Nickel-based catalyst for dry reforming of methane and carbon dioxide and preparation method and application thereof

A technology of nickel-based catalyst and carbon dioxide, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. Problems such as high energy consumption, to avoid particle accumulation, expand industrial applications, and eliminate carbon deposition and deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

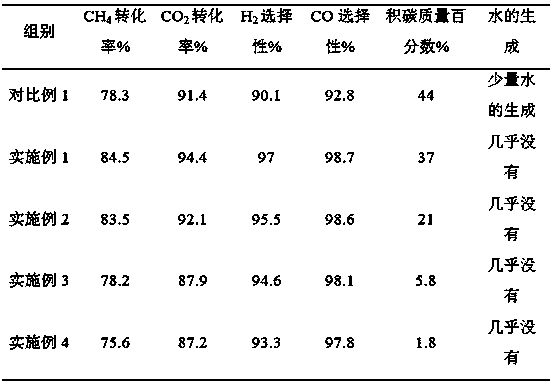

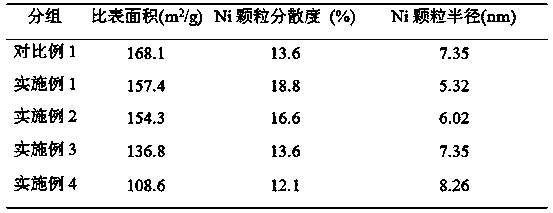

Embodiment 1

[0031] Example 1 A methane carbon dioxide dry reforming catalyst

[0032] Prepare as follows:

[0033] (1) The ϒ-Al 2 o 3 Put it into a muffle furnace, program the temperature from room temperature to 800 °C at a rate of 4 °C / min, and then calcine at a constant temperature for 4 hours to obtain pretreated ϒ-Al 2 o 3 (The water absorption rate was determined to be 1.4 g / g);

[0034] (2) Measure 3.07 g of nickel nitrate hexahydrate and 0.75 g of yttrium nitrate hexahydrate into 7 mL of deionized water weighed in advance, stir and dissolve until transparent, and then sonicate for 30 min to obtain solution A;

[0035] (3) Weigh 5 g of the pretreated ϒ-Al obtained in step (1) 2 o 3 , add solution A to the pretreated ϒ-Al at a rate of 0.5-1.0 mL / min 2 o3 In, stir while adding solution A, make solution A and pretreated ϒ-Al 2 o 3 The mixed sample was stirred evenly until it became a paste, and then ultrasonicated for 30 min. The sonicated paste was impregnated in the dark f...

Embodiment 2

[0038] Example 2 A methane carbon dioxide dry reforming catalyst

[0039] Prepare as follows:

[0040] (1) The ϒ-Al 2 o 3 Put it into a muffle furnace, program the temperature from room temperature to 800 °C at a rate of 4 °C / min, and then calcine at a constant temperature for 4 hours to obtain pretreated ϒ-Al 2 o 3 (The water absorption rate was determined to be 1.4 g / g);

[0041] (2) Measure 3.15 g of nickel nitrate hexahydrate and 1.28 g of yttrium nitrate hexahydrate into 7 mL of deionized water weighed in advance, stir and dissolve until transparent, and then sonicate for 30 min to obtain solution A;

[0042] (3) Weigh 5 g of the pretreated ϒ-Al obtained in step (1) 2 o 3 , add solution A to the pretreated ϒ-Al at a rate of 0.5-1.0 mL / min 2 o 3 In, stir while adding solution A, make solution A and pretreated ϒ-Al 2 o 3 The mixed sample was stirred evenly until it became a paste, and then ultrasonicated for 30 min. The sonicated paste was impregnated in the dark...

Embodiment 3

[0045] Example 3 A methane carbon dioxide dry reforming catalyst

[0046] Prepare as follows:

[0047] (1) The ϒ-Al 2 o 3 Put it into a muffle furnace, program the temperature from room temperature to 800 °C at a rate of 4 °C / min, and then calcine at a constant temperature for 4 hours to obtain pretreated ϒ-Al 2 o 3 (The water absorption rate was determined to be 1.4 g / g);

[0048] (2) Measure 3.34 g of nickel nitrate hexahydrate and 2.72 g of yttrium nitrate hexahydrate into 7 mL of deionized water weighed in advance, stir and dissolve until transparent, and then sonicate for 30 min to obtain solution A;

[0049] (3) Weigh 5 g of the pretreated ϒ-Al obtained in step (1) 2 o 3 , add solution A to the pretreated ϒ-Al at a rate of 0.5-1.0 mL / min 2 o 3 In, stir while adding solution A, make solution A and pretreated ϒ-Al 2 o 3 The mixed sample was stirred evenly until it became a paste, and then ultrasonicated for 30 min. The sonicated paste was impregnated in the dark...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com