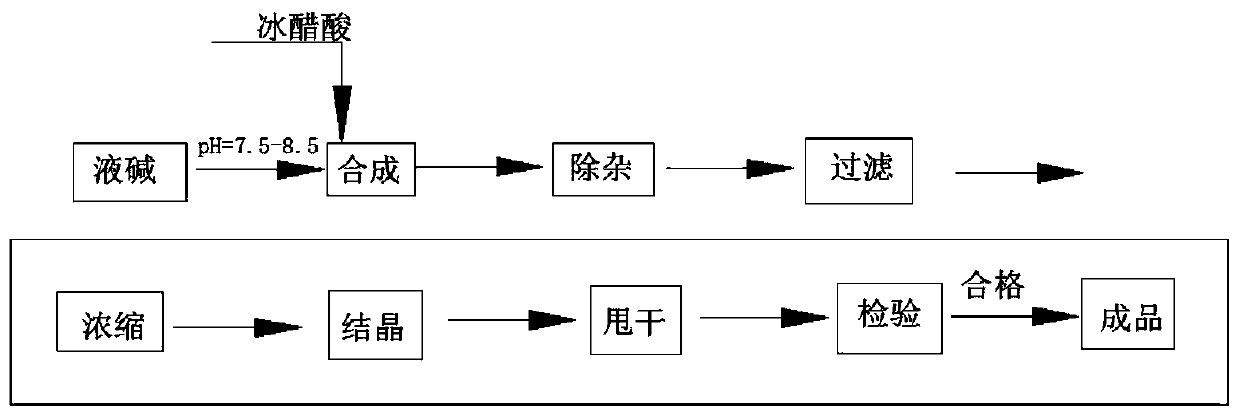

A kind of sodium acetate production process

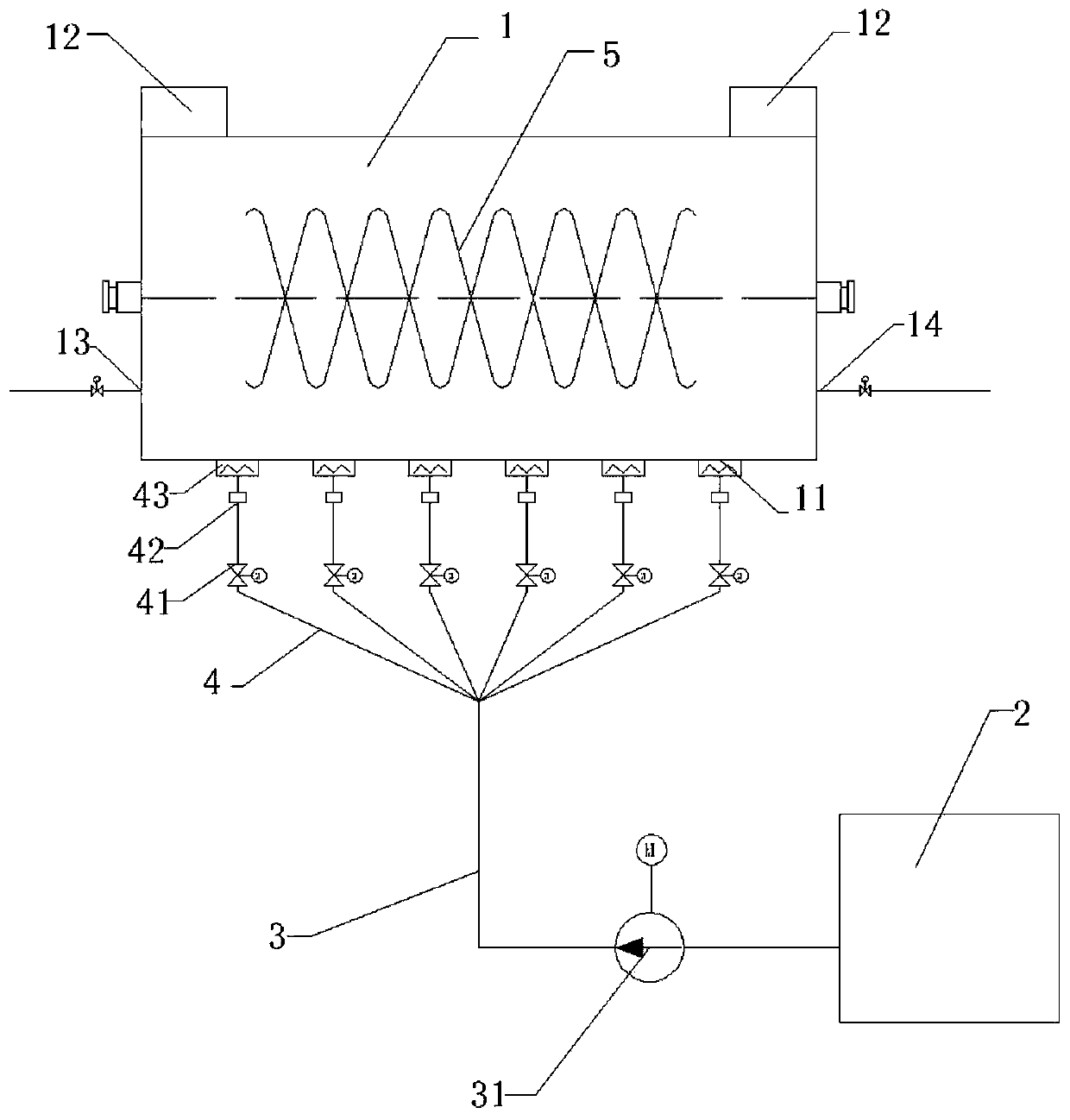

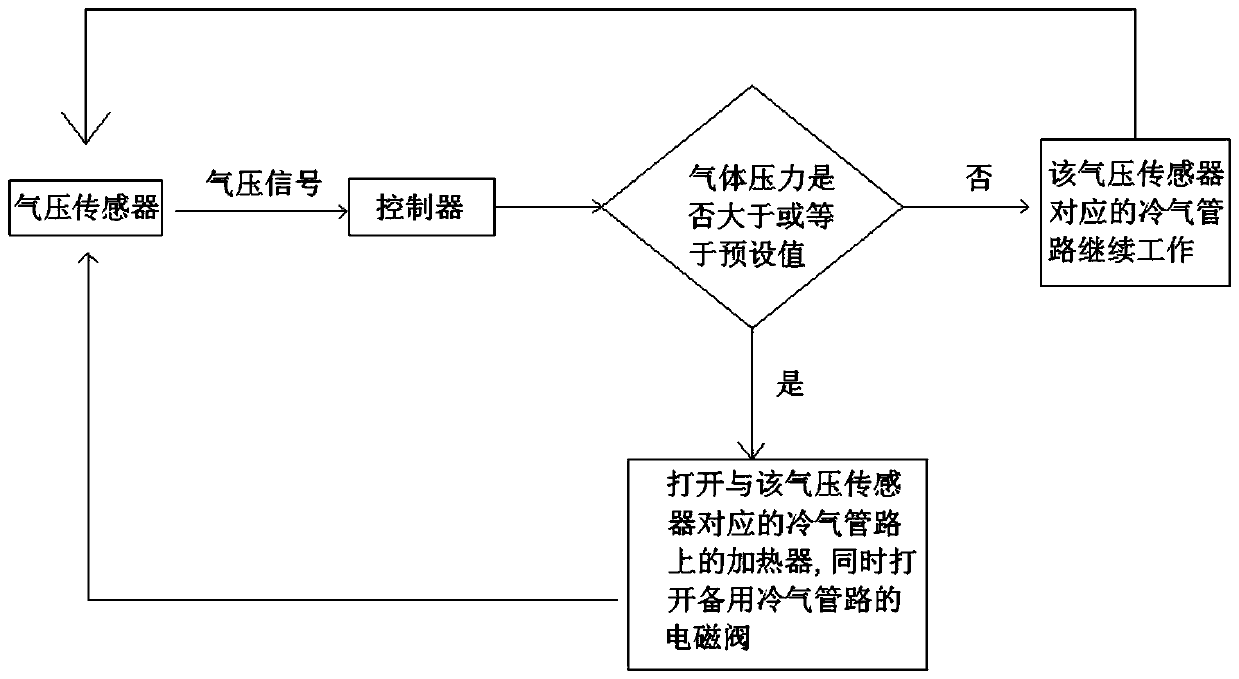

A production process, sodium acetate technology, applied in carboxylate preparation, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of freezing or crystallization blocking the gas outlet, reduced efficiency, poor effect, etc., to achieve easy Automatic operation and control, good cooling efficiency, and simple crystallization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Put glacial acetic acid and sodium hydroxide solution with a mass fraction of 32% into the reaction kettle with a mass ratio of 1:1, raise the temperature in the kettle to 85 degrees, and keep the temperature constant for reaction; check the pH of the solution at any time, When the reaction reaches a pH value equal to 7.5, add a heavy metal ion precipitant and activated carbon in sequence, decolorize and filter, and retain the filtrate; the heavy metal ion precipitant can be selected from sodium sulfide or a commercially available heavy metal ion precipitant. The filtrate is concentrated by evaporation until the concentration of the sodium acetate solution is 30Bé to obtain a concentrated solution, and then the concentrated solution is passed into the crystallization device of the present invention, and the crystallization device is then cooled to crystallize, so that the temperature in the crystallization device is reduced to 45 degrees; The feed liquid is centrifuged a...

Embodiment 2

[0049] Put glacial acetic acid and sodium hydroxide solution with a mass fraction of 32%-35% into the reaction kettle at a material ratio of 1.05:1, raise the temperature in the kettle to 88 degrees, and keep the temperature constant for reaction; detect the solution at any time When reacting to a pH value equal to 8.0, add heavy metal ion precipitant and active carbon respectively in sequence, decolorize and filter, and retain filtrate; heavy metal ion precipitant can be selected from sodium sulfide or commercially available heavy metal ion precipitant. The filtrate is concentrated by evaporation until the concentration of the sodium acetate solution is 28Bé to obtain a concentrated solution, and then the concentrated solution is passed into the crystallization device of the present invention, and the crystallization device is then cooled to crystallize, so that the temperature in the crystallization device is reduced to 42 degrees; The feed liquid is centrifuged and dried to ...

Embodiment 3

[0055] Put glacial acetic acid and sodium hydroxide solution with a mass fraction of 35% into the reaction kettle with a mass ratio of 1.08:1, raise the temperature in the kettle to 90 degrees, and keep the temperature constant for reaction; check the pH of the solution at any time, When the reaction reaches a pH value equal to 8.3, add a heavy metal ion precipitant and activated carbon in sequence, decolorize and filter, and retain the filtrate; the heavy metal ion precipitant can be selected from sodium sulfide or a commercially available heavy metal ion precipitant. The filtrate is concentrated by evaporation until the concentration of the sodium acetate solution is 26Bé to obtain a concentrated solution, and then the concentrated solution is passed into the crystallization device of the present invention, and the crystallization device is then cooled to crystallize, so that the temperature in the crystallization device is reduced to 40 degrees; The feed liquid is centrifuge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| enthalpy of fusion | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com