System and method for synergistically treating desulfurization waste water and enhancing agglomeration and removal of fine particles

A technology for fine particles and desulfurization wastewater, applied in chemical instruments and methods, solid separation, electrostatic effect separation, etc., can solve the problems of poor atomization effect of droplets, poor agglomeration effect of fine particles, and low effective collision efficiency of particles, etc., to achieve Promote agglomeration and removal, achieve secondary utilization, and fully atomize and disperse the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

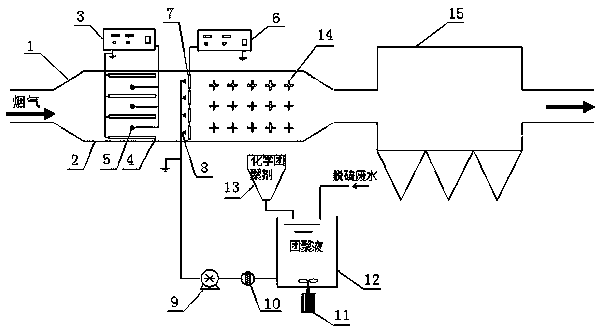

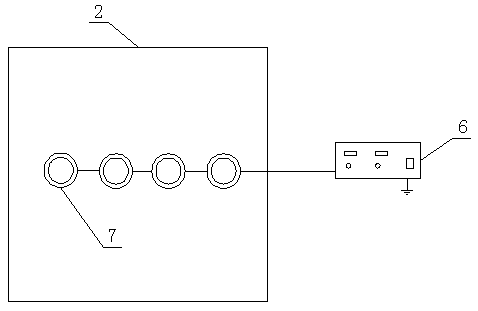

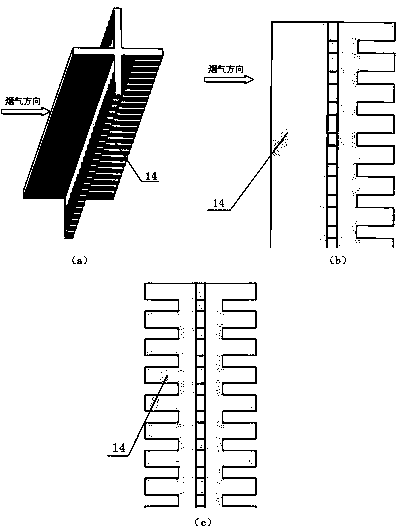

[0033]A system for synergistically treating desulfurization wastewater and strengthening the agglomeration and removal of fine particles, the system includes a coagulation and growth system 1, and the coagulation and growth system 1 includes a shell 2 with a square cross section, a particle charging device, an agglomeration Liquid atomization charging device and turbulent flow agglomeration device; the left side of the housing is the smoke inlet, and the right side is the smoke outlet, both of which are in the shape of a trumpet mouth, and the small mouth is facing outward; The inner cavity of the shell is divided into particle charging area, agglomeration liquid atomization charging area and turbulent agglomeration area from left to right;

[0034] The particle charging device adopts a line-plate structure arrangement, and the particle charging device includes a first negative voltage DC high-voltage power supply 3 and several plate electrodes 4, the plate electrodes 4 are mad...

Embodiment 2

[0048] The dusty flue gas is produced by the coal-fired boiler, and the flue gas velocity in the shell is 12m / s. After the boiler is running stably, a certain amount of fly ash is added to the flue gas to simulate the flue gas generated by the actual power plant combustion to ensure the concentration of fine particles required for the test. The smoke sampler is used to sample and test the total dust concentration in the flue gas. ELPI online test PM 2.5 Concentration and particle size distribution. After testing, the total dust concentration in the original flue gas is 10.5g / m 3 , PM 10 The total mass concentration is 235.5mg / m 3 , with a number concentration of 5.3´10 7 / cm 3 , before the system and method of the present invention are not used, the flue gas directly enters the electrostatic precipitator and is discharged, and the total dust concentration in the flue gas is 0.51g / m 3 , PM 10 The mass concentration is 20.4mg / m 3 , with a number concentration of 5.1´10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com