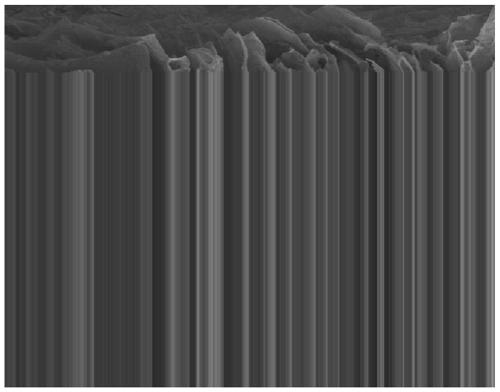

Two-dimensional MXene membrane with vertical channel structure and preparation method thereof

A vertical channel, drying technology, applied in the field of MXene membrane, can solve the problems of reduced transmission rate, easy re-stacking and agglomeration, etc., to achieve the effect of excellent specific surface area, simple method, and green process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of a two-dimensional MXene film with a vertical pore structure, comprising the following steps:

[0040] (1) Add 7g of lithium fluoride to 200mL of 6mol / L hydrochloric acid solution, stir well, then add 4g of Ti 3 AlC 2 powder, stirred and reacted for 36 hours, centrifuged and washed at 2500rpm until the pH of the upper solution was neutral, and then dried at 50°C for 48 hours to obtain Ti 3 C 2 powder;

[0041] (2) 1g Ti 3 C 2 The powder was added to 500mL deionized water, ultrasonicated for 1 hour, centrifuged at 2500rpm for 1h, and the upper liquid was absorbed to obtain a solution of two-dimensional MXene nanosheets with a concentration of 2mg / mL;

[0042] (3) Take 40mL of the MXene nanosheet solution obtained in step (2), add 10mL of water, insert the working electrode conductive glass FTO and the counter electrode into the solution, apply a DC voltage of 15V, and take it out after 4min;

[0043] (4) The substrate deposited with MXene nan...

Embodiment 2

[0047] A preparation method of a two-dimensional MXene film with a vertical pore structure, comprising the following steps:

[0048] (1) Add lithium fluoride (10g) into hydrochloric acid solution (12mol / L, 150mL), stir evenly, add 8g of MAX powder (V 2 AlC), stirred at 500rpm for 24h, centrifuged at 2500rpm for 10min, washed with deionized water until the pH was 7, and dried at 80°C for 16h to obtain MXene powder;

[0049] (2) Disperse the MXene powder into water, sonicate for 2 hours, centrifuge, and take the upper layer solution, which is the MXene nanosheet solution with a concentration of 1 mg / mL;

[0050] (3) Take 25mL of the MXene nanosheet solution obtained in step (2), add 10mL of water, insert the working electrode base porous stainless steel mesh and the counter electrode into the solution, apply a 20V DC voltage, and take it out after 3min;

[0051] (4) Put the substrate deposited with MXene nanosheets into a liquid nitrogen environment to cool for 8 minutes (-196°...

Embodiment 3

[0053] A preparation method for a two-dimensional MXene film, comprising the following steps:

[0054] (1) Add lithium fluoride (8g) into hydrochloric acid solution (12mol / L, 100mL), stir well, add 10g of MAX powder (Ti 2 AlC), stirred at 350rpm for 24h, centrifuged at 2500rpm for 10min, washed with deionized water until the pH was 6, and dried at 80°C for 16h to obtain MXene powder;

[0055] (2) Disperse the MXene powder into water, sonicate for 1.5h, centrifuge, and take the upper layer solution, which is the MXene nanosheet solution with a concentration of 2mg / mL;

[0056] (3) Take 30mL of the MXene nanosheet solution obtained in step (2), add 10mL of water, insert the working electrode substrate titanium sheet and the counter electrode into the solution, apply a 5V DC voltage, and take it out after 10min;

[0057] (4) Put the substrate containing a large number of MXene nanosheets into a liquid nitrogen environment to cool for 4 minutes (-196°C), take it out and transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com