Graphene strip with neat edges, preparation method and applications thereof

A graphene and edge technology, which is applied in the field of graphene strip preparation, can solve the problems of uneven edges, uncontrollable width, and difficult positioning of strips, and achieves the effect of reducing scattering, maintaining intrinsic properties, and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] As an aspect of the technical solution of the present invention, what it relates to is a kind of preparation method of the graphene strip with neat edges, and it comprises:

[0024] Photolithographic patterning of graphene;

[0025] growing a metal film on the patterned graphene, followed by removing the metal film;

[0026] The patterned graphene is subjected to hydrogen plasma etching treatment to obtain graphene strips with neat edges (also called graphene nano strips).

[0027] In some more specific embodiments, the preparation method further includes: before performing photolithographic patterning, first transferring the graphene onto the substrate.

[0028] Specifically, the preparation method includes: using ordinary photolithography or electron beam lithography to pattern, transfer graphene to the substrate, and then use photolithography or electron beam lithography to expose the required pattern, and the size of the pattern can be in the range of nanometers. ...

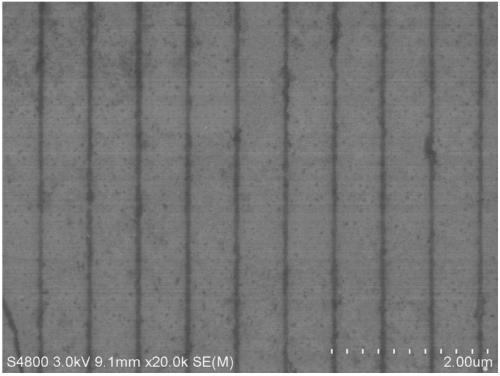

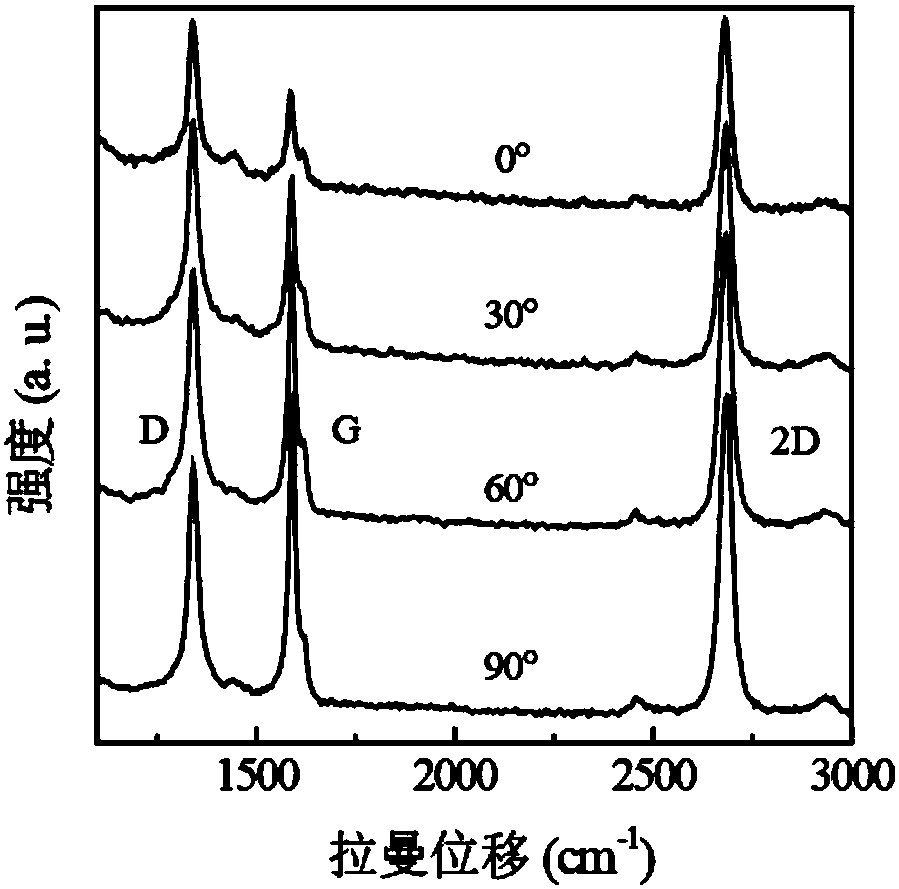

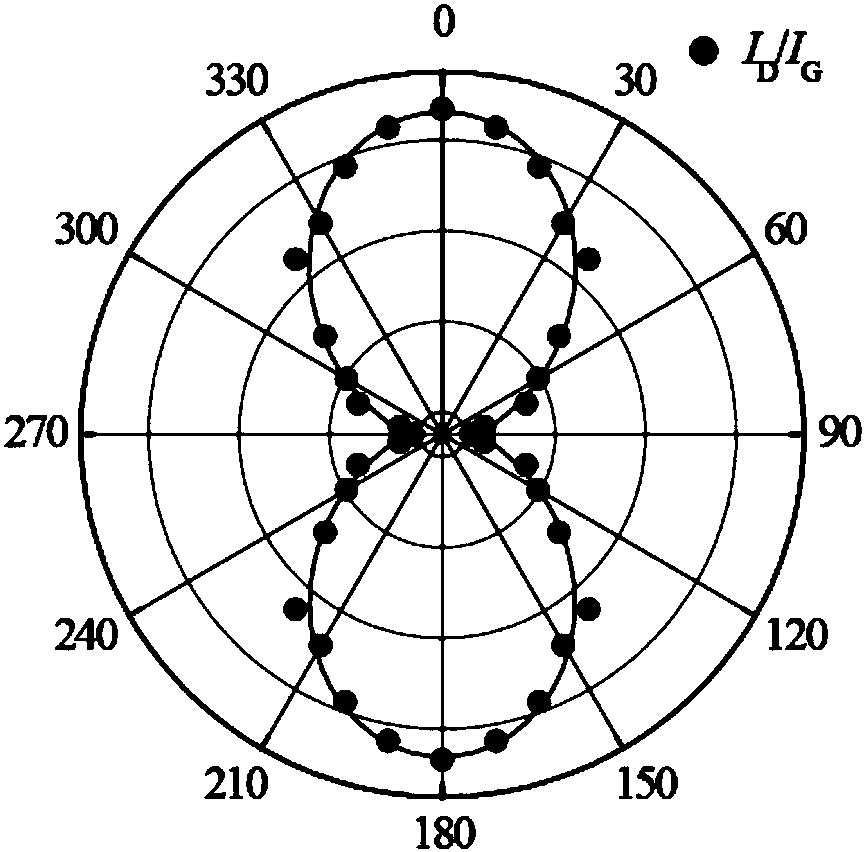

Embodiment 1

[0057] The method for preparing the graphene strips with neat edges in the present embodiment may further comprise the steps:

[0058] (1) The substrate material is a silicon wafer with 300nm silicon dioxide grown by thermal oxidation, and the graphene is migrated after the substrate is cleaned.

[0059] (2) Ordinary lithography or electron beam lithography, glue the sample with graphene migrated on the substrate, and then use photolithography or electron beam lithography to expose the required graphics. The size of the graphics can be in nanoscale or in micron scale.

[0060] (3) Growth of metal film: use magnetron sputtering to grow zinc with a thickness of 20 nm on the sample after photolithography and development.

[0061] (4) Hydrogen plasma etching: at room temperature, using pure hydrogen plasma, the power is set to 50W, the flow rate is 100SCCM, the pressure is 600Pa, and the etching time is 5 minutes. During the etching process, a vacuum pump is used to keep the cav...

Embodiment 2

[0063] The method for preparing the graphene strips with neat edges in the present embodiment may further comprise the steps:

[0064] (1) The substrate material is a silicon wafer with 100nm silicon dioxide grown by thermal oxidation, and the graphene is migrated after the substrate is cleaned.

[0065] (2) Ordinary lithography or electron beam lithography, glue the sample with graphene migrated on the substrate, and then use photolithography or electron beam lithography to expose the required graphics. The size of the graphics can be in nanoscale or in micron scale.

[0066] (3) Growth of the metal film: Magnesium with a thickness of 1 nm was grown on the sample after photolithography and development by using magnetron sputtering.

[0067] (4) Hydrogen plasma etching: at room temperature, using pure hydrogen plasma, the power is set to 100W, the flow rate is 10SCCM, the pressure is 60Pa, and the etching time is 60 minutes. During the etching process, a vacuum pump is used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com