Glue composition, quantum dot glue, quantum dot composite material, quantum dot device

A composite material and quantum dot technology, applied in the fields of quantum dot glue, quantum dot devices, and quantum dot composite materials, can solve the problems of decreased efficiency of quantum dots, poor oxygen barrier performance, insufficient supply, etc., so as to improve the water and oxygen barrier properties, Improve the effect of large black borders and reduce efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

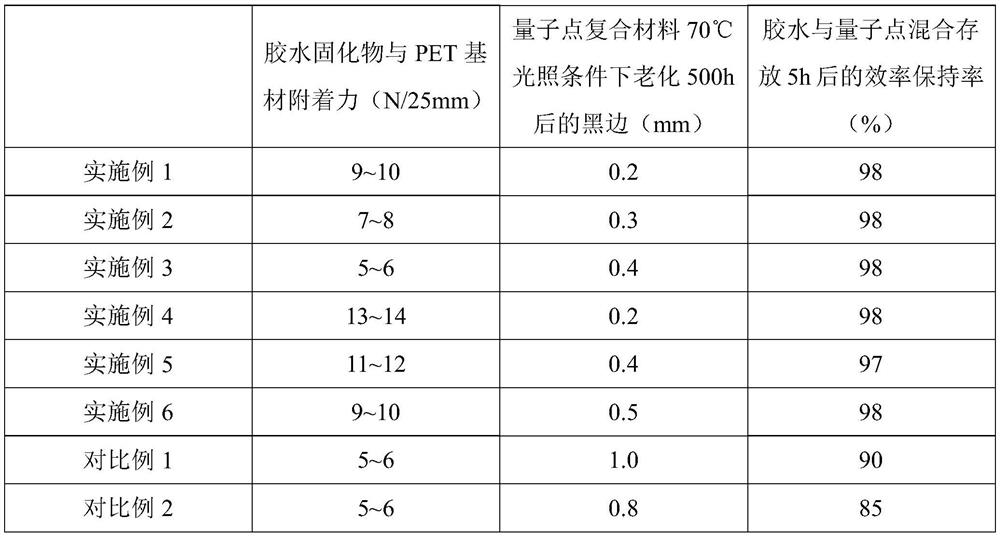

Examples

preparation example Construction

[0052] The present invention also provides the preparation method of above-mentioned glue composition, comprises the following steps:

[0053] S1, uniformly disperse the block copolymer in the first acrylate monomer to obtain a mixture, the block copolymer includes a middle block and a first block and a second block connected at both ends of the middle block , the middle block is a soft segment, and the first block and the second block are rigid segments;

[0054] S2, add the first acrylate monomer and the second acrylate monomer to the above mixture to adjust the viscosity, then add the curing agent, mix well, the second acrylate monomer is a difunctional acrylate monomer and / or multifunctional acrylate monomers.

[0055] In some embodiments, the monomer of the above-mentioned middle block is an alkene compound, the monomer of the first block is an aromatic hydrocarbon containing a carbon-carbon double bond or a nitrile compound containing a carbon-carbon double bond, and th...

Embodiment 1

[0065] In a three-necked flask, the block copolymer SIS (relative molecular mass: 150,000, rigid segment ratio 15%) was added to isobornyl acrylate, wherein the mass fraction of SIS was 30%, the temperature was raised to 60°C, and stirred Increase the speed to 500-800rmp, stir for 1-1.5h, until the block copolymer is completely dissolved, the solution appears clear and transparent, and the preparation of the block copolymer solution is completed.

[0066] Get 50 mass parts of the above-mentioned block copolymer solution, add 40 mass parts of isobornyl acrylate, 10 mass parts of dipropylene glycol diacrylate (difunctional acrylate monomer), add 3 mass parts of 2 simultaneously, 4,6-trimethylbenzoyl-diphenylphosphine oxide (curing agent), mix evenly, the solution is clear and transparent, and the glue preparation is completed.

Embodiment 2

[0068]In a three-necked flask, the block copolymer SIS (relative molecular mass: 150,000, rigid segment ratio 30%) was added to isobornyl acrylate, wherein the mass fraction of SIS was 30%, the temperature was raised to 60°C, and stirred Increase the speed to 500-800rmp, stir for 1-1.5h, until the block copolymer is completely dissolved, the solution appears clear and transparent, and the preparation of the block copolymer solution is completed.

[0069] Get 50 mass parts of the above-mentioned block copolymer solution, add 40 mass parts of isobornyl acrylate, 10 mass parts of dipropylene glycol diacrylate (difunctional acrylate monomer), add 3 mass parts of 2 simultaneously, 4,6-trimethylbenzoyl-diphenylphosphine oxide (curing agent), mix evenly, the solution is clear and transparent, and the glue preparation is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com