Preparation method of iron-containing porphyrin/carbon nano tube composite cathode material and application of composite cathode material in lithium-sulfur battery cathode

A carbon nanotube composite, cathode material technology, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve problems such as high cost and inability to achieve commercial use, achieve low cost, improve Coulomb efficiency and cycle stability, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

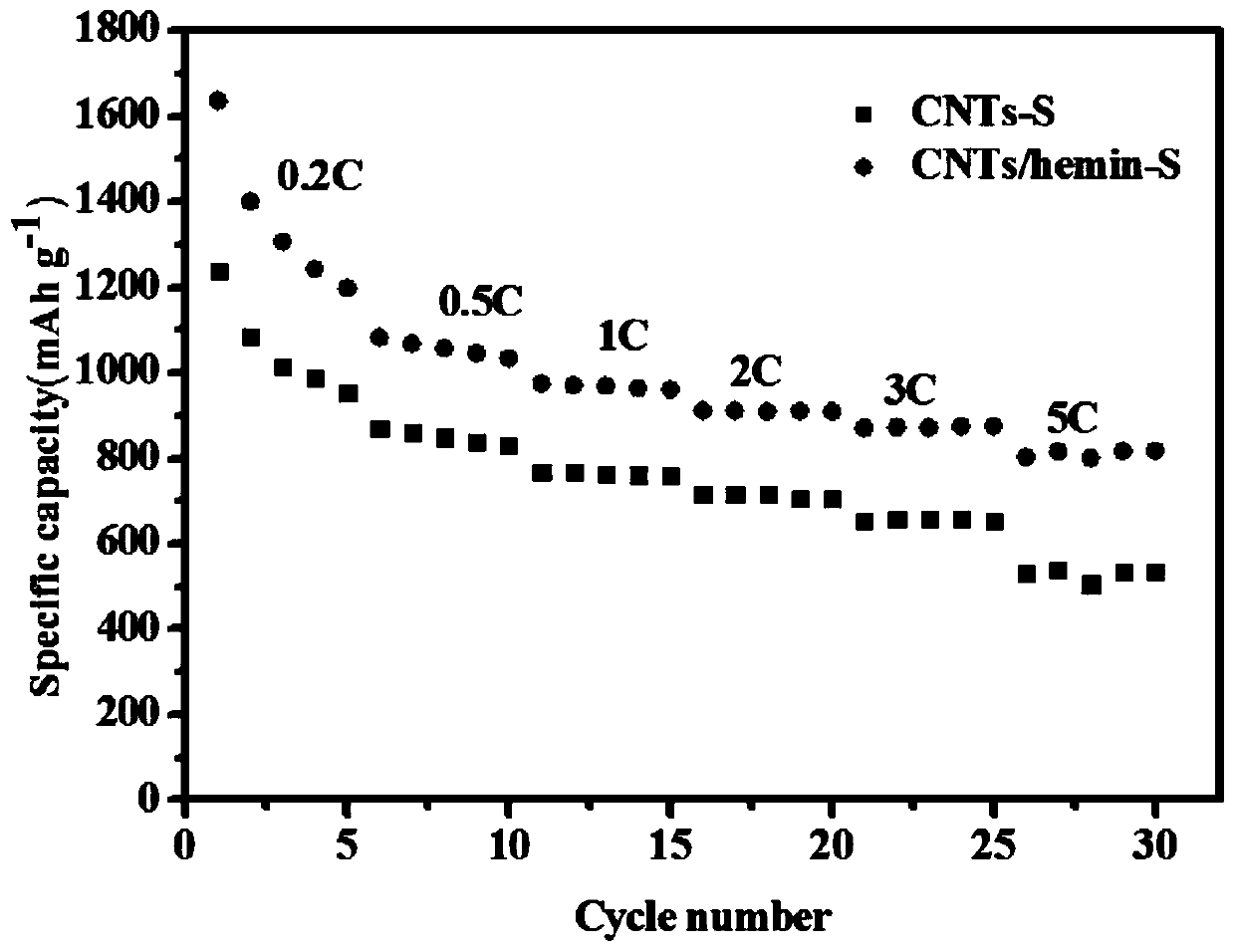

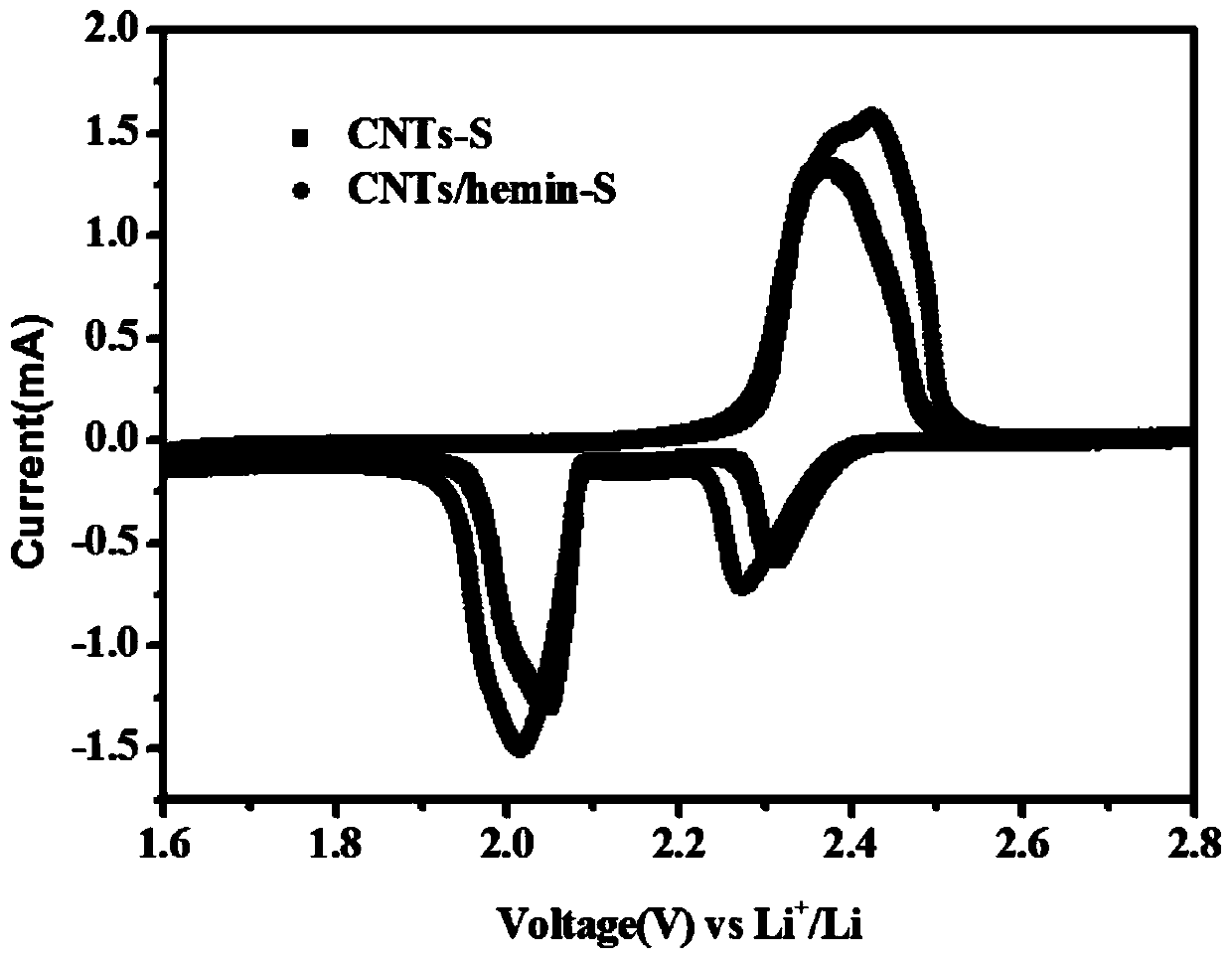

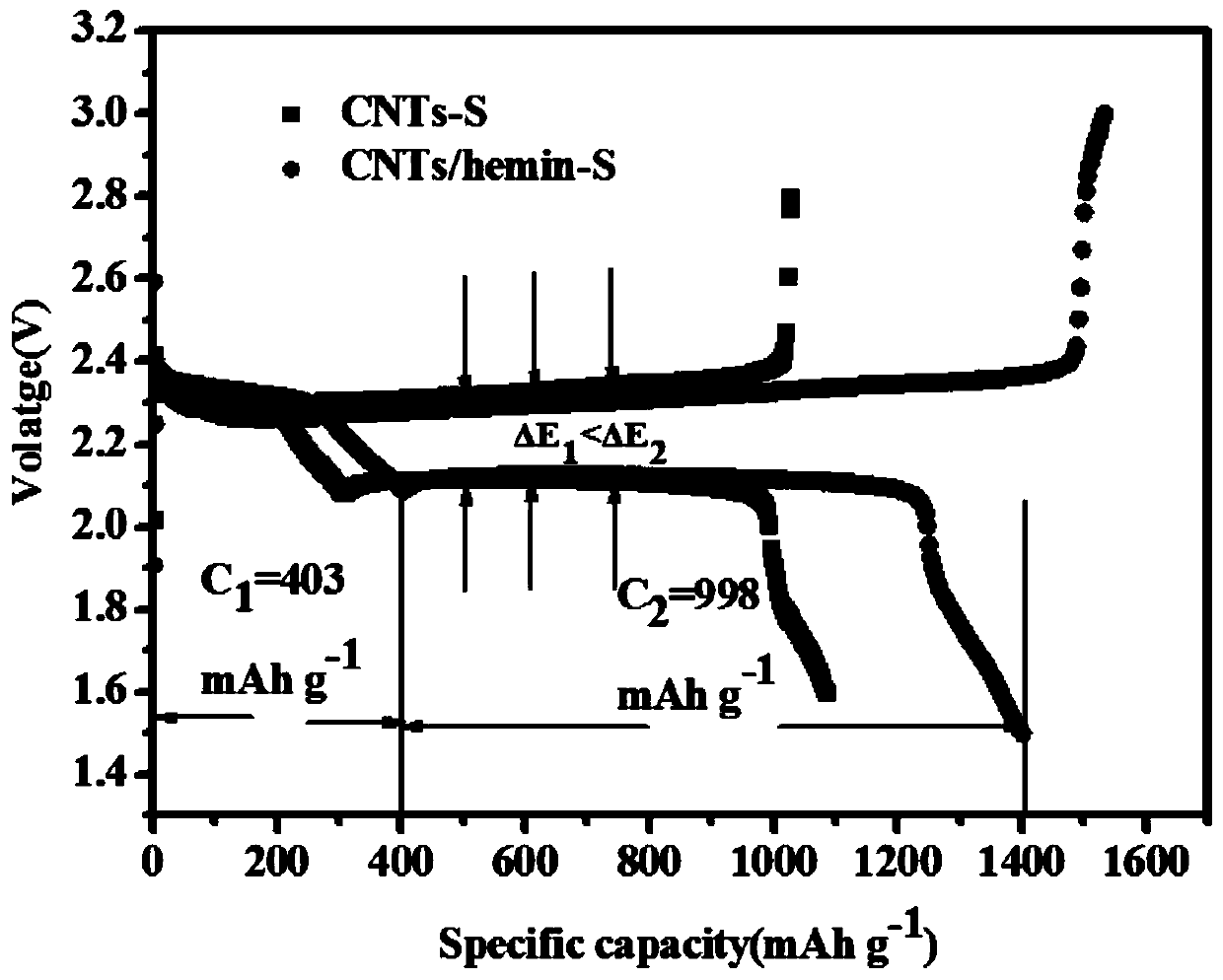

[0031] Example 1: Preparation of hemin and carbon nanotube sulfur-loaded composite cathode material and its application in lithium-sulfur batteries

[0032] (1) Preparation of carbon nanotube sulfur-loaded composite cathode material:

[0033] Carbon nanotubes and elemental sulfur are mixed at a mass ratio of 1:1 to 4, and after uniform grinding, the mass ratio of material to liquid (that is, the sum of the mass of carbon tubes or graphene materials and elemental sulfur to CS 2 The mass ratio) 1:10~15 add CS 2 Stir in medium, then place at 10-30°C to CS 2 After the volatilization is complete, the remaining substances are kept in an oven at 120-160°C for 8-12 hours, and then cooled to room temperature to obtain the carboxylated multi-walled carbon nanotube negative sulfur composite material;

[0034] In this embodiment, equivalent parameters of graphene can also be used to replace carbon nanotubes.

[0035] (2) Preparation of hemin and carbon nanotube sulfur-loaded composite ...

Embodiment 2

[0040] Example 2: Preparation of heme and carbon tube sulfur-loaded composite cathode material and its application in lithium-sulfur batteries

[0041] (1) Preparation of carbon nanotube sulfur-loaded composite cathode material:

[0042] Hydroxylated multi-walled carbon nanotubes and elemental sulfur are mixed at a mass ratio of 1:1 to 4, and after uniform grinding, the mass ratio of material to liquid (that is, the sum of the mass of carbon tubes or graphene materials and elemental sulfur to CS 2 The mass ratio) 1:10~15 add CS 2 Stir in medium, then place at 10-30°C to CS 2 After the volatilization is complete, the remaining substances are kept in an oven at 120-160°C for 8-12 hours, and then cooled to room temperature to obtain the hydroxylated multi-walled carbon nanotube negative sulfur composite material;

[0043] In this embodiment, equivalent parameters of graphene can also be used to replace carbon nanotubes.

[0044] (2) Preparation of composite cathode material of...

Embodiment 3

[0049] Example 3: Preparation of m-tetraphenylporphyrin ferric chloride and carbon tube sulfur-loaded composite cathode material and its application in lithium-sulfur batteries

[0050] (1) Preparation of carboxylated multi-walled carbon nanotube sulfur-loaded composite cathode material:

[0051] Carboxylated multi-walled carbon nanotubes and elemental sulfur are mixed at a mass ratio of 1:1 to 4, and after uniform grinding, the mass ratio of material to liquid (that is, the sum of the mass of carbon tubes or graphene materials and elemental sulfur to CS 2 The mass ratio) 1:10~15 add CS 2 Stir in medium, then place at 10-30°C to CS 2 After the volatilization is complete, the remaining substances are kept in an oven at 120-160°C for 8-12 hours, and then cooled to room temperature to obtain the carboxylated multi-walled carbon nanotube negative sulfur composite material;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com