred to phase change materials (paraffin wax etc.), so the phase change response speed is fast; the high orientation is aimed at the graphene network structure. Graphene itself is a two-dimensional material, sheet-like, with good heat conduction along the in-plane direction of the sheet, and poor heat conduction in the direction perpendicular to the sheet, so only using Only when they are...

specific Embodiment approach 2

[0040] Embodiment 2: A method for preparing the high thermal conductivity and fast response phase change energy storage composite material described in Embodiment 1, the method includes the following preparation steps:

[0041] Step 1: Preparation of high thermal conductivity and high orientation graphene network structure and density or porosity control;

[0042] Step 2: impregnating the organic phase change material.

[0043] Specific embodiment three: the preparation method of a high thermal conductivity and fast response phase change energy storage composite material described in specific embodiment two, the step one described is one of the following two methods:

[0044] Method 1: Directional freeze-drying method

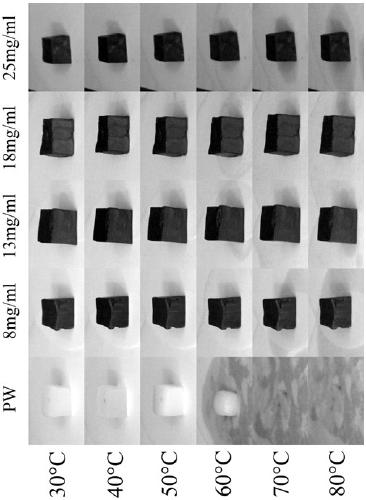

[0045](1) Preparation of graphene oxide solutions with different concentrations: Take 5 mg / mL graphene oxide aqueous solution in a centrifuge tube, centrifuge through a centrifuge, take away the supernatant, and obtain 8 ~25mg / mL graphene oxide aqueous soluti...

Embodiment 1

[0060] (1) Preparation of highly oriented graphene network structure by directional freeze-drying method.

[0061] (a) Preparation of graphene oxide solutions with different concentrations: Take 5 mg / mL graphene oxide solution in a centrifuge tube, centrifuge through a centrifuge for 4 times, remove 2 / 3 volume of the supernatant, and obtain 15 mg / mL mL concentration of graphene oxide solution, followed by stirring for 2 hours and ultrasonic vibration for 1 hour to prevent graphene oxide sheets from agglomerating. (b) Freeze-drying: Pour the graphene oxide solution into the mold (the bottom of the mold is made of copper and the surrounding is made of polytetrafluoroethylene), cool down with liquid nitrogen, freeze into a block from bottom to top, and put it into In the freeze dryer, take it out after 7 days to obtain a graphene oxide network structure with graphene oxide oriented along the Z axis, and the density of this structure is 15 mg / cm 3 . (c) Reduction of highly orien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com