Anti-pilling overcoat and treatment process thereof

An anti-pilling and anti-pilling agent technology, applied in the field of clothing, can solve problems such as not easy to pilling, and achieve the effects of reducing tangling and pilling, preventing and tangling and pilling, and improving anti-pilling and pilling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

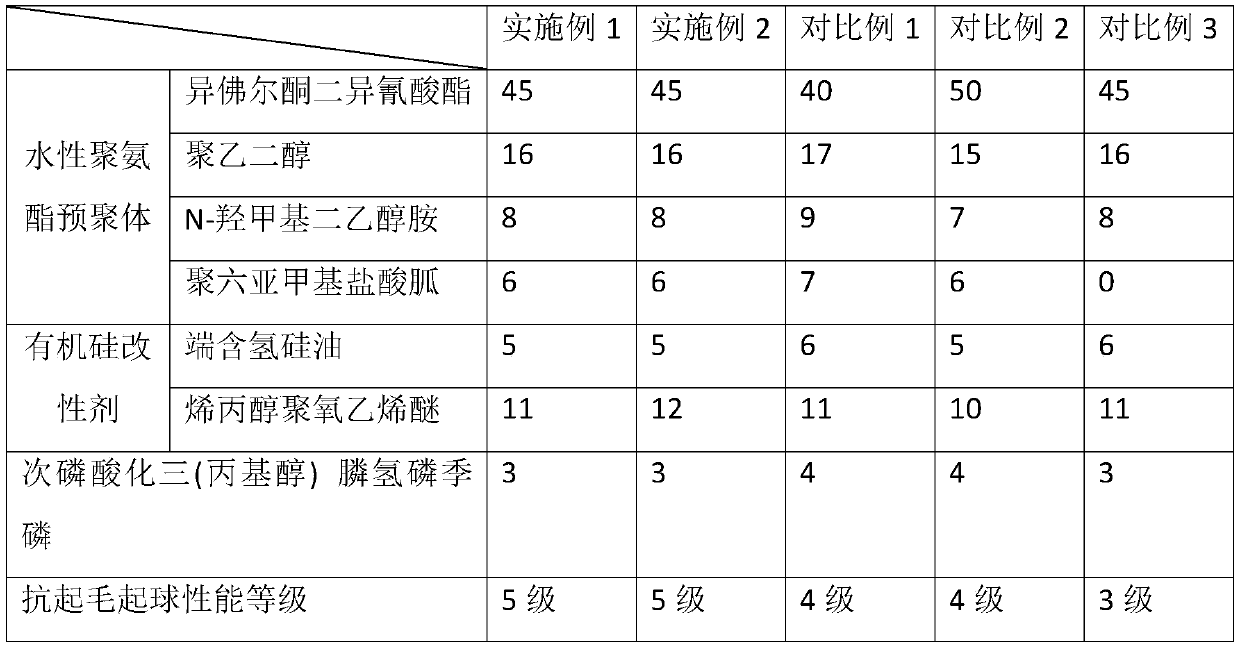

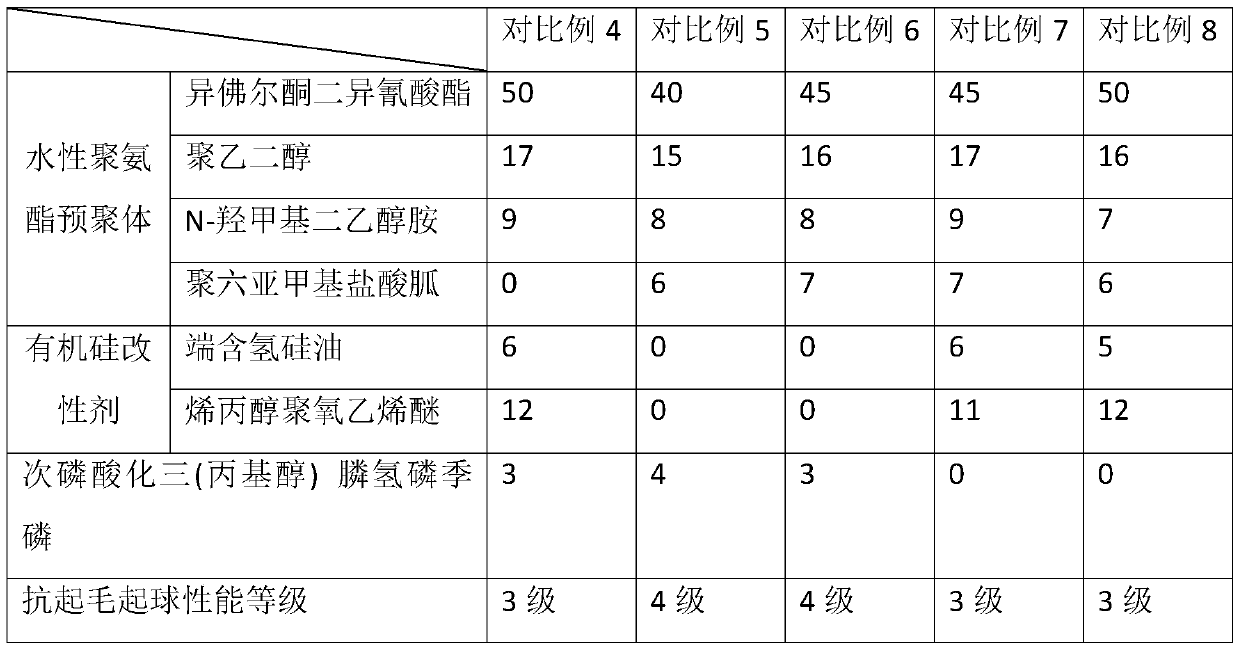

[0044] An anti-pilling coat comprises a coat body, the raw material of which is obtained through anti-pilling agent treatment. In parts by weight, the raw material components of the anti-pilling agent are shown in Table 1.

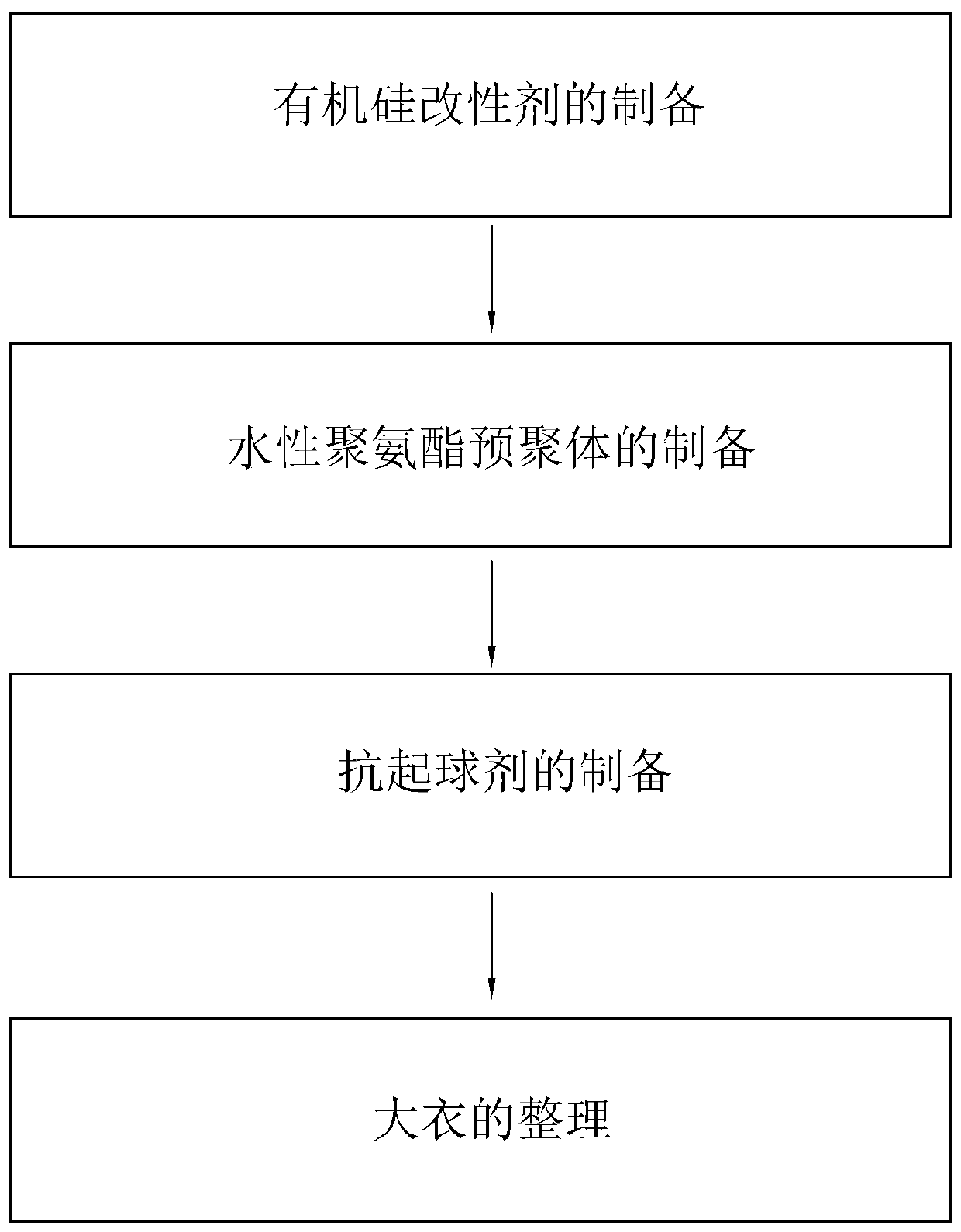

[0045] The treatment process of coat material includes the following steps:

[0046]Step 1, the preparation of silicone modifier: Stir the metered hydrogen-containing silicone oil and allyl alcohol polyoxyethylene ether evenly, add chloroplatinic acid after heating up to 80°C, and pass through nitrogen protection, and then heat up to 90- 100°C, keep warm for 4-5h and remove water to obtain silicone modifier;

[0047] Step 2, the preparation of water-based polyurethane prepolymer: add dibutyltin dilaurate to the measured polyethylene glycol, heat up to 70°C and pass nitrogen protection, add measured isophorone diisocyanate and keep it warm for 1-2h, Then add N-methyloldiethanolamine and keep it warm for 1-2 hours, lower the system temperature to 15-20°C, ...

Embodiment 2

[0051] The difference from Example 1 is that, in parts by weight, the raw materials of the anti-pilling agent are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com