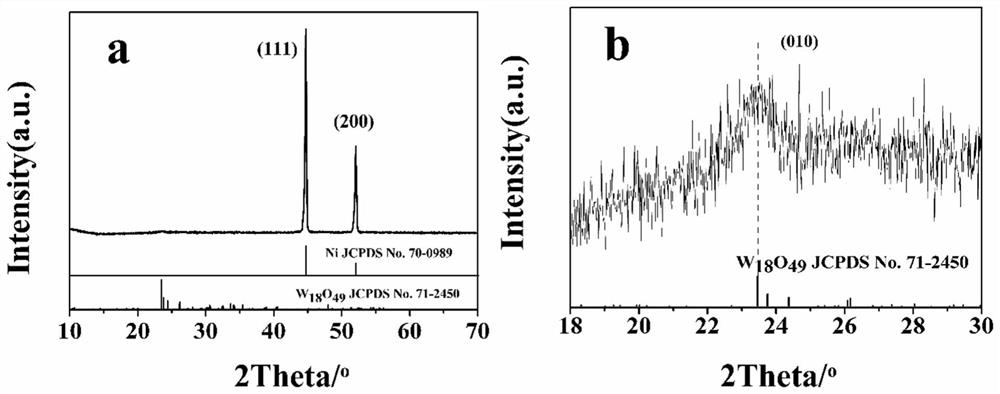

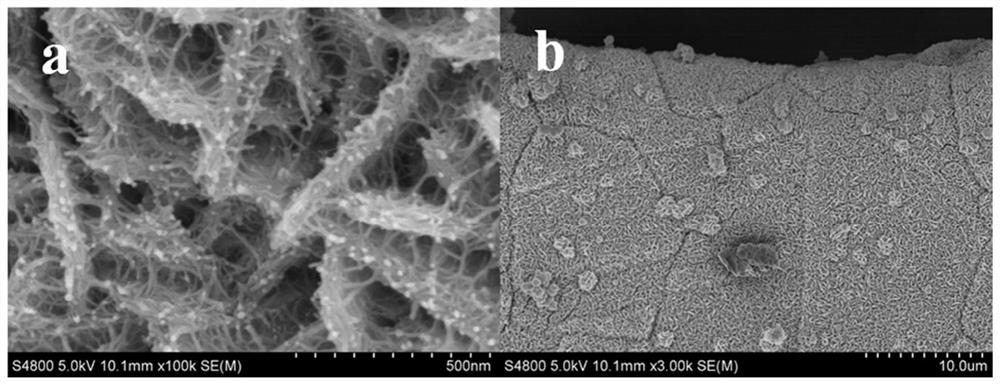

a w 18 o 49 Preparation method of /nf self-supporting electrocatalytic material

An electrocatalytic material and self-supporting technology, applied in the field of composite materials, can solve problems such as the influence of nanomaterials on electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Add WCl 6 Add a volume ratio of absolute ethanol: isopropanol: n-butanol = 1:1:1 mixed alcohol to make a 0.05mol / L solution A;

[0031] 2) Add analytically pure ethylenediamine and cycloheptylamine to solution A, so that ethylenediamine, cycloheptylamine and WCl 6 The ratio of the amount of the substances is 0.5:0.5:1 to obtain solution B, seal solution B with plastic wrap, then magnetically stir for 30 minutes, and ultrasonically treat for 5 minutes to obtain uniformly mixed solution B;

[0032] 3) first immerse the foamed nickel with a length of 7cm and a width of 1cm in acetone for 30 minutes, then place the processed nickel foam in a 3mol / L HCl solution for 30 minutes, then use pure water for 30 minutes, and finally Then place it in absolute ethanol for 30 minutes of ultrasonic treatment, and continue to rinse with absolute ethanol for 3 times;

[0033] 4) Pour solution B into a polytetrafluoroethylene-lined autoclave according to a volume filling ratio of 40%,...

Embodiment 2

[0039] 1) Will W(CO) 6 Add a volume ratio of absolute ethanol: isopropanol: n-butanol = 1:0.3:0.2 mixed alcohol to make a 0.03mol / L solution A;

[0040] 2) Add analytically pure ethylenediamine and cycloheptylamine to solution A, so that ethylenediamine, cycloheptylamine and W(CO) 6The ratio of the amount of the substance is 0.2:0.1:1 to obtain solution B, seal solution B with plastic wrap, then magnetically stir for 30 minutes, and ultrasonically treat for 10 minutes to obtain uniformly mixed solution B;

[0041] 3) first immerse the nickel foam with a length of 7 cm and a width of 1 cm in acetone for 20 minutes, then place the processed nickel foam in a 3 mol / L HCl solution for 20 minutes, then use pure water for 30 minutes, and finally Then place it in absolute ethanol for ultrasonic treatment for 30 minutes, and continue to rinse with absolute ethanol for 5 times;

[0042] 4) Pour solution B into a polytetrafluoroethylene-lined autoclave according to a volume filling rat...

Embodiment 3

[0047] 1) Add WCl 6 Add a volume ratio of absolute ethanol: isopropanol: n-butanol = 1:0.5:0.5 mixed alcohol to make a 0.03mol / L solution A;

[0048] 2) Add analytically pure ethylenediamine and cycloheptylamine to solution A, so that ethylenediamine, cycloheptylamine and WCl 6 The ratio of the amount of the substance is 0.3:0.3:1 to obtain solution B, seal solution B with plastic wrap, then magnetically stir for 25 minutes, and ultrasonically treat for 5 minutes to obtain uniformly mixed solution B;

[0049] 3) first immerse the foamed nickel with a length of 6cm and a width of 1cm in acetone for 25 minutes, then place the processed nickel foam in a 4mol / L HCl solution for 25 minutes, then use pure water for 30 minutes, and finally Then place it in absolute ethanol for ultrasonic treatment for 25 minutes, and continue to rinse with absolute ethanol for 3 times;

[0050] 4) Pour solution B into a polytetrafluoroethylene-lined autoclave according to a volume filling ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com