Fluidized bed system and method for hydrogen production by pulse magnetic combined enhanced catalytic reforming of methane

A methane catalysis and reforming technology for hydrogen production, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the catalytic reforming hydrogen production reaction-complicated regeneration device, catalyst particles are easy to form particle agglomerations, and catalyst particles collide Weaken and other problems, achieve the effect of improving sintering phenomenon, reducing adsorption effect, and increasing collision frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

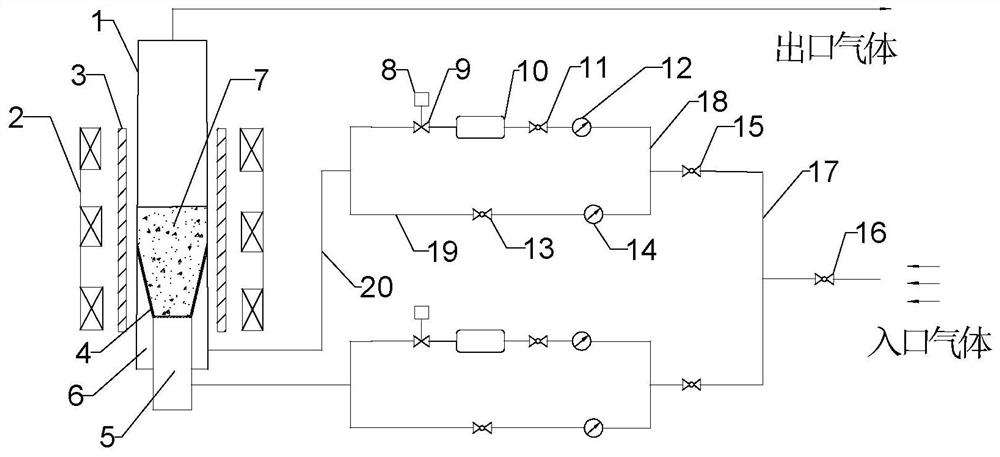

[0033] Specific implementation mode one: combine figure 1To Fig. 2, this embodiment is illustrated, a fluidized bed system of a pulse magnetic combined enhanced methane catalytic reforming hydrogen production in this embodiment, which includes a magnetic fluidized bed reactor and two airflow generating devices, and the magnetic fluidized bed reaction The device includes a fluidized bed reactor 1, a stable magnetic field generator 2, a heater 3, a conical air distribution plate 4, an inner bellows 5, an outer bellows 6 and a bed material layer 7 (referring to the catalyst particle bed material layer), and the fluidized bed The inner side of the lower part of the reactor 1 is provided with a conical air distribution plate 4, the inner bellows 5 is connected to the horizontal section of the conical air distribution plate 4, the lower end of the fluidized bed reactor 1 is provided with an outer bellows 6, and the outer bellows 6 is connected to the conical air distribution plate 4....

specific Embodiment approach 2

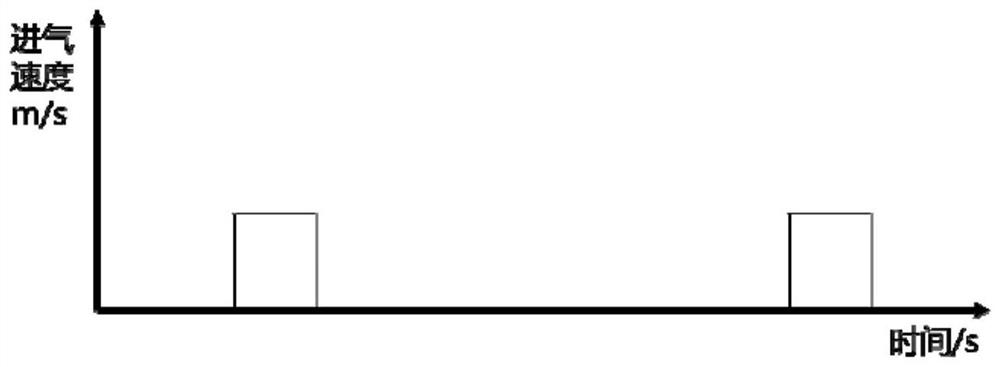

[0036] Specific implementation mode two: combination figure 1 Describe this embodiment, the period of the rectangular wave pulsating air flow of the pulsating air flow generating device of this embodiment is controlled by the solenoid valve 9 and the controller 8, and the controller controls the opening and closing time of the solenoid valve. Such setting makes the frequency of the pulsating airflow more precise and controllable. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Specific implementation mode three: combination figure 1 Describe this embodiment, the two airflow generating devices of this embodiment are connected to the inlet gas through the fourth spherical valve 16, and each airflow generating device includes a continuous airflow generator and a rectangular waveform pulsating airflow generator, and a rectangular waveform pulsating airflow generator Including controller 8, solenoid valve 9, gas buffer tank 10, first ball valve 11 and first rotameter 12; continuous flow generator includes second ball valve 13, second rotameter 14 and third ball valve 15 , the first inlet gas pipeline 17 on the air flow generating device is equipped with a third spherical valve 15, the first inlet gas pipeline 17 is provided with a parallel first branch pipeline 18 and a second branch pipeline 19, the first The branch pipeline 18 and the second branch pipeline 19 are connected in parallel to one end of the output gas pipeline 20, and the other end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com