Nanocrystalline alloy magnetic core and preparation method thereof

A nanocrystalline alloy and magnetic core technology, which is applied in the fields of transformer/inductor magnetic core, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the problem of low relaxation frequency of iron-based soft magnetic alloy materials and cannot meet the requirements of high-frequency transformers. Use, high frequency loss and other problems, to achieve the effect of broadening the product market and application prospects, low high frequency loss, and improving the grain nucleation density and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] This implementation provides a high relaxation frequency nanocrystalline magnetic core for a high frequency transformer. The preparation method of the magnetic core is as follows.

[0065] (1) First, the alloy composition selects Fe 76 Si 13 B 8 Nb 2 Cu 1 , using rapid cooling technology to prepare quenched alloy strips, the specific steps are: Fe, Si, B, Cu and Nb of industrial raw materials are batched according to the components of this embodiment; raw materials with a good ratio are put into an induction melting furnace In the aluminum crucible inside, high temperature melting and heat preservation for 15 minutes, then the melted mixture is poured into a copper mold and cooled to prepare a master alloy steel ingot with uniform composition. The roll speed was 30 m / s). Denoted as the quenched alloy strip M1, the thickness of the quenched alloy strip M1 is 20 microns.

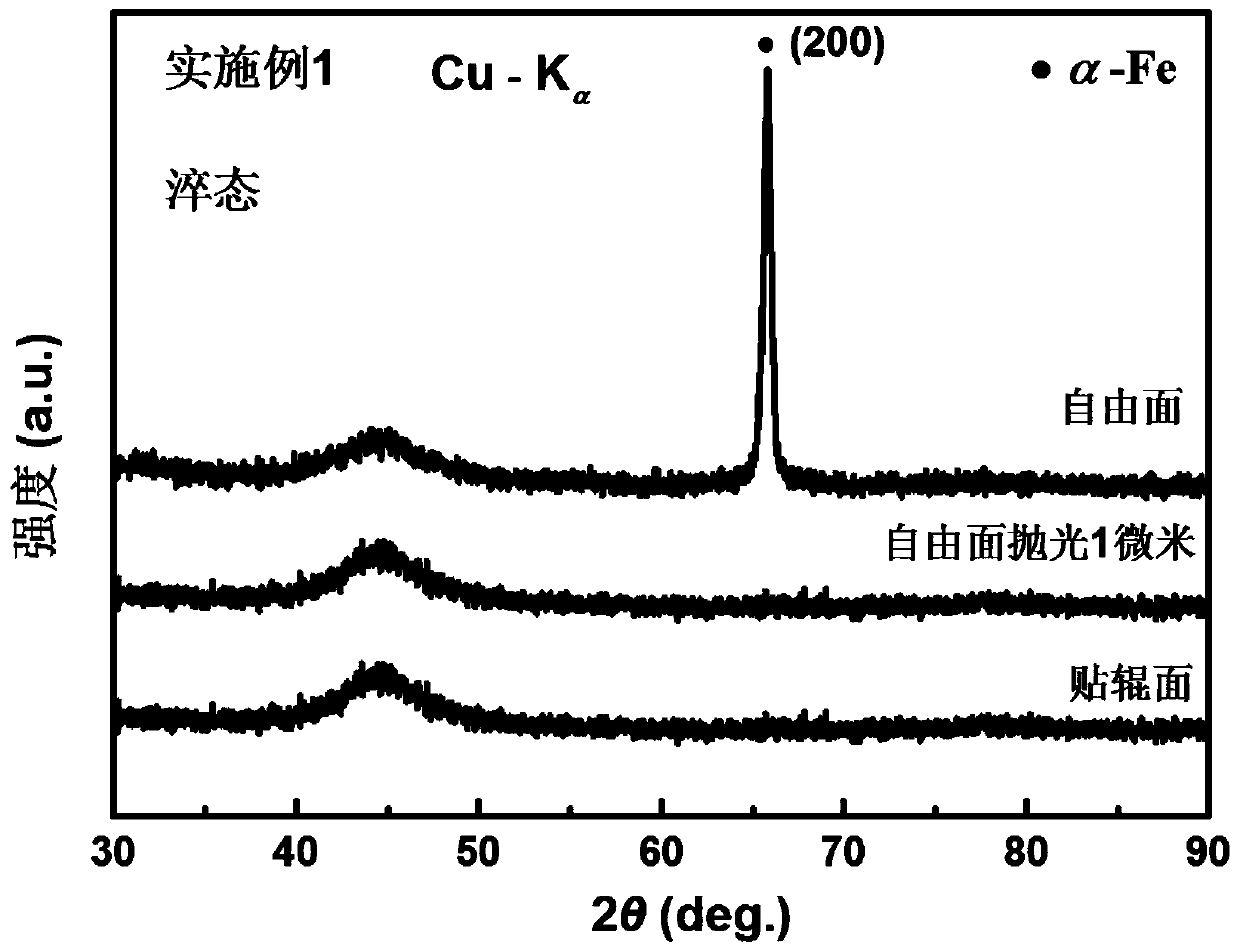

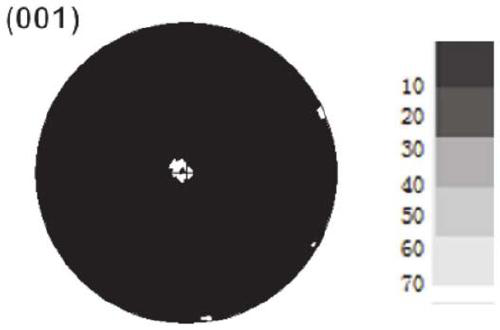

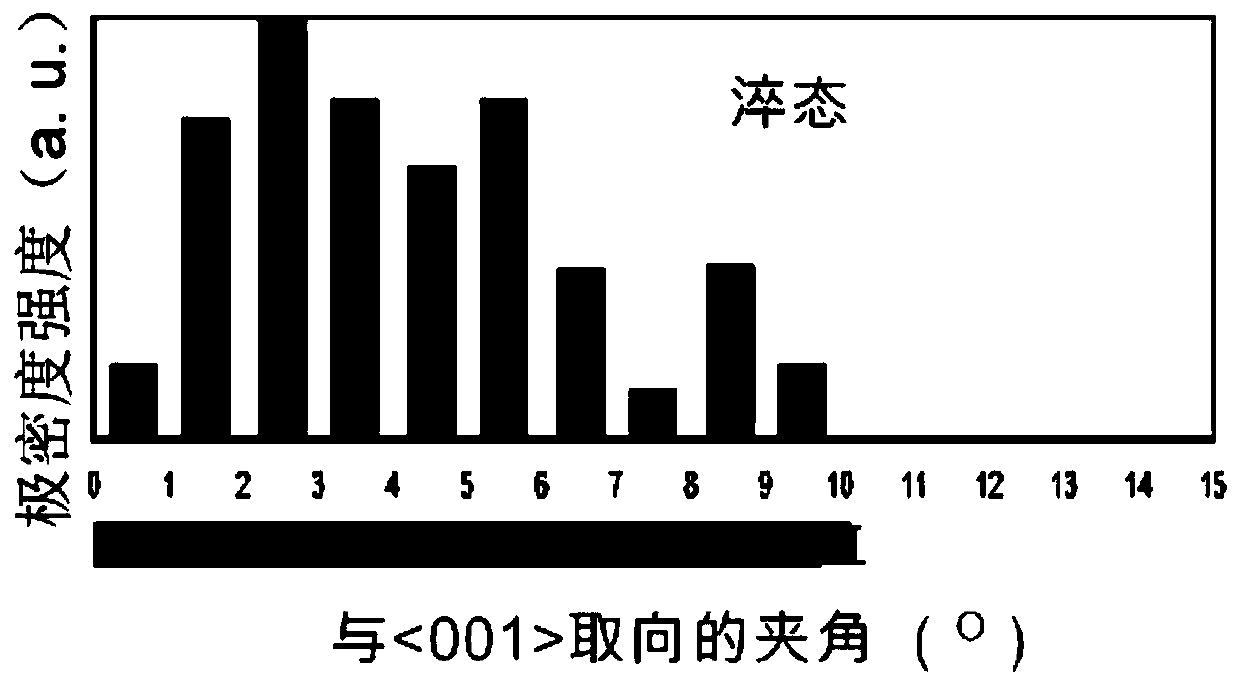

[0066] Carry out XRD test to this as-quenched alloy strip M1, detect its microstructure, the ...

Embodiment 2

[0078] This implementation provides a high relaxation frequency nanocrystalline magnetic core for a high frequency transformer. The preparation method of the magnetic core is as follows.

[0079] (1) First, the alloy composition selects Fe 75.5 Si 13 B 8 Nb 2 Cu 1 (VCAl) 0.5 , using rapid cooling technology to prepare quenched alloy strip, the specific steps are basically the same as in Example 1, the difference is that the copper roll speed is 35m / s. Denoted as quenched alloy strip M2. The as-quenched alloy strip M2 has a strip thickness of 18 microns.

[0080] Carry out XRD test to this quenched alloy strip M2, observe its microstructure, the result is as follows Figure 12 shown. The XRD pattern of the free surface and the rolled surface of the as-quenched alloy strip M2 shows that it has a broadened diffuse diffraction peak at 45°; indicating that the microstructure of all regions of the as-quenched strip is completely amorphous .

[0081] (2) Then, enclose and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com