Purification method of degarelix

A purification method, the technology of degarelix, applied in the preparation method of peptides, chemical instruments and methods, organic chemistry, etc., can solve the problems of reducing the life of the packing and column efficiency, causing great damage to the packing, and affecting the stability of the purification process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

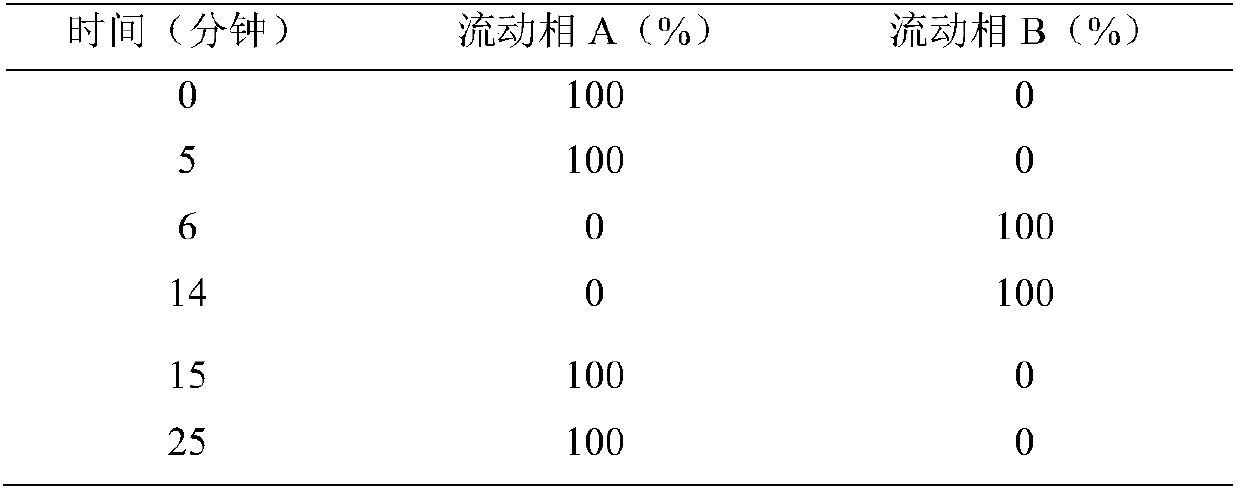

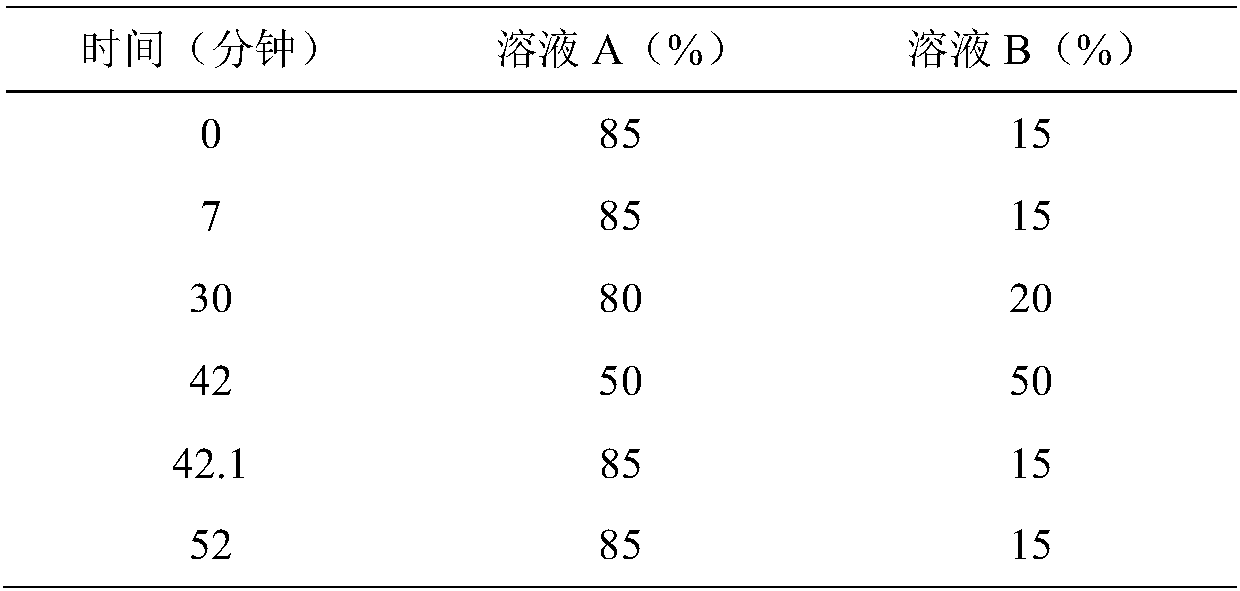

Method used

Image

Examples

Embodiment 1

[0084] Example 1 Cleavage and Precipitation of Degarelix Resin Peptide

[0085] Under stirring, slowly add 1.37kg of solid-phase synthesized degarelix resin peptide into 6.85L of pre-cooled (about 0°C) trifluoroacetic acid, heat to 40°C, stir for 2.5 hours, and the cracking ends. Pump the lysate into a concentration tank, wash the resin with 3×0.8L trifluoroacetic acid, combine the washing liquid and the lysate, and concentrate under reduced pressure at 25-30°C to about 3.0L. Under stirring, slowly add the concentrated solution into 18L of isopropyl ether (pre-cooled below 0°C), and wash the concentration tank with 0.5L of trifluoroacetic acid, suction filter after the addition, and beat the filter cake with 3×3L of isopropyl ether. Drain the wet product and store it in refrigerator.

[0086] Repeat the above operations to carry out the second small batch of cleavage and precipitation, combine the two small batches of wet products, beat with 6L isopropyl ether, filter with su...

Embodiment 2

[0087] Embodiment 2 sodium carbonate method removes trifluoroacetic acid

[0088] Na 2 CO 3 The configuration of the aqueous solution: 504gNa 2 CO 3 Add it into 1.8L of purified water, stir and dissolve at 35°C and set aside.

[0089] At 25°C, add 1.8kg of the product prepared in Example 1 into a mixed solvent of 18L methanol and 1.8L purified water, stir and dissolve, then add Na 2 CO 3 The aqueous solution was added dropwise in 10 minutes. After stirring and reacting for 0.5 h, 9 L of acetone was added, and the stirring was continued for 15 min, followed by suction filtration and rinsed with 9 L of acetone. The filter cake was beaten with 36L of acetone for 1 hour, filtered, rinsed with 9L of acetone, and then dried under reduced pressure at 25°C for 12 hours to obtain 1.08kg of crude degarelix, with a purity of 97.22% and a trifluoroacetic acid content of 1.70%. .

Embodiment 3

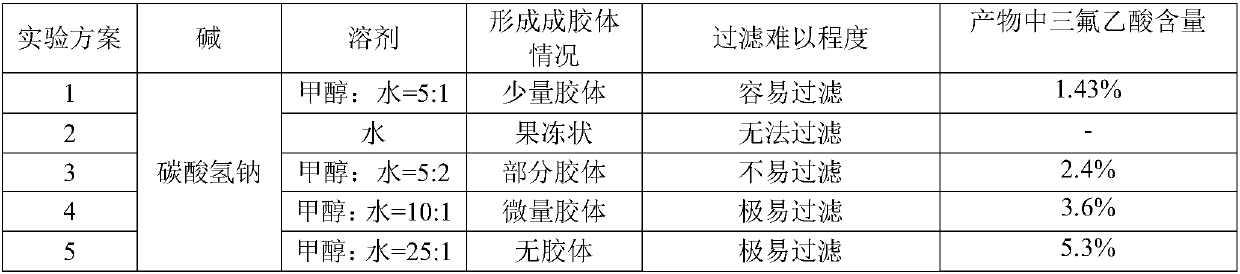

[0090] Embodiment 3 sodium bicarbonate method removes trifluoroacetic acid

[0091] plan 1

[0092] NaHCO 3 The configuration of the aqueous solution: 424.4g NaHCO 3 Add it to 4.86L of purified water, stir and dissolve at 40°C for later use.

[0093] Add 1.8kg of the product prepared according to Example 1 into a mixed solvent of 32.4L methanol and 1.62L purified water at 30-35°C, stir for about 30min to dissolve, then add NaHCO dropwise 3 The aqueous solution was added dropwise in about 15 minutes. After stirring and reacting for 2 hours, 16.2 L of acetone was added, and the stirring was continued for 15 minutes, followed by suction filtration and rinsed with 3.6 L of acetone. The filter cake was beaten with a solution of 16.2L acetone and acetic acid for 30 minutes, filtered, rinsed with 3.6L acetone and drained, and then beaten with 18L isopropyl ether. After filtration, the filter cake was dried under reduced pressure at 30°C for 12 hours to obtain 1.2kg ground The cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com