Decomposition crystallization aid for producing aluminum oxide

A crystallization aid, alumina technology, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve the problem of unsatisfactory particle size improvement, poor dispersion performance, poor water solubility or alkali solubility and other problems, achieve good water solubility and alkali solubility, solve the effect of improving the decomposition rate, and solving the effect of long and thick particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The mass percentage composition of the decomposing crystallization aid of the present embodiment is as follows:

[0045] Methanol 45%

[0046] Sodium Oleate 30%

[0047] Triethanolamine 25%.

Embodiment 2

[0049] The mass percentage composition of the decomposing crystallization aid of the present embodiment is as follows:

[0050] Methanol 30%

[0051] Ethanol 30%

[0052] Diethanolamine 40%.

Embodiment 3

[0054] The mass percentage composition of the decomposing crystallization aid of the present embodiment is as follows:

[0055] Glycerol 45%

[0056] Polyvinyl alcohol 15%

[0057] Sodium Oleate 40%.

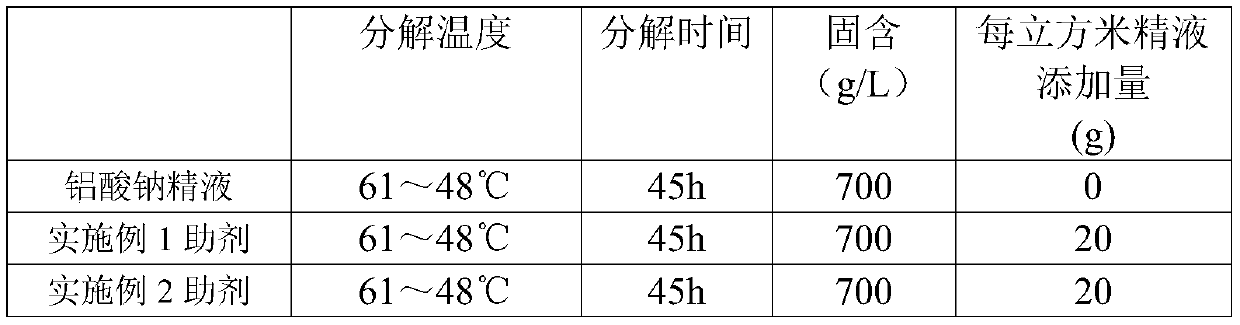

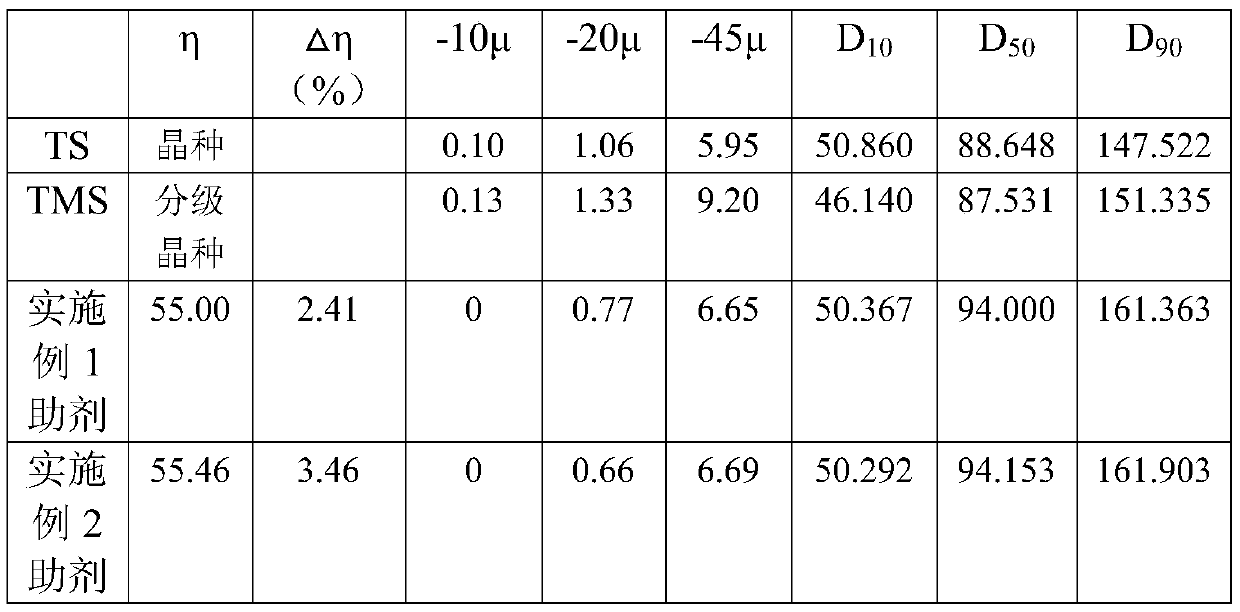

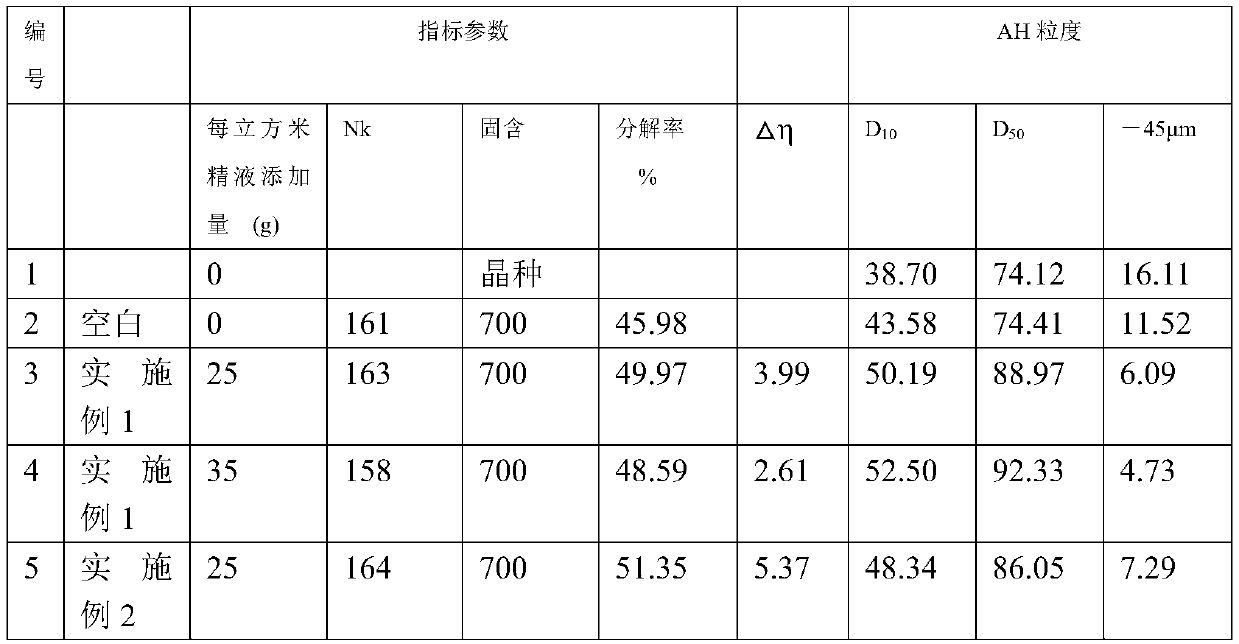

[0058] Relevant effect tests were carried out using the decomposition and crystallization aids provided in Examples 1-3, as follows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com