Supported catalyst, preparation method and applications thereof, and Fischer-Tropsch synthesis method

A supported catalyst, Fischer-Tropsch synthesis technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to achieve improved stability, improved utilization, high catalysis active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] According to a preferred embodiment of the present invention, the method further includes washing the core-shell structure product obtained in step (2), so that the impurity content of metal elements other than cobalt and group IVB metal elements is not greater than 100 ppm. It can be rinsed or rinsed directly with water or organic solvents. The organic solvent may be, for example, one or more of ethanol, propanol, ethylene glycol, and glycerol.

[0046] The loading of step (3) can adopt various existing methods, for example, can refer to the existing impregnation method, that is, after the core-shell nanostructure obtained in step (2) is dispersed with a dispersion medium to obtain a dispersion liquid, use this dispersion liquid impregnated carrier. The dispersion medium can be a variety of liquid substances that do not dissolve or cause adverse effects on the core-shell nanostructure and the carrier, and can be water or an organic solvent. The organic solvent can be ...

Embodiment 1

[0058] (1) Preparation of zirconium hydroxide colloid

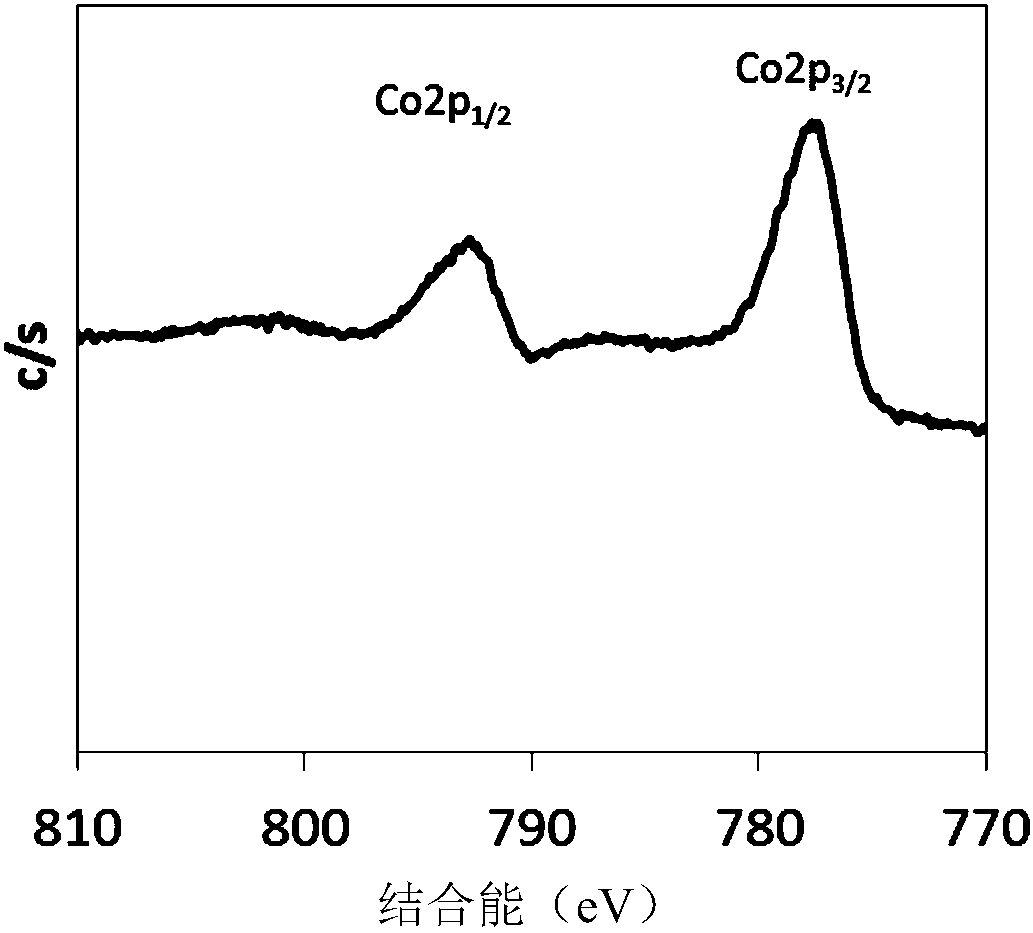

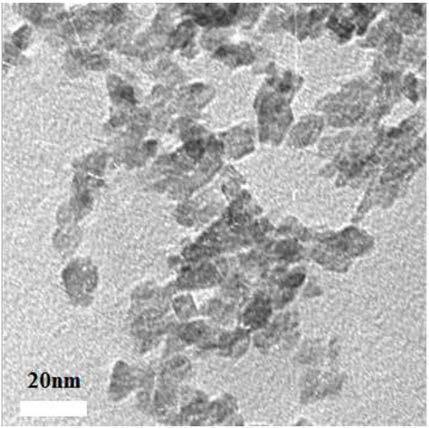

[0059] Mix 268 mL of zirconium oxychloride aqueous solution with a concentration of 0.05 mol / L and 3.84 g of urea, heat up to 85°C for 1 hour, cool to 30°C and age for 8 hours, then centrifugally filter, wash with deionized water three times until the filtrate is washed with silver nitrate The solution was detected without precipitation. TEM of zirconium hydroxide colloid figure 2 shown. figure 1 The TEM shows that the average particle size of zirconium hydroxide colloid is 15nm.

[0060] (2)Co / Zr(OH) 4 Preparation of core-shell structure

[0061] Under the protection of inert gas, in the there-necked flask, the above-mentioned zirconium hydroxide colloid was dispersed in 350ml distilled water, then added 30.8g protective agent PVP-30k (Sinopharm Group, analytically pure) and 6.69g cobalt chloride hexahydrate (Bailingwei, Analytical pure), kept at normal temperature for 15 minutes, after the solid was slowly dissolv...

Embodiment 2

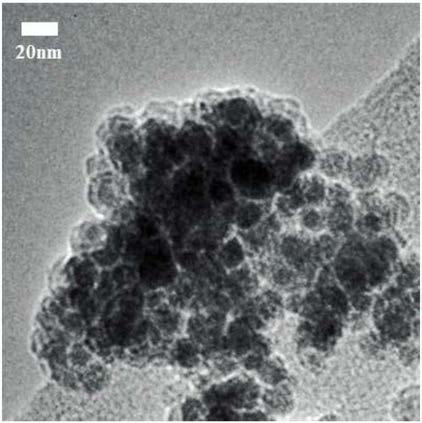

[0069] (1) Titanium hydroxide colloid

[0070] Under the protection of an ice-water bath, 208 mL of TiCl with a concentration of 0.1 mol / L 4 The solution was precipitated with 1.0 wt% ammonia solution to maintain a pH value of 9-11. After aging for 8 hours, it was centrifugally filtered and washed 3 times until the filtrate was detected by silver nitrate solution and no precipitation was formed. TEM shows that the average particle size of titanium hydroxide colloid is 17nm.

[0071] (2)Co / Ti(OH) 4 core-shell structure

[0072] Under the protection of an inert gas, the above-mentioned titanium hydroxide colloid was dispersed in 410ml distilled water, 30.8g protective agent PVP-30k (Sinopharm Group, analytically pure) and 7.0g cobalt acetate tetrahydrate (Bailingwei, analytically pure), and kept for 15 Minutes, after the solid slowly dissolves, use a syringe to quickly inject 80 g of an aqueous solution containing 5.6 g of sodium borohydride (Beijing Reagent, analytically pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com