A kind of film and preparation method thereof and qled device

A device and thin film technology, which is applied in the field of thin film and its preparation, can solve the problems that the luminous efficiency of QLED devices needs to be improved, and achieve the effects of avoiding structural damage, meeting comprehensive performance requirements, and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

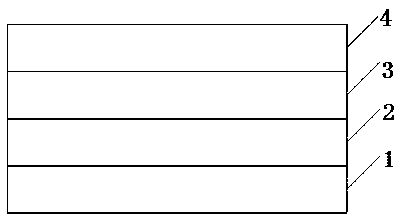

[0077] The preparation steps of the QLED device are as follows:

[0078] A first Cu layer of 10nm is vapor-deposited on the glass ITO substrate;

[0079] Mix 8 mg of NiO nanoparticles and 8 mg of Cu into the ethanol solution to obtain a blend solution with a concentration of 4 mg / ml, then spin-coat the blend solution on the first Cu layer, and heat it at 120 ° C for 15 min to obtain the NiO layer and the second Cu layer. A graded film with a thickness of 40nm formed by two Cu layers, in which the NiO layer is located under the second Cu layer.

[0080] Spin-coat TFB on the second Cu layer with a thickness of 10 nm;

[0081] Spin-coat QDs on the TFB layer with a thickness of 30nm;

[0082] Evaporate BCP on the QD with a thickness of 50nm,

[0083]Evaporate Al on the BCP to obtain a QLED device, the intensity of the QLED device is shown in Figure 4 .

Embodiment 2

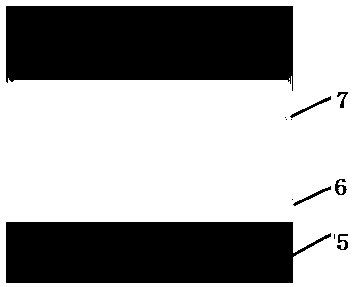

[0085] The preparation steps of the QLED device are as follows:

[0086] Preparation of a blend solution: 4 mg of NiO nanoparticles and 6 mg of Cu were mixed into a dipropylene glycol solution with a concentration of 4 mg / ml.

[0087] After spin-coating the above blend on a glass ITO substrate, vacuum 5×10 at 70°C 2 Pa is maintained for 15min to obtain a 40nm thick gradient film formed by the NiO layer and the second Cu layer, in which the second Cu layer is located under the NiO layer; then the first Cu layer of 10nm is evaporated;

[0088] Spin-coat TFB on the first Cu layer with a thickness of 10 nm;

[0089] Spin-coat QDs on TFB with a thickness of 30nm;

[0090] Evaporate BCP on the QD with a thickness of 50nm;

[0091] Evaporate Al on the BCP to obtain a QLED device, the intensity of the QLED device is shown in Figure 4 .

Embodiment 3

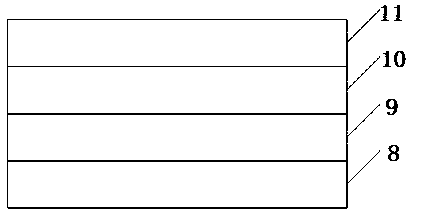

[0100] The preparation steps of the QLED device are as follows:

[0101] A first Cu layer of 10nm is vapor-deposited on the glass ITO substrate;

[0102] Mix 8 mg of NiO nanoparticles and 8 mg of Cu into the ethanol solution to obtain a blend solution with a concentration of 4 mg / ml, then spin-coat the blend solution on the first Cu layer, and heat it at 120 ° C for 15 min to obtain the NiO layer and the second Cu layer. A graded film with a thickness of 40nm formed by two Cu layers, in which the NiO layer is located under the second Cu layer.

[0103] Spin-coat QDs on the second Cu layer with a thickness of 30 nm;

[0104] Al is evaporated on the QDs to obtain QLED devices.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com