Polycarbonate (PC) and polybutylene terephthalate (PBT) composite material resistant to low temperature impact and preparation process thereof

A composite material and low temperature resistance technology, applied in the field of engineering plastics, can solve the problems of poor corrosion resistance and antibacterial properties, low temperature resistance and impact resistance, etc., and achieve the effect of improving corrosion resistance and antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

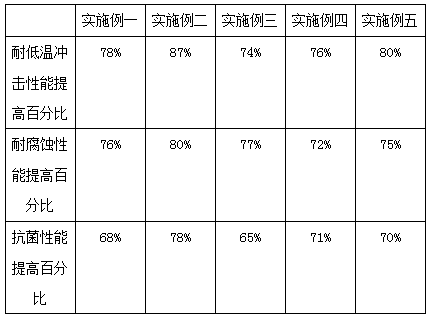

Examples

Embodiment 1

[0023] Propose a kind of low-temperature impact-resistant PC and PBT composite material in the present embodiment, comprise the raw material of following parts by weight: PC resin 16 parts, PBT resin 12 parts, polyvinyl chloride 10 parts, plasticizer 13 parts, calcium carbonate 12 parts , 7 parts of butyl benzyl phthalate, 16 parts of micron SiO2 powder, 24 parts of sodium hexametaphosphate, 9 parts of sodium alginate, 11 parts of surfactant, 23 parts of dioctyl terephthalate, 7 parts of kaolin 14 parts of quartz sand, 19 parts of antimony trioxide, 9 parts of alumina powder, 28 parts of talcum powder, 19 parts of silicate carrier, 11 parts of nano-silver antibacterial agent and appropriate amount of water;

[0024] Its preparation method comprises the following steps:

[0025] S1: Add PC resin, PBT resin, polyvinyl chloride, plasticizer, calcium carbonate, butyl benzyl phthalate and micron-sized SiO2 powder into the stirring tank for a stirring process until the stirring is u...

Embodiment 2

[0032] Propose a kind of low temperature impact resistance PC and PBT composite material in the present embodiment, comprise the raw material of following weight part: PC resin 17 parts, PBT resin 13 parts, polyvinyl chloride 11 parts, plasticizer 14 parts, calcium carbonate 13 parts , 8 parts of butyl benzyl phthalate, 17 parts of micron SiO2 powder, 25 parts of sodium hexametaphosphate, 10 parts of sodium alginate, 12 parts of surfactant, 24 parts of dioctyl terephthalate, 8 parts of kaolin 15 parts of quartz sand, 20 parts of antimony trioxide, 10 parts of alumina powder, 29 parts of talcum powder, 20 parts of silicate carrier, 12 parts of nano-silver antibacterial agent and appropriate amount of water;

[0033] Its preparation method comprises the following steps:

[0034] S1: Add PC resin, PBT resin, polyvinyl chloride, plasticizer, calcium carbonate, butyl benzyl phthalate and micron-sized SiO2 powder into the stirring tank for a stirring process until the stirring is un...

Embodiment 3

[0041] Propose a kind of low temperature impact resistant PC and PBT composite material in the present embodiment, comprise the raw material of following weight part: PC resin 18 parts, PBT resin 14 parts, polyvinyl chloride 12 parts, plasticizer 15 parts, calcium carbonate 14 parts , 9 parts of butyl benzyl phthalate, 18 parts of micron SiO2 powder, 26 parts of sodium hexametaphosphate, 11 parts of sodium alginate, 13 parts of surfactant, 25 parts of dioctyl terephthalate, 9 parts of kaolin 16 parts of quartz sand, 21 parts of antimony trioxide, 11 parts of alumina powder, 30 parts of talcum powder, 21 parts of silicate carrier, 13 parts of nano-silver antibacterial agent and appropriate amount of water;

[0042] Its preparation method comprises the following steps:

[0043]S1: Add PC resin, PBT resin, polyvinyl chloride, plasticizer, calcium carbonate, butyl benzyl phthalate and micron-sized SiO2 powder into the stirring tank for a stirring process until the stirring is unif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com