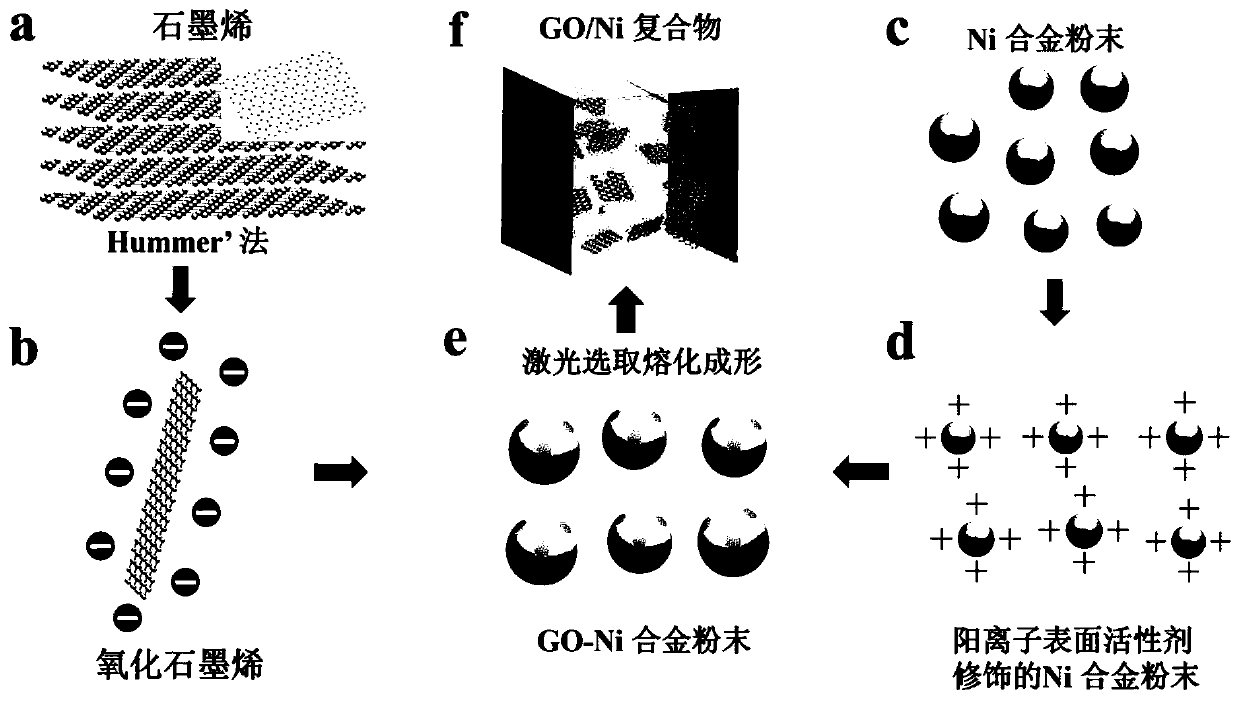

Preparation method and application of oxidized graphene reinforced nickel base composite powder

A composite powder and graphene technology, which is applied in the field of graphene-reinforced nickel-based alloy composite materials, can solve the problems of inability to form complex nickel-based alloy parts, poor graphene dispersion, and low process efficiency, so as to prevent agglomeration, disperse The effect of uniformity and improvement of strengthening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of graphene oxide reinforced nickel-based composite material, comprising the steps of:

[0027] (1) A step for preparing graphene oxide: 1.0 g of sodium nitrate, 1.0 g of graphite and 46 mL of concentrated sulfuric acid were stirred in an ice-water bath for 15 minutes. Slowly add 6.0 g of potassium permanganate in an ice-water bath to obtain a purple-green mixed solution, and control the temperature not to exceed 20°C. After removing the ice-water bath, the mixture was stirred in a 35±5°C water bath for 1 hour to form a thick paste. Then, 40 mL of distilled water was added slowly, the temperature was raised to 90±5°C, and the mixture was stirred at this temperature for 30 minutes. Finally, add 100mL of distilled water, then slowly add 6mL of hydrogen peroxide (30wt.%), after the color of the solution changes from dark brown to bright yellow, the resulting mixed solution is washed several times with 3% hydrochloric acid and distilled water until the...

Embodiment 1

[0046] Embodiments of the present invention provide a method for preparing graphene-reinforced nickel-based composite materials, specifically as follows:

[0047] (1) A step for preparing graphene oxide: 1.0 g of sodium nitrate, 1.0 g of graphite and 46 mL of concentrated sulfuric acid were stirred in an ice-water bath for 15 minutes. Slowly add 6.0 g of potassium permanganate in an ice-water bath to obtain a purple-green mixed solution, and control the temperature not to exceed 20°C. After removing the ice-water bath, the mixture was stirred in a 35±5°C water bath for 1 hour to form a thick paste. Then, 40 mL of distilled water was added slowly, the temperature was raised to 90±5°C, and the mixture was stirred at this temperature for 30 minutes. Finally, 100 mL of distilled water was added, followed by the slow addition of 6 mL of hydrogen peroxide (30 wt.%). After the color of the solution changed from dark brown to bright yellow, the resulting mixed solution was washed se...

Embodiment 2

[0060] Embodiments of the present invention provide a method for preparing graphene-reinforced nickel-based composite materials, specifically as follows:

[0061] (1) A step for preparing graphene oxide: 1.0 g of sodium nitrate, 1.0 g of graphite and 46 mL of concentrated sulfuric acid were stirred in an ice-water bath for 15 minutes. Slowly add 6.0 g of potassium permanganate in an ice-water bath to obtain a purple-green mixed solution, and control the temperature not to exceed 20°C. After removing the ice-water bath, the mixture was stirred in a 35±5°C water bath for 1 hour to form a thick paste. Then, 40 mL of distilled water was added slowly, the temperature was raised to 90±5°C, and the mixture was stirred at this temperature for 30 minutes. Finally, 100 mL of distilled water was added, followed by the slow addition of 6 mL of hydrogen peroxide (30 wt.%). After the color of the solution changed from dark brown to bright yellow, the resulting mixed solution was washed se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com