Photo-oxygen and biodegradable plastic containing bio-based material and preparation method thereof

A biodegradable and biodegradable technology, applied in the field of photooxygen containing bio-based materials, biodegradable plastics and their preparation, can solve the problem that degradable plastics are difficult to recycle, visual pollution cannot be completely eliminated, and mildew of distiller's grains cannot be solved to achieve rapid and complete degradation, high economic benefits and social value, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of embodiment 1 dried distiller's grains pretreatment

[0034] Add 3 times its weight volume fraction to fresh distiller's grains and be 75% ethanol solution, leave standstill at room temperature for 6h to carry out degreasing treatment, filter, remove filtrate, then add the NaOH solution that the mass concentration of 4 times of filter residue weight is 5%, at room temperature Soak for 24 hours for deproteinization, then wash with water until the pH is neutral, and dry until the water content is 5-10% m / m to obtain the pretreated distiller's grains.

Embodiment 2

[0035] The preparation of embodiment 2 mugwort wax

[0036] Take fresh Artemisia argyi leaves, crush them and pack them into a column, then use cyclohexane to circulate and elute the packed medicinal material column. After the liquid comes out, measure the flow rate of the effluent liquid, and after circularly eluting 5BV, connect a silica gel column for adsorption , after continuing to circulate and elute 3BV, remove the medicinal material column, empty the cyclohexane in the medicinal material column with an air pump, and load the cyclohexane into the silica gel column for adsorption; finally take another cyclohexane to wash the wax in the silica gel column After the color of the eluted eluent becomes lighter, empty the cyclohexane in the column with an air pump, merge with the eluent, and recover the cyclohexane with a rotary evaporator to obtain the mugwort wax.

Embodiment 3

[0037] The preparation of embodiment 3 bio-based composites

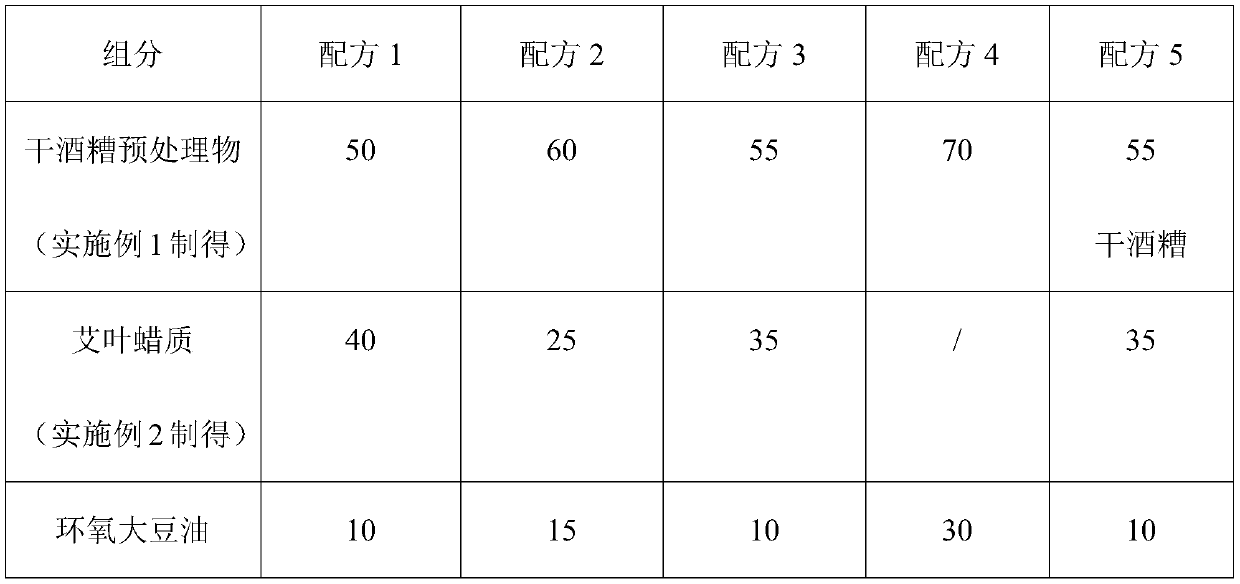

[0038] The bio-based composite of the present embodiment includes the components in weight percent shown in the table below:

[0039]

[0040] The dried distiller's grains in the above formula 5 is a material with a water content of 5-10% m / m obtained by direct drying of fresh distiller's grains, without degreasing and deproteinizing treatment before drying. The fresh distiller's grains are fresh distiller's grains directly recovered from breweries without any treatment.

[0041] The preparation steps of the bio-based composite of formula 1-3: blend and pulverize the dried distiller’s grain pretreatment and mugwort leaf wax to obtain a composite powder, then add epoxy soybean oil, mix well, and heat press for 5 minutes under a hot press , after cooling to 50°C, the pressure is released, and the bio-based composite is obtained.

[0042] The preparation steps of the bio-based composites of formulations 4-5 refer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com