Preparation method of hollow fiber double phase composite ceramic oxygen permeable membrane

A technology of composite ceramics and oxygen-permeable membranes, applied in separation methods, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem of low oxygen permeation flux of oxygen-permeable membranes, and achieve oxygen exchange entropy change and exchange enthalpy change Low, surface exchange coefficient increased, the effect of uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

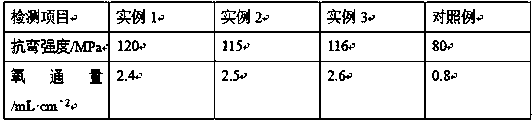

example 1

[0035] Add polyether alum and polyvinylpyrrolidone to N-methylpyrrolidone, stir at 150r / min at room temperature for 6h to obtain an organic solution; heat the biphasic composite powder into the organic solution, and stir at 400r / min at room temperature for 22h , to obtain the casting solution; 2 / 3 of the casting solution was added to the slurry tank, and vacuum degassed for 30 minutes. Under nitrogen pressure, the casting solution passed through the spinneret to obtain a hollow fiber membrane green body; Soak the blank in deionized water for 46 hours, cut it, and dry it in the air for 12 hours to obtain a solidified hollow fiber membrane green body; immerse one end of the solidified hollow fiber membrane green body in 1 / 3 of the casting solution, take it out Soak in deionized water for 12 hours, and dry at room temperature for 10 hours to obtain a green hollow fiber membrane with one end sealed; place the hollow fiber membrane green body with one end sealed in a sintering furna...

example 2

[0037] Add polyether alum and polyvinylpyrrolidone into N-methylpyrrolidone, stir at 175r / min at room temperature for 7h to obtain an organic solution; heat the biphasic composite powder into the organic solution, and stir at 450r / min at room temperature for 23h , to obtain the casting solution; 2 / 3 of the casting solution was added to the slurry tank, and vacuum degassed for 35 minutes. Under nitrogen pressure, the casting solution passed through the spinneret to obtain a hollow fiber membrane green body; Soak the blank in deionized water for 47 hours, cut it, and dry it in the air for 14 hours to obtain a solidified hollow fiber membrane green body; immerse one end of the solidified hollow fiber membrane green body in 1 / 3 of the casting solution, take it out Soak in deionized water for 14 hours, dry at room temperature for 11 hours to obtain a hollow fiber membrane green body with one end sealed; place the hollow fiber membrane green body with one end sealed in a sintering fu...

example 3

[0039] Add polyether alum and polyvinylpyrrolidone to N-methylpyrrolidone, and stir at 200r / min at room temperature for 8h to obtain an organic solution; heat the biphasic composite powder into the organic solution, and stir at room temperature at 500r / min for 24h , to obtain the casting solution; 2 / 3 of the casting solution was added to the slurry tank, and vacuum degassed for 40 minutes. Under nitrogen pressure, the casting solution passed through the spinneret to obtain a hollow fiber membrane green body; the hollow fiber membrane Soak the blank in deionized water for 48 hours, cut it, and dry it in the air for 16 hours to obtain a solidified hollow fiber membrane green body; immerse one end of the solidified hollow fiber membrane green body in 1 / 3 of the casting solution, take it out Soak in deionized water for 16 hours, and dry at room temperature for 12 hours to obtain a hollow fiber membrane green body with one end sealed; place the hollow fiber membrane green body with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com