Efficient preparation technology of high-quality hickory nut oil

A technology of pecan oil and preparation process, which is applied in the direction of fat oil/fat refining, fat oil/fat production, fat production, etc., can solve the problems of high production temperature, rising pressure and energy consumption, low oil yield, etc., and achieve oil quality. Good, mild conditions, high oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

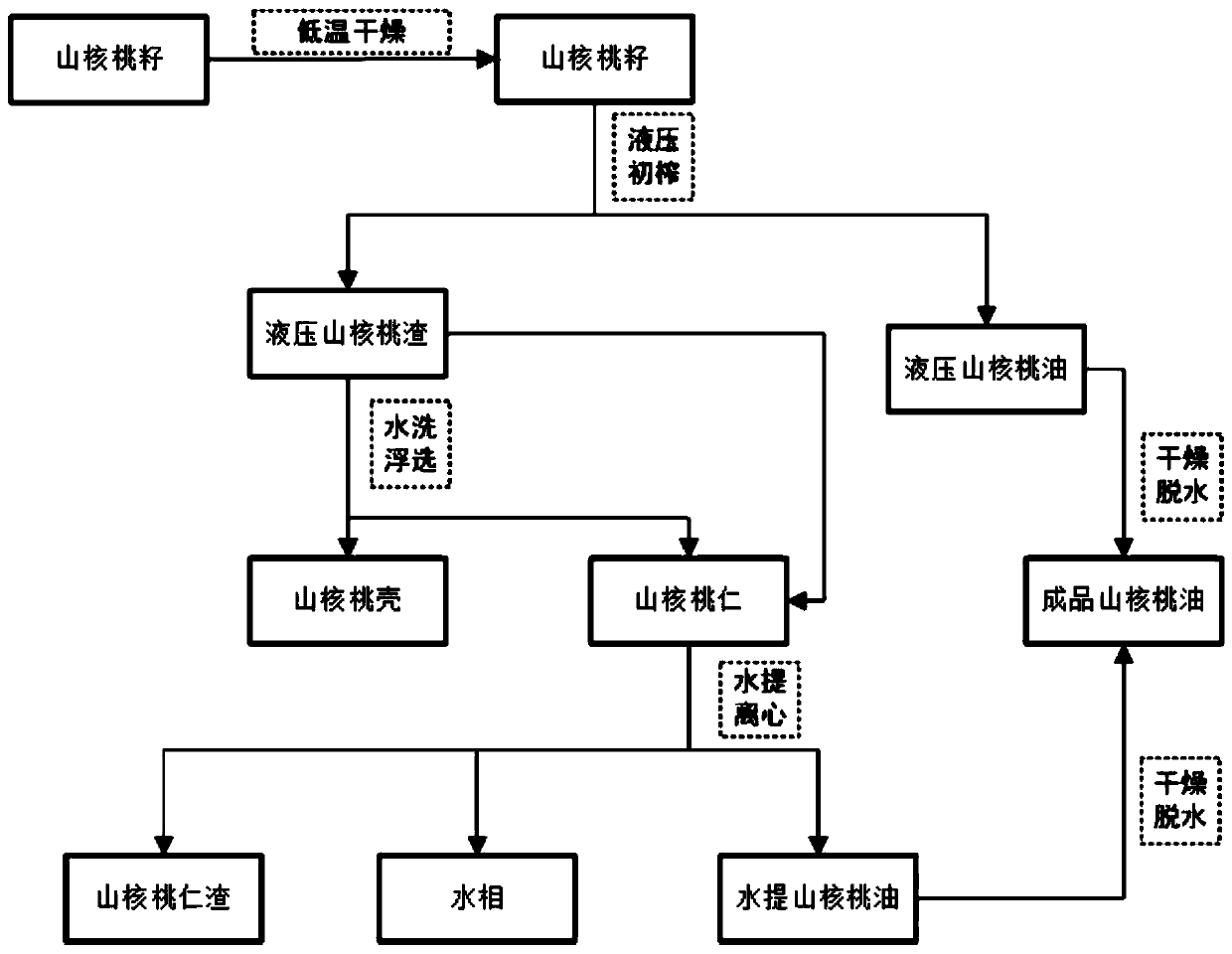

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Take hickory kernels and dry them in a dryer at 60°C until the moisture content is about 5%. After wrapping the cakes, put them in a vertical hydraulic oil press and squeeze them for about 20 minutes. Vacuum drying for 30min dehydration, the oil is hickory cold pressed oil. After hydraulic pressure, the residual oil in the residual cake is about 25%. Add pH 3.5 deionized water according to the ratio of material to liquid 1:4 (w / v), homogenize at 2000rpm for 2min, filter with plate and frame, and centrifuge the filtrate at 3000rpm for 10 minutes. ℃ vacuum drying for 30min dehydration, the oil is hickory water extraction oil. The calculated total oil yield is about 89%. The cold-pressed hickory oil and the water-extracted oil were tested respectively, and the acid values were 0.20 and 0.15 mgKOH / g, and the peroxide values were 2.1 and 1.9 mmol / kg. Its quality meets the relevant requirements of "GB2716-2018 National Food Safety Standard Edible Vegetable Oil...

Embodiment 2

[0024] Example 2: Take pecan seeds and dry them in a dryer at 60°C until the moisture content is about 6%, mechanically break the shells until the shell-to-kernel ratio is about 1:9, wrap the cakes and put them in a vertical hydraulic oil press for about 30 minutes , collect the pressed oil, filter, and vacuum-dry the oil sample at 90°C for 30 minutes to dehydrate. The oil is cold-pressed hickory oil. After hydraulic pressure, the residual oil in the residual cake is about 20%. Add deionized water according to the material-to-liquid ratio of 1:4 (w / v), stir and disperse in a 1000rpm mixer, remove the residual husk after standing, and adjust the solution to about pH 3.5. Homogenize at 2000rpm for 2 minutes, centrifuge at 3000rpm for 30 minutes, and vacuum-dry the upper oil layer at 90°C for 30 minutes to dehydrate. The calculated total oil yield is about 90%. The cold-pressed hickory oil and the water-extracted oil were tested respectively, and the acid values were 0.21 and 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com