Concrete stone imitation brick and method for preparing same

A stone brick and concrete technology, applied in the field of building materials, can solve the problems of natural stone quality constraints, poor weather resistance, and impact on the ecological environment, and achieve high production efficiency, good weather resistance, and less pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

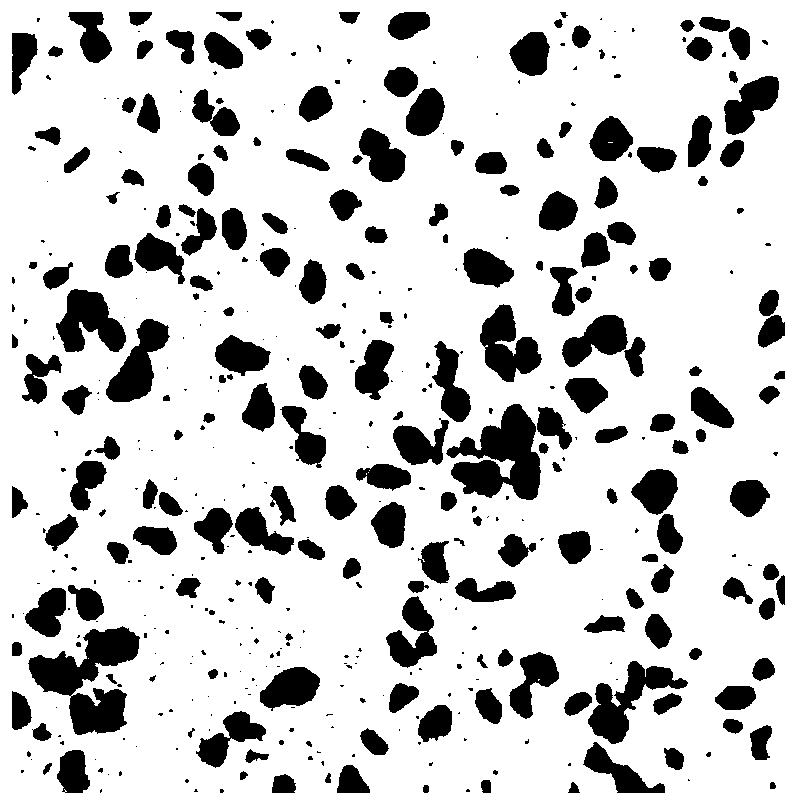

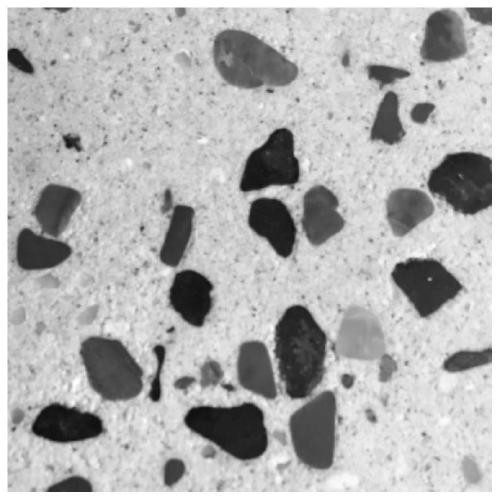

Image

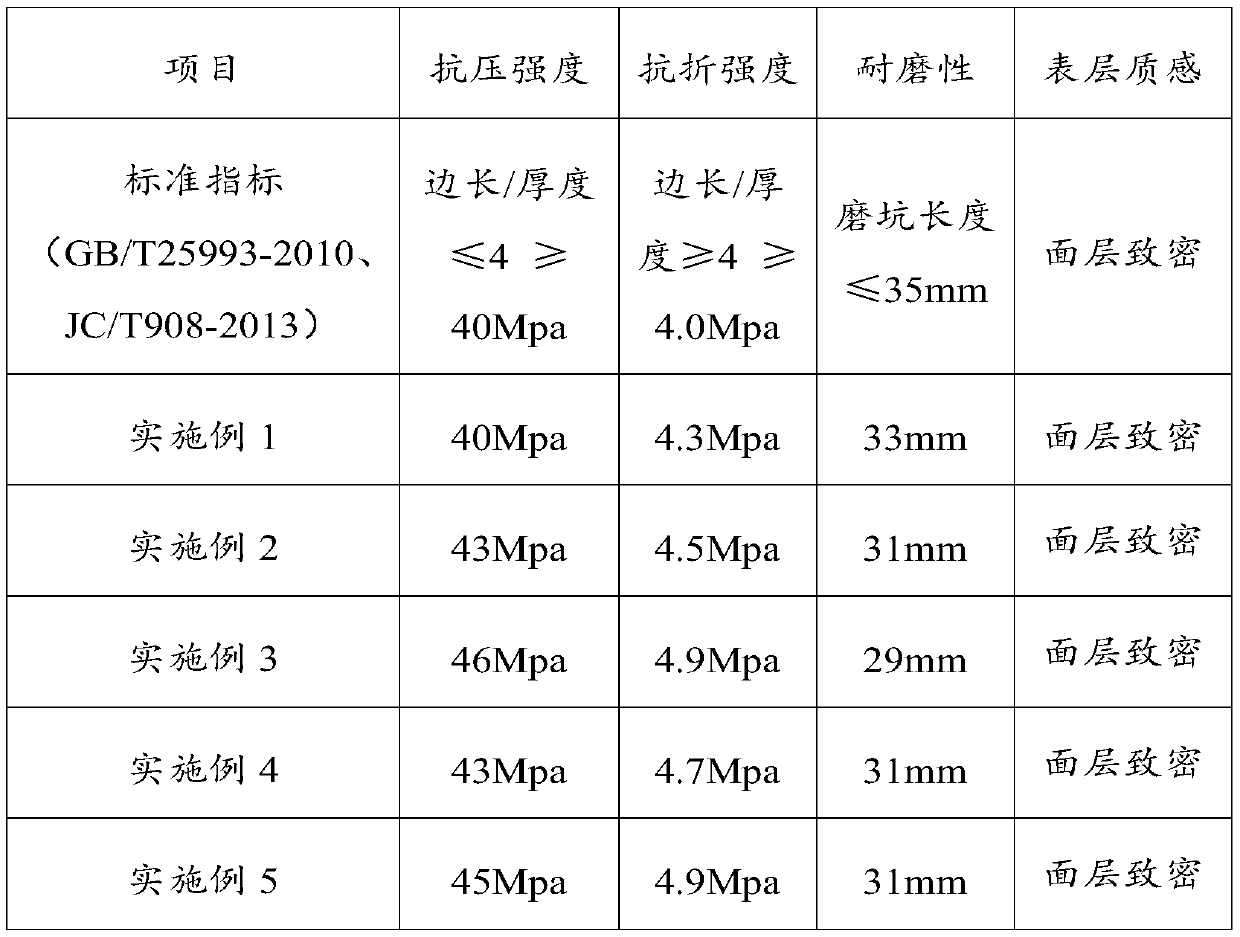

Examples

preparation example Construction

[0024] In addition, the application also provides a method for preparing concrete imitation stone bricks, which specifically includes the following steps:

[0025] S1, stirring.

[0026] Weigh each component material of the base layer, place it in a stirrer, and stir evenly; put each component material of the surface layer together in a surface layer stirrer, and stir evenly.

[0027] S2. After mixing the components of the base layer, place the cloth on the bottom of the mold, press the pressure head slightly, and leave a space about 10mm deep on the upper part of the mold frame.

[0028] S3. Mix the components of the surface layer and fill the reserved space of the mold frame so that they are located on the surface of the base layer. The mold head presses down, vibrates and presses to form, and then demoulds.

[0029] S4. Bricks enter the curing kiln for 24 hours of steam curing or 28 days of room temperature curing.

[0030] S5. The brick body is taken out of the kiln, and...

Embodiment 1

[0035] A concrete imitation stone brick, comprising a surface layer and a base layer, the raw materials of the base layer are as follows: 10 kg of machine-made sand, 40 kg of the first crushed stone with a particle size of 3-5 mm, 15 kg of the second crushed stone with a particle size of 6-10 mm, 20 kg of cement, water 5.4kg and 0.18kg of water reducing agent. Surface raw materials are as follows: 1kg of 10-20mesh quartz sand, 2.5kg of 20-40mesh quartz sand, 7.5kg of 40-80mesh quartz sand, 35kg of 80-120mesh quartz sand, 23kg of Portland cement PO52.5, grain 15kg of colored stones with a diameter less than 5mm, 6.4kg of water, and 0.25kg of polycarboxylate superplasticizer (the water-cement ratio is 0.28).

[0036] The preparation method of the present embodiment is as follows:

[0037] (1) Weigh each component material of the base layer, place it in a stirrer, and stir evenly; place each component material of the surface layer of the material together in a surface layer stir...

Embodiment 2

[0044]A concrete imitation stone brick, comprising a surface layer and a base layer, the raw materials of the base layer are as follows: 10 kg of machine-made sand, 40 kg of the first crushed stone with a particle size of 3-5 mm, 15 kg of the second crushed stone with a particle size of 6-10 mm, 20 kg of cement, water 5.4kg and 0.18kg of water reducing agent. Surface materials are as follows: 0.8kg of aeolian sand of 10-20 mesh, 2kg of aeolian sand of 20-40 mesh, 6kg of aeolian sand of 40-80 mesh, 40kg of aeolian sand of 80-120 mesh, Portland cement PO52.5 23kg, 20kg of colored stones, 6.4kg of water and 0.25kg of polycarboxylate superplasticizer (the water-cement ratio is 0.28).

[0045] The preparation method of the present embodiment is as follows:

[0046] (1) Weigh each component material of the base layer, place it in a stirrer, and stir evenly; place each component material of the surface layer of the material together in a surface layer stirrer, and stir evenly.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com