NaY type molecular sieve and preparation method thereof

A molecular sieve and micro-reactor technology, applied in the direction of octahedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problem of large molecular sieve grains, achieve large specific surface area, complete crystal grains, and high crystallinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

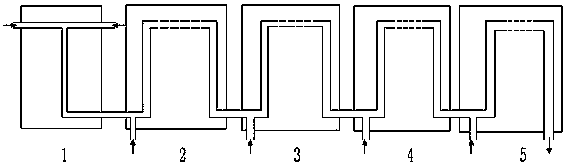

Method used

Image

Examples

Embodiment 1

[0055] Preparation of guiding agent: Dissolve 8g of sodium hydroxide solid in 80g of water, add 2.5g of sodium metaaluminate (Al 2 o 3 Content is 45wt%, Na 2 O content is 41wt%), then add 40g water glass (SiO 2 The content is 28wt%, Na 2 The O content is 8wt%), mixed evenly, and aged at 18°C for 4 hours to prepare the directing agent.

[0056] NaAlO with a concentration of 30g / 100mL 2 with 135g / 100ml of Na 2 SiO 3 mixed solution and 50g / 100mL of Al 2 (SO 4 ) 3 Add the mixed solution of the solution and 180g / 100ml silicic acid solution into the respective component tanks, put each raw material tank, the first impingement flow microreactor and other microreactors into the oil bath, put the raw material tank and the second Heat the first impingement flow reactor to 90°C, turn on the booster pumps of the two component tanks, and simultaneously enter the alkaline solution and the acidic solution into the first impingement flow reactor through the atomizer, and control th...

Embodiment 2

[0058] Preparation of guiding agent: Dissolve 10g of sodium hydroxide solid in 90g of water, add 3g of sodium metaaluminate (Al 2 o 3 Content is 45wt%, Na 2 O content is 41wt%), then add 50g water glass (SiO 2 The content is 28wt%, Na 2 O content is 8wt%), mixed evenly and aged at 20°C for 3h to prepare the directing agent.

[0059] NaAlO with a concentration of 20g / 100mL2 with 120g / 100ml of Na 2 SiO 3 mixed solution and 20g / 100mL of Al 2 (SO 4 ) 3 Add the mixed solution of the solution and 145g / 100ml silicic acid solution into the respective component tanks, put each raw material tank, the first impingement flow microreactor and other microreactors into the oil bath, put the raw material tank and the second Heat the first impingement flow reactor to 110°C, turn on the booster pumps of the two component tanks, and simultaneously enter the alkaline solution and the acidic solution into the first impingement flow reactor through the atomizer, and control the flow rate of...

Embodiment 3

[0061] Preparation of guiding agent: Dissolve 10g of sodium hydroxide solid in 90g of water, add 3g of sodium metaaluminate (Al 2 o 3 Content is 45wt%, Na 2 O content is 41wt%), then add 50g water glass (SiO 2 The content is 28wt%, Na 2 O content is 8wt%), mixed evenly and aged at 20°C for 3h to prepare the directing agent.

[0062] NaAlO with a concentration of 20g / 100mL 2 With 130g / 100ml of Na 2 SiO 3 mixed solution and 20g / 100mL of Al 2 (SO 4 ) 3 The mixed solution of the solution and 120g / 100ml silicic acid solution is added to the respective component tanks, each raw material tank, the first impingement flow microreactor and other microreactors are put into the oil bath, the raw material tank and the second Heat the first impingement flow reactor to 120°C, turn on the booster pumps of the two component tanks, and simultaneously enter the alkaline solution and the acidic solution into the first impingement flow reactor through the atomizer, and control the flow ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com