Lithium-sulphur battery cathode material and preparation method thereof

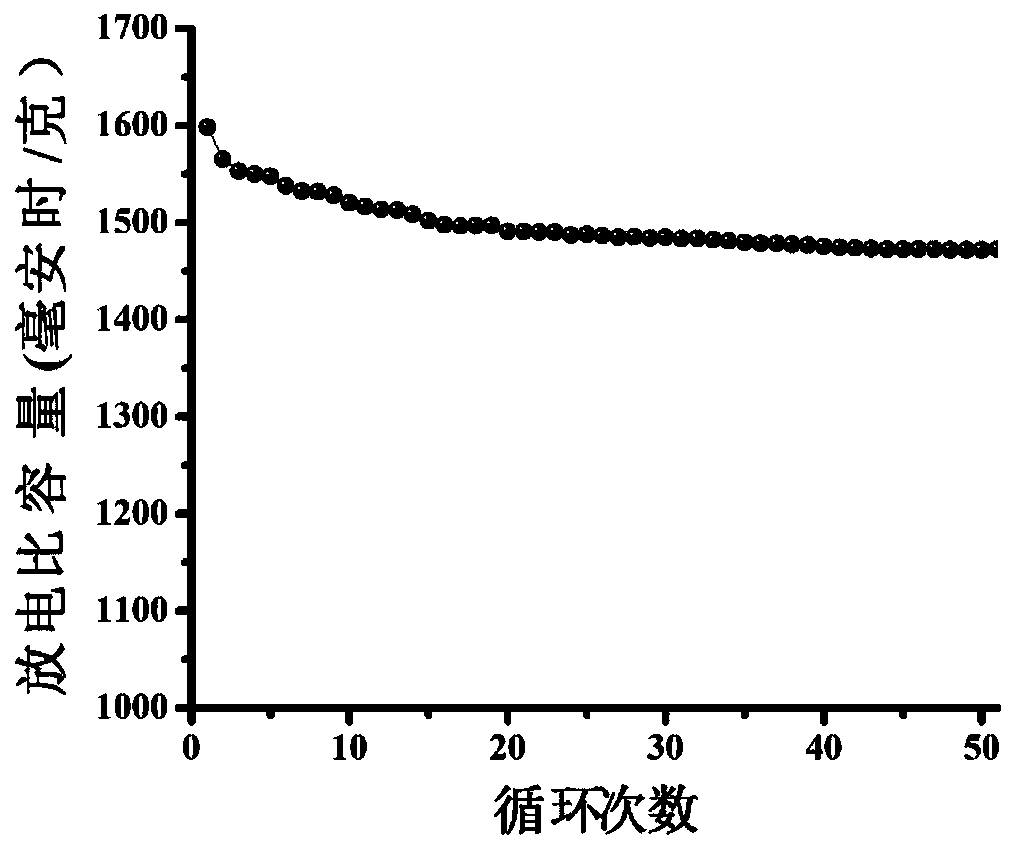

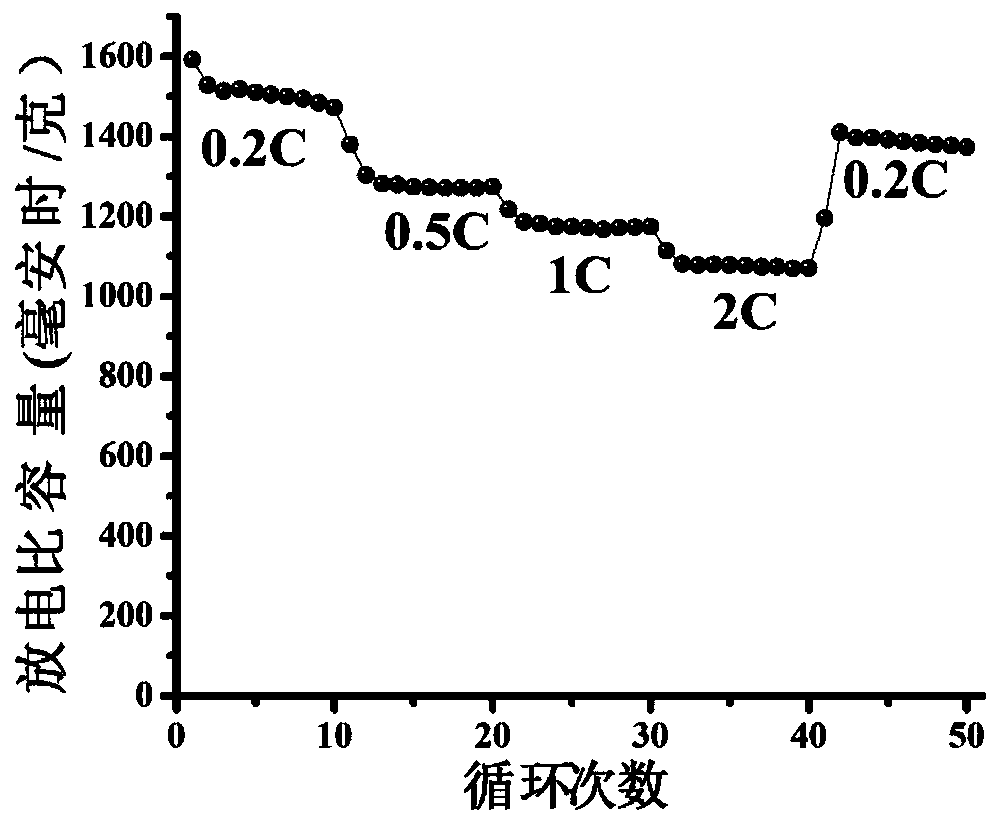

A cathode material, lithium-sulfur battery technology, applied in the field of material chemistry, can solve the problems of obvious shuttle effect, poor cycle stability, low sulfur load, etc., and achieve the effects of shortened transmission path, good cycle life, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of nickel oxide double-layer hollow spheres:

[0024] 15 g of glucose was dissolved in 150 mL of deionized water, placed in a reaction kettle, and hydrothermally reacted at 180° C. for 3 hours. After the reaction was completed, it was cooled at room temperature. The obtained suspension was centrifuged to collect the product, washed three times with deionized water, and dried at 60° C. to obtain carbon sphere powder for later use. Take 1.5 g of carbon ball powder and 1.5 g of nickel acetate in 50 mL of deionized water, ultrasonically disperse for 50 min, stir for 1 hour under magnetic stirring conditions, and then dry in an oven at 60 °C. Then, the product obtained by drying was placed in a tube furnace, heated to 500°C at a heating rate of 1°C / min under air conditions, kept for 2 hours and then cooled at room temperature.

[0025] (2) Preparation of nickel oxide-nickel sulfide composite material:

[0026] Take 0.8 g of the nickel oxide double-layer hol...

Embodiment 2

[0032] (1) Preparation of nickel oxide double-layer hollow spheres:

[0033] 10 g of glucose was dissolved in 100 mL of deionized water, placed in a reaction kettle, and hydrothermally reacted at 180° C. for 2 hours. After the reaction was completed, it was cooled at room temperature. The obtained suspension was centrifuged to collect the product, washed three times with deionized water, and dried at 60° C. to obtain carbon sphere powder for later use. Take 1 g of carbon ball powder and 1 g of nickel acetate in 40 mL of deionized water, ultrasonically disperse for 30 min, stir under magnetic stirring for 1 hour, and then place it in an oven to dry at 60 °C. Then, the product obtained by drying was placed in a tube furnace, heated to 400°C at a heating rate of 1°C / min under air conditions, kept for 1 hour and then cooled at room temperature.

[0034] (2) Preparation of nickel oxide-nickel sulfide composite material:

[0035]Take 0.5 g of the nickel oxide double-layer hollow s...

Embodiment 3

[0039] (1) Preparation of nickel oxide double-layer hollow spheres:

[0040] 20 g of glucose was dissolved in 200 mL of deionized water, placed in a reaction kettle, and hydrothermally reacted at 200° C. for 4 hours. After the reaction was completed, it was cooled at room temperature. The obtained suspension was centrifuged to collect the product, washed three times with deionized water, and dried at 60° C. to obtain carbon sphere powder for later use. Take 2g of carbon ball powder and 2g of nickel acetate into 60mL of deionized water, ultrasonically disperse for 60 minutes, stir under magnetic stirring for 2 hours, and then place it in an oven to dry at 80°C. Then, the product obtained by drying was placed in a tube furnace, heated to 600°C at a heating rate of 2°C / min under air conditions, kept for 2 hours and then cooled at room temperature.

[0041] (2) Preparation of nickel oxide-nickel sulfide composite material:

[0042] Take 1 g of the nickel oxide double-layer hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com