Microsphere Silicate-1 molecular sieve catalyst and preparation method thereof, and caprolactam preparation method

A technology of molecular sieve and catalyst, applied in the field of preparing caprolactam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

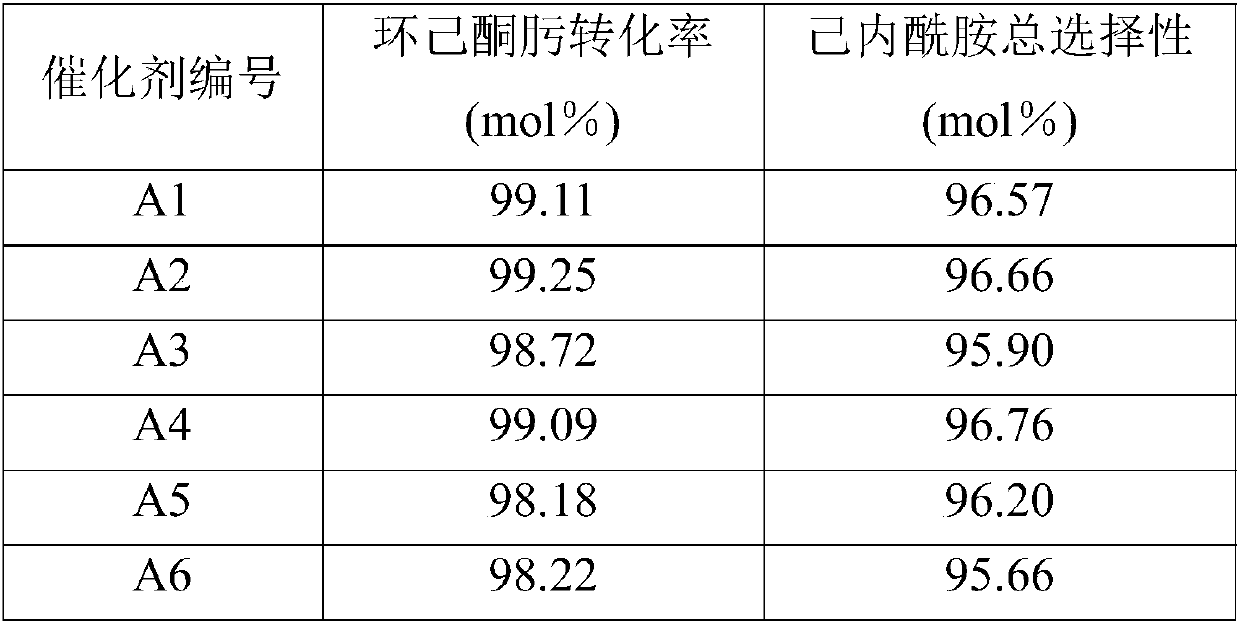

Examples

Embodiment 1

[0082] With 416kg orthosilicate ethyl ester, 360kg 22.5% by weight tetrapropyl ammonium hydroxide (abbreviated as TPAOH), 56.2gFe(NO 3 ) 3 9H 2 O and 415kg water were mixed, stirred at room temperature for 5 hours to form a colloidal mixture with a pH value of 12.8, and SiO in the mixture 2 :TPAOH:H 2 O (molar ratio) = 1:0.2:20, SiO 2 with Fe 3+ The weight ratio is 15347:1, move the above mixture into 2m 3 In a stainless steel reaction kettle, crystallize at 100°C for 3 days, the pH of the crystallized product is 13.57, and then use a 50nm six-tube membrane for membrane filtration and wash with water at 40-60°C. The amount of washing water is 6.8m 3 The pH of the post-crystallization product reached 9.1. Concentrate the slurry obtained after washing to obtain 395kg of molecular sieve slurry with a solid content of 26.8% by weight, send it to microwave drying, and dry it at 100-150°C for 1 hour to obtain about 125kg of Silicate-1 molecular sieve powder.

[0083] The abov...

Embodiment 2

[0090] With 416kg tetraethyl orthosilicate, 360kg 22.5% by weight of tetrapropylammonium hydroxide (abbreviated as TPAOH), 0.236kgAl (NO 3 ) 3 9H 2 O and 410kg of water were mixed, and stirred for 5 hours at room temperature to form a colloidal mixture with a pH value of 12.35, and SiO in the mixture 2 :TPAOH:H 2 O (molar ratio) = 1:0.2:20, SiO 2 with Al 3+ The weight ratio is 7067:1, move the above mixture into 2m 3 In a stainless steel reaction kettle, crystallize at 100°C for 3 days, the pH of the crystallized product is 13.71, then use a 50nm six-tube membrane for membrane filtration and wash with water at 40-60°C, the amount of washing water is 6.6m 3 The pH of the post-crystallization product reached 9.0. Concentrate the slurry obtained after washing to obtain 310kg of molecular sieve slurry with a solid content of 34.5% by weight, send it to microwave drying, and dry it at 100-150°C for 1 hour to obtain about 125kg of Silicate-1 molecular sieve powder.

[0091] T...

Embodiment 3

[0096] With 416kg tetraethyl orthosilicate, 360kg 22.5% by weight of tetrapropylammonium hydroxide (abbreviated as TPAOH), 8.4gZrOCl 2 ·8H 2 O and 420kg of water were mixed and stirred for 5 hours at room temperature to form a colloidal mixture with a pH value of 12.46, and SiO in the mixture 2 :TPAOH:H 2 O (molar ratio) = 1:0.2:20, SiO 2 with Zr 4+ The weight ratio is 50596:1, move the above mixture into 2m 3 In a stainless steel reaction kettle, crystallize at 100°C for 3 days, the pH value of the crystallized product is 13.42, then use a 50nm six-tube membrane for membrane filtration and wash with water at 40-60°C, the amount of washing water is 6.7m 3 The pH of the post-crystallization product reached 9.1. Concentrate the slurry obtained after washing to obtain 310kg of molecular sieve slurry with a solid content of 28.4% by weight, send it to microwave drying, and dry it at 100-150°C for 1 hour to obtain about 127kg of Silicate-1 molecular sieve powder.

[0097] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com